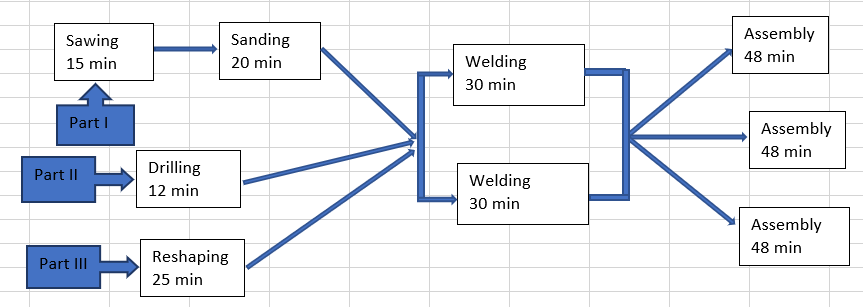

The following flow chart shows the entire manufacturing process at KD Manufacturing, which consists of six independent operations processes (i.e. sawing, sanding, drilling, reshaping, welding, and assembly). The entire process flow starts with the input of three different parts, Part I, Part II and Part III, each entering a different input line. Three parts meet later for the welding, whichever welding station is available (two identical welding stations work independently). After welding is completed, the product is sent to one of the three assembly stations (which are in parallel). The chart also shows the processing time per unit (in minutes) for each operation. Each of sawing, sanding, drilling and reshaping stations is handled by a different worker. Two workers handle welding, each at one welding station. Another three workers handle the assembly process independently, one at each assembly station. To improve the capacity of the entire manufacturing process, the manager decides to shut down one assembly or welding station, and then reassign the worker from this closed station to another process at which a new station will be added. It is assumed that the newly-added station will be identical to, and work independently (i.e. in parallel) with the exisiting station(s) for that process. Do you agree with the manager's decision? If you do, please clearly state which station should be closed and where the new station should be added to. If you don't, explain why. Whether you agree or disagree, you MUST justify your answer with correct calculations and numbers.

The following flow chart shows the entire manufacturing process at KD Manufacturing, which consists of six independent operations processes (i.e. sawing, sanding, drilling, reshaping, welding, and assembly). The entire process flow starts with the input of three different parts, Part I, Part II and Part III, each entering a different input line. Three parts meet later for the welding, whichever welding station is available (two identical welding stations work independently). After welding is completed, the product is sent to one of the three assembly stations (which are in parallel). The chart also shows the processing time per unit (in minutes) for each operation. Each of sawing, sanding, drilling and reshaping stations is handled by a different worker. Two workers handle welding, each at one welding station. Another three workers handle the assembly process independently, one at each assembly station. To improve the capacity of the entire manufacturing process, the manager decides to shut down one assembly or welding station, and then reassign the worker from this closed station to another process at which a new station will be added. It is assumed that the newly-added station will be identical to, and work independently (i.e. in parallel) with the exisiting station(s) for that process. Do you agree with the manager's decision? If you do, please clearly state which station should be closed and where the new station should be added to. If you don't, explain why. Whether you agree or disagree, you MUST justify your answer with correct calculations and numbers.

Trending now

This is a popular solution!

Step by step

Solved in 3 steps