Required information Sally is making a sine bar, which is used to machine angles on parts (see the given figure). She has a 1.250-inch-thick bar that needs 90° grooves machined into it for precision ground 1.0000-inch diameter cylinders. A sine bar is used by placing different thicknesses under one of the cylinders so that the proper angle is attained. Sally wants the distance between the centers of the cylinders to be D= 5.6 inches. NOTE: This is a multi-part question. Once an answer is submitted, you will be unable to return to this part. -1.0000 Ø Once her sine block is finished, she wants to mill a 22.5° angle on a brass block. What thickness of gage blocks will produce this angle for this sine plate? (Round the final answer to four decimal places.) The required thickness is inches.

Required information Sally is making a sine bar, which is used to machine angles on parts (see the given figure). She has a 1.250-inch-thick bar that needs 90° grooves machined into it for precision ground 1.0000-inch diameter cylinders. A sine bar is used by placing different thicknesses under one of the cylinders so that the proper angle is attained. Sally wants the distance between the centers of the cylinders to be D= 5.6 inches. NOTE: This is a multi-part question. Once an answer is submitted, you will be unable to return to this part. -1.0000 Ø Once her sine block is finished, she wants to mill a 22.5° angle on a brass block. What thickness of gage blocks will produce this angle for this sine plate? (Round the final answer to four decimal places.) The required thickness is inches.

Precision Machining Technology (MindTap Course List)

2nd Edition

ISBN:9781285444543

Author:Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher:Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Chapter6: Milling

Section6.4: Indexing And Rotary Table Operations

Problem 6RQ: If the outside of a 6"-diameter disk is to be milled using a rotary table and a 3/4" diameter...

Related questions

Topic Video

Question

Transcribed Image Text:!

Required information

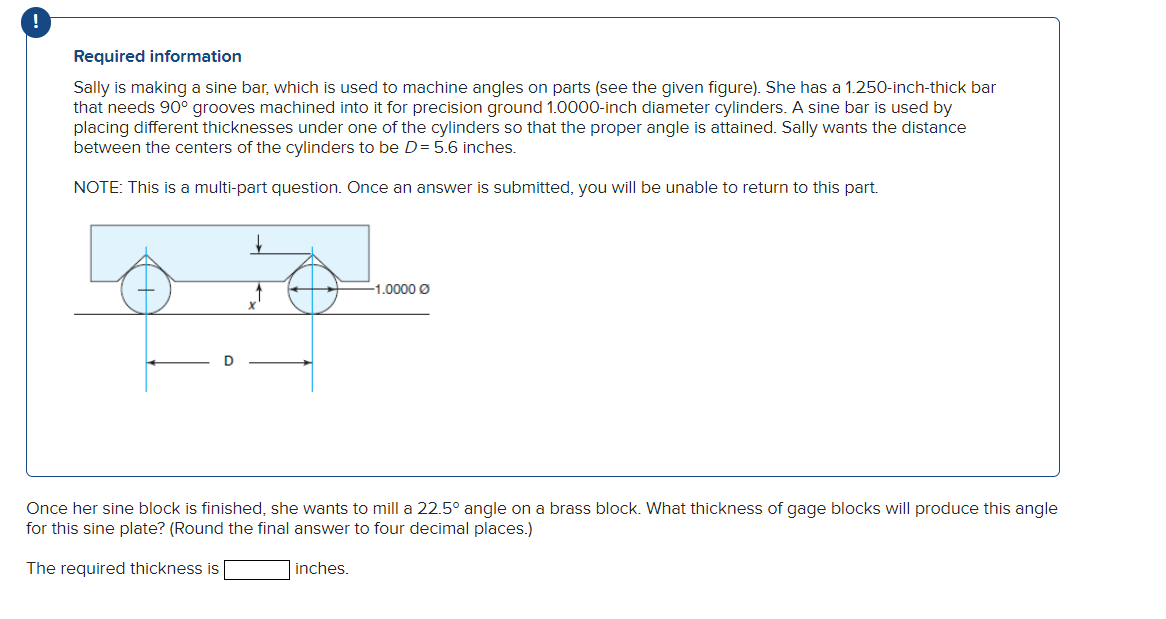

Sally is making a sine bar, which is used to machine angles on parts (see the given figure). She has a 1.250-inch-thick bar

that needs 90° grooves machined into it for precision ground 1.0000-inch diameter cylinders. A sine bar is used by

placing different thicknesses under one of the cylinders so that the proper angle is attained. Sally wants the distance

between the centers of the cylinders to be D = 5.6 inches.

NOTE: This is a multi-part question. Once an answer is submitted, you will be unable to return to this part.

-1.0000 Ø

Once her sine block is finished, she wants to mill a 22.5° angle on a brass block. What thickness of gage blocks will produce this angle

for this sine plate? (Round the final answer to four decimal places.)

The required thickness is

inches.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Precision Machining Technology (MindTap Course Li…

Mechanical Engineering

ISBN:

9781285444543

Author:

Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher:

Cengage Learning

Precision Machining Technology (MindTap Course Li…

Mechanical Engineering

ISBN:

9781285444543

Author:

Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher:

Cengage Learning