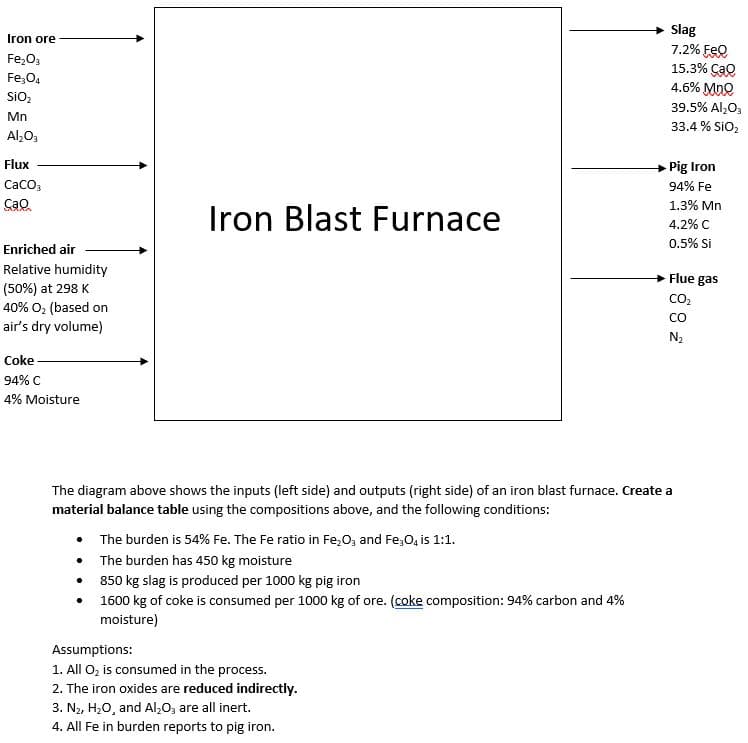

The diagram above shows the inputs (left side) and outputs (right side) of an iron blast furnace. Create a material balance table using the compositions above, and the following conditions: The burden is 54% Fe. The Fe ratio in Fe₂O, and Fe,O, is 1:1. • The burden has 450 kg moisture ⚫ 850 kg slag is produced per 1000 kg pig iron ⚫ 1600 kg of coke is consumed per 1000 kg of ore. (coke composition: 94% carbon and 4% moisture) Assumptions: 1. All O₂ is consumed in the process. 2. The iron oxides are reduced indirectly. 3. N₂, H₂O, and Al₂O, are all inert. 4. All Fe in burden reports to pig iron.

The diagram above shows the inputs (left side) and outputs (right side) of an iron blast furnace. Create a material balance table using the compositions above, and the following conditions: The burden is 54% Fe. The Fe ratio in Fe₂O, and Fe,O, is 1:1. • The burden has 450 kg moisture ⚫ 850 kg slag is produced per 1000 kg pig iron ⚫ 1600 kg of coke is consumed per 1000 kg of ore. (coke composition: 94% carbon and 4% moisture) Assumptions: 1. All O₂ is consumed in the process. 2. The iron oxides are reduced indirectly. 3. N₂, H₂O, and Al₂O, are all inert. 4. All Fe in burden reports to pig iron.

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

Create a material balance table by calculating the weight of each input and output component. Feel free to make additional assumptions if necessary.

Transcribed Image Text:Slag

7.2% Feo

15.3% ÇaQ

4.6% Mne

Iron ore

Fe;O3

Fe,04

SiO,

39.5% Al,0,

Mn

33.4 % SiO,

Al,0,

Flux

Pig Iron

CaCO,

cao.

94% Fe

1.3% Mn

Iron Blast Furnace

4.2% C

0.5% Si

Enriched air

Relative humidity

(50%) at 298 K

40% O, (based on

air's dry volume)

Flue gas

CO,

CO

N2

Coke

94% C

4% Moisture

The diagram above shows the inputs (left side) and outputs (right side) of an iron blast furnace. Create a

material balance table using the compositions above, and the following conditions:

• The burden is 54% Fe. The Fe ratio in Fe,0, and Fe;0, is 1:1.

• The burden has 450 kg moisture

• 850 kg slag is produced per 1000 kg pig iron

• 1600 kg of coke is consumed per 1000 kg of ore. (coke composition: 94% carbon and 4%

moisture)

Assumptions:

1. All O, is consumed in the process.

2. The iron oxides are reduced indirectly.

3. N2, H20, and Al,0, are all inert.

4. All Fe in burden reports to pig iron.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 3 steps with 24 images

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The