Using your engineering judgment, critical thinking, and common sense, prepare a process flow diagram in a single sheet of paper that accurately captures the process flow narrative below. You may draw this diagram either by hand or by electronic means. === Two conical storage tanks, with equipment number T-101A and T-101B, contain a mixture of liquid hydrocarbons with pour point of 5°C. T-101A/B operate in a 2 x 100% redundancy. To keep the hydrocarbon mixture homogenized, an internal mixer (M-101A/B) is provided in each tank. The contents of the tank are pumped by centrifugal pumps (P-101A/B/C) via a 10" pipe to another conical storage tank (T-102) 1 kilometer away. The pumps operate in a 3 x 50% redundancy. Assuming the Philippines experiences subzero temperatures 3 months a year, the management has decided to also provide a bypass line. This bypass line, which starts from the P-101A/B/C discharge, diverts the flow to a shell and tube heat exchanger (E-101) where it is heated by hot water (tube-side) to prevent waxing/plugging of the pipes. The heated hydrocarbon mixture connects back to the 10" line and go on its way to T-102. The hot water that goes to the tube-side of E-101 comes from a water storage tank (T-901). Clean water from T- 901 is pumped by P-901A/B (2 x 100%), passes through an electric heater (E-901), and goes into E-101. The hot water cycle is a closed loop system - this means the now cooled water from E-101 is recirculated back to the T-901 to be reused. ===== Notes: 1. There is no need to show instruments or process controls for this exercise. 2. Show only important valves that you think will help the reader understand the process described above. 3. Use the following symbols. a. Shell-and-Tube Heat Exchanger Tube side in C. b. Centrifugal Pump Suction Shell side out Conical Tank Shell side in → Discharge Tube side out e. Mixer M f. Valves g. Pipe 8 M-101A T-101A Closed valve Open valve

Using your engineering judgment, critical thinking, and common sense, prepare a process flow diagram in a single sheet of paper that accurately captures the process flow narrative below. You may draw this diagram either by hand or by electronic means. === Two conical storage tanks, with equipment number T-101A and T-101B, contain a mixture of liquid hydrocarbons with pour point of 5°C. T-101A/B operate in a 2 x 100% redundancy. To keep the hydrocarbon mixture homogenized, an internal mixer (M-101A/B) is provided in each tank. The contents of the tank are pumped by centrifugal pumps (P-101A/B/C) via a 10" pipe to another conical storage tank (T-102) 1 kilometer away. The pumps operate in a 3 x 50% redundancy. Assuming the Philippines experiences subzero temperatures 3 months a year, the management has decided to also provide a bypass line. This bypass line, which starts from the P-101A/B/C discharge, diverts the flow to a shell and tube heat exchanger (E-101) where it is heated by hot water (tube-side) to prevent waxing/plugging of the pipes. The heated hydrocarbon mixture connects back to the 10" line and go on its way to T-102. The hot water that goes to the tube-side of E-101 comes from a water storage tank (T-901). Clean water from T- 901 is pumped by P-901A/B (2 x 100%), passes through an electric heater (E-901), and goes into E-101. The hot water cycle is a closed loop system - this means the now cooled water from E-101 is recirculated back to the T-901 to be reused. ===== Notes: 1. There is no need to show instruments or process controls for this exercise. 2. Show only important valves that you think will help the reader understand the process described above. 3. Use the following symbols. a. Shell-and-Tube Heat Exchanger Tube side in C. b. Centrifugal Pump Suction Shell side out Conical Tank Shell side in → Discharge Tube side out e. Mixer M f. Valves g. Pipe 8 M-101A T-101A Closed valve Open valve

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

Transcribed Image Text:6:24

1 of 1

TERM PROJECT

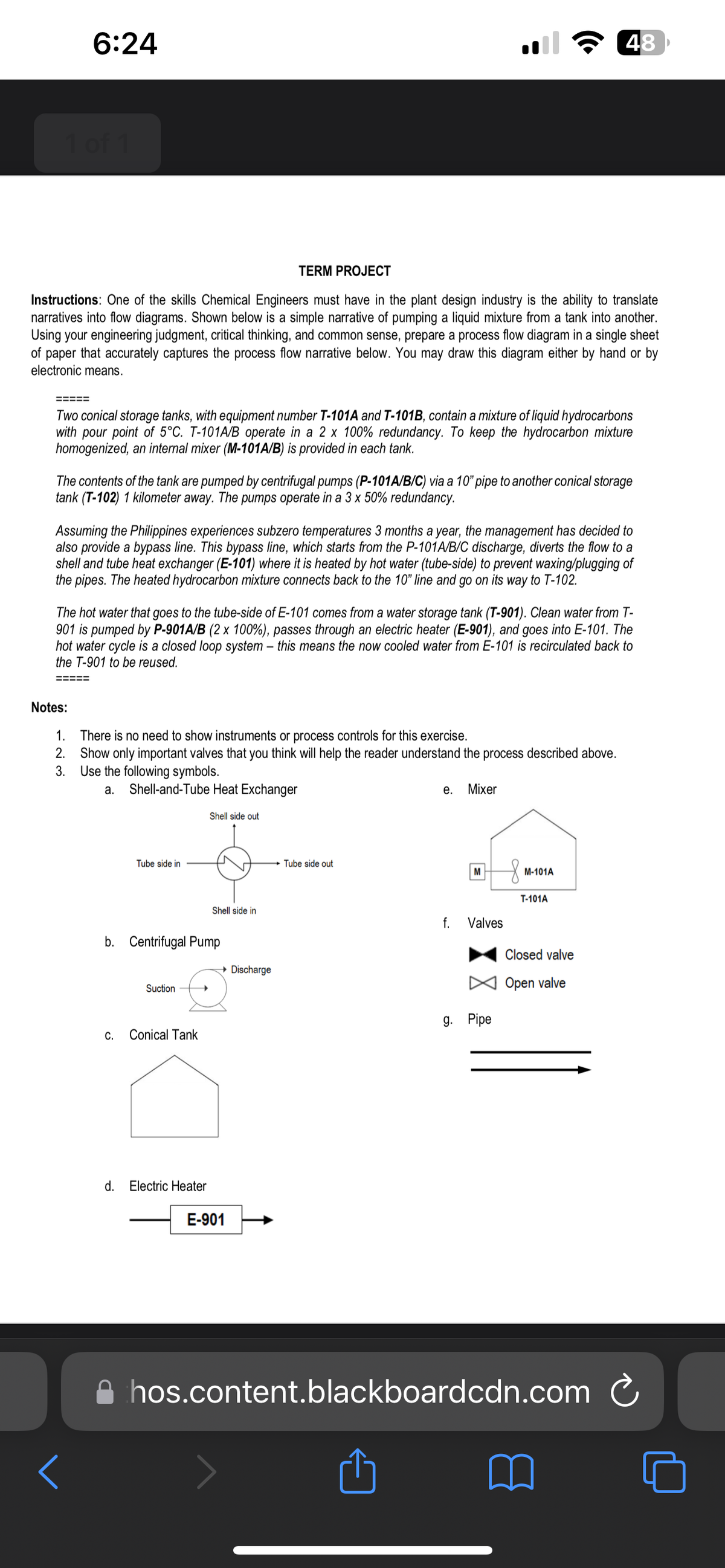

Instructions: One of the skills Chemical Engineers must have in the plant design industry is the ability to translate

narratives into flow diagrams. Shown below is a simple narrative of pumping a liquid mixture from a tank into another.

Using your engineering judgment, critical thinking, and common sense, prepare a process flow diagram in a single sheet

of paper that accurately captures the process flow narrative below. You may draw this diagram either by hand or by

electronic means.

Two conical storage tanks, with equipment number T-101A and T-101B, contain a mixture of liquid hydrocarbons

with pour point of 5°C. T-101A/B operate in a 2 x 100% redundancy. To keep the hydrocarbon mixture

homogenized, an internal mixer (M-101A/B) is provided in each tank.

The contents of the tank are pumped by centrifugal pumps (P-101A/B/C) via a 10" pipe to another conical storage

tank (T-102) 1 kilometer away. The pumps operate in a 3 x 50% redundancy.

Assuming the Philippines experiences subzero temperatures 3 months a year, the management has decided to

also provide a bypass line. This bypass line, which starts from the P-101A/B/C discharge, diverts the flow to a

shell and tube heat exchanger (E-101) where it is heated by hot water (tube-side) to prevent waxing/plugging of

the pipes. The heated hydrocarbon mixture connects back to the 10" line and go on its way to T-102.

The hot water that goes to the tube-side of E-101 comes from a water storage tank (T-901). Clean water from T-

901 is pumped by P-901A/B (2 x 100%), passes through an electric heater (E-901), and goes into E-101. The

hot water cycle is a closed loop system - this means the now cooled water from E-101 is recirculated back to

the T-901 to be reused.

=====

Notes:

1. There is no need to show instruments or process controls for this exercise.

2.

Show only important valves that you think will help the reader understand the process described above.

3. Use the following symbols.

a.

Shell-and-Tube Heat Exchanger

Shell side out

<

Tube side in

b. Centrifugal Pump

Suction

C. Conical Tank

Shell side in

d. Electric Heater

→ Discharge

E-901

Tube side out

e. Mixer

M

f. Valves

48

g. Pipe

M-101A

T-101A

Closed valve

Open valve

hos.content.blackboardcdn.com

Ć

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 3 steps with 1 images

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The