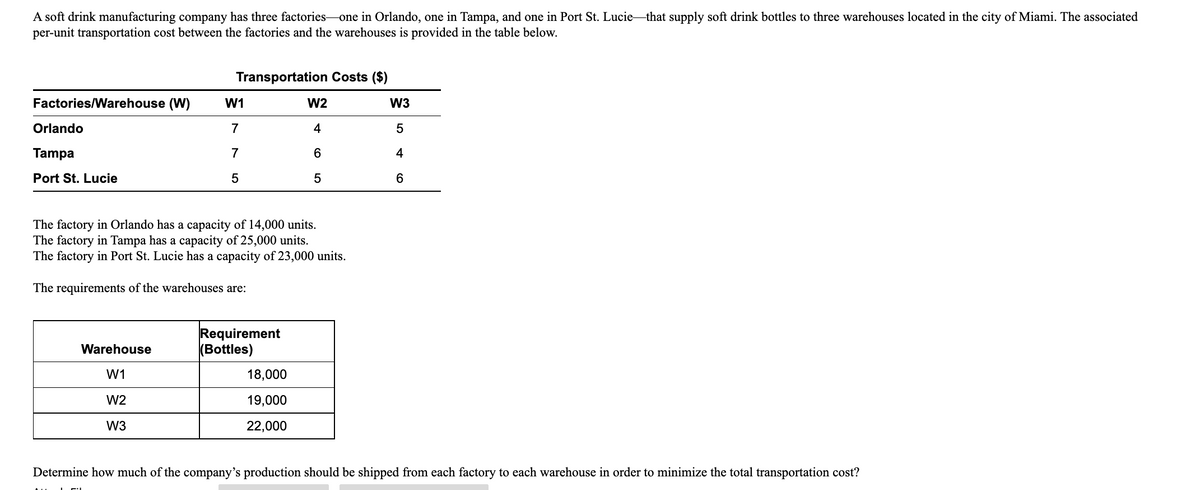

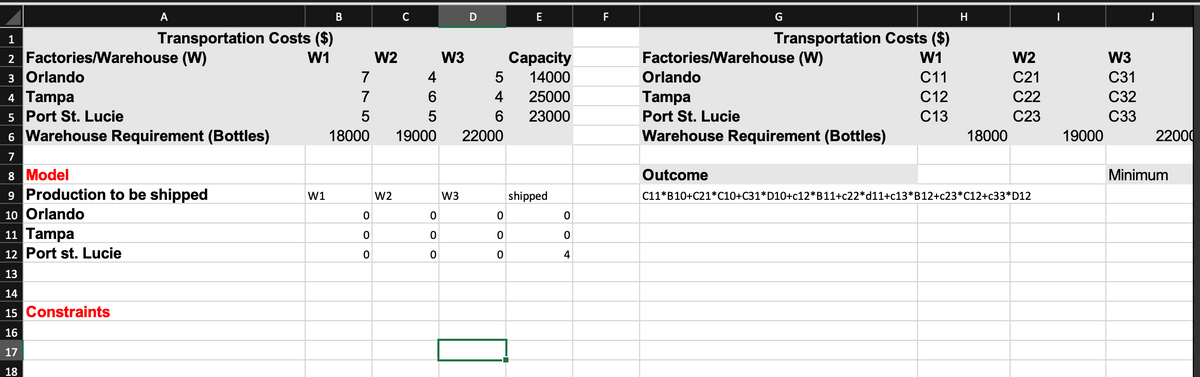

What are the constraints

Q: Using the FCFS rule for scheduling, the sequence is 1-2-3 3-2-1 1-3-2 2-1-3 2-3-1 3-1-2 Sunny Park…

A: FCFS: FCFS stands for First Come and First Serve. As per the FCFS rule, the process…

Q: A copier store has four pieces of automatic equipment, but sometimes they are down because they need…

A: There are four pieces that need maintenance. Hence, this is a finite calling population queue.…

Q: Identify the objectives of Nike

A: Nike Inc. fights against competition while pursuing global market supremacy. Competitive rivalry…

Q: Given the following product structure, master production schedule, and inventory status below and…

A: Given information is Period 8 9 10 11 12 Gross req of A 100 60 160 Gross req of H 90…

Q: Using a 95% confidence level, the upper and lower control limits are: Upper control limit…

A: Formulae used: σp =P -+ (1-P)n For control limit: UCLp =P + Z×σp

Q: Hart Manufacturing makes three products. Each product requires manufacturing operations in three…

A: Objective Functions and Constraints: Based on the given details, the objective…

Q: Develop a minimum makespan schedule using Johnson's rule. The schedule using Johnson's rule is - -…

A: Sequencing is an appropriate order of plan as per which the process of operations works. It defines…

Q: What is the initial total cost of the given transportation model if an Intuitive Approach method is…

A: Given the data stated below, Here, I would apply the intuitive approach method to determine the…

Q: A contractor, Susan Meyer, has to haul gravel to three building sites. She can purchase as much as…

A: Objective functions and constraints: Objective functions: Minimize C = (100+300) X11…

Q: Explain the role of TPS in Supply chain management

A: TPS stands for transaction processing system. This is an information system that is commonly used by…

Q: discuss what a baseline budget is and its relevance using the scenario.

A: In order to set up a baseline budget, it’s important to know what your company can afford to spend…

Q: Discuss solutions to high production Cost

A: A company that produces goods or merchandise is considered a manufacturer. Putting together various…

Q: What is the service rate for the service technician? minutes/unit What is the labor utilization…

A: As per Bartleby guidelines, we can only solve the first three subparts of one question at a…

Q: Product A is an end item and is made from two units of B and four of C. B is made of three units of…

A: Ans) Product Tree:

Q: 2.13 Consider a simple three-step manufacturing process as illustrated in the given figure. Assuming…

A: Given data: Defect rate for Process-1 (d1) = 3% Defect rate for Process-2 (d2) = 5%Defect rate for…

Q: The demand for subassembly S is 100 units in week 7. Each unit of S requires 1 unit of T and 2 units…

A: Product structure- shows the hierarchy-based decomposition of the product, It is generally called…

Q: The Fruits&Nuts Blending Problem Fruits & Nuts produces Yummix, a snack that is a mixture of dried…

A: Let dried fruits composition be a nuts be b cereal be c Objective is to minimize the cost Objective…

Q: The Ace Manufacturing Company has orders for three similar products. Product A B C 1 2 Machine 3 A A…

A: (a)

Q: The Open Science Framework has developed different badges to recognize ethical and transparent…

A: The open science framework (OSF) is a strategic tool used by companies to promote stabilized…

Q: The Dulac Box plant works two 8-hour shifts each day. In the past, 500 cypress packing boxes were…

A: Productivity is analysis of a efficient of company's performance that compare the product and…

Q: What is meant by "Fordism"? explain briefly and give an example.

A: The term "Fordism" refers to a way of economic development and progress where mass production of…

Q: 1. Draw a network diagram representing the project. Put the node numbers in circles and draw arrows…

A: A table consisting of activity names, initial node, final node and estimated duration is given in…

Q: What are the disadvantages of the supply management

A: The act of locating, obtaining, and managing resources, including suppliers, that seem to be crucial…

Q: Brooks Development Corporation (BDC) faces the following capital budgeting decision. Six real estate…

A: Given data is Project 1 2 3 4 5 6 NPV ($ millions) 19 9 17 18 24 13 Expenditure ($ millions)…

Q: , schedule, and control a wide variety of projects. List the four projects according as they appear…

A: In essence, CPM and PERT are project management methodologies that were developed by Western…

Q: Suppose a certain manufacturing company produces connecting rods for 4- and 6-cylinder automobile…

A: Decision variable: Suppose-x4 = the number of 4-cylinder connecting rods produced next week.x6 = the…

Q: A company manufactures x units of Product A and y units of Product B, on two machines, I and II. It…

A: Linear programming is a mathematical technique that is also used in operations management…

Q: The Scottsville Textile Mill produces several different fabrics on eight dobby looms that operate 24…

A: There are 8 dobby looms. Each Dobby loom turns 4.62 yards of fabric per hour. The looms operate 24…

Q: Using samples of 197 credit card statements, an auditor found the following: Sample 1 3 errors…

A: Find the Calculation methods below: Fraction Defectives = Number with Errors Credit Card…

Q: What is meant by bench marking? Explain the benefits a firm derives from benchmarking

A: By comparing your company's success to that of other comparable businesses, you may determine…

Q: Mattress Wholesalers, Inc. is constantly trying to reduce inventory in its supply chain. Last…

A: Given, Last year: COGS = $7.48 million Inventory = $1.48 million This year: COGS = $8.56 million…

Q: Topic: Problems and Concerns in Retail Business Operations These are the concerns of business…

A: Retail business operations are the activities that are directly occurring between the seller and the…

Q: Answer each of the following two problems (1) using regression analysis (easiest way is using the…

A: Given data is

Q: Good Project management software provides features helpful in successfully managing the project.…

A: Project management includes the planning and organizing of the resources related to the task or…

Q: f JIT (Just-In-Time) means both a technical solution to the scheduling task and a managerial…

A: Just-In-Time (JIT) is a manufacturing philosophy that emphasizes the efficient use of manufacturing…

Q: The Economic Order Quantity (EOQ) model is a classical model used for controlling inventory and…

A: Economic order quantity (EOQ) is the optimal quantity that helps in minimizing the total annual cost…

Q: California Gardens, Inc., prewashes, shreds, and distributes a variety of salad mixes in 2-pound…

A: The crossover point is the point at which the total of the fixed and variable costs for any two…

Q: a) How many tires should Rocky Mountain order each time it places an order? Rocky Mountain's optimal…

A: EOQ = √(2DS/H) Annual Holding cost = (Q*H)/2 Annual Setup cost = (D*S)/Q Annual purchase cost =…

Q: Activity A can start as soon as the project starts, and set the earliest start time for activity an…

A: Given: Duration of activity A (D) = 5 Early start of activity A (ES) = 0

Q: Supply chain configuration represents how the participating company members relate to each other to…

A: Companies may usually desire or expect to have complete control over their entire supply chain…

Q: Cycle Time and Velocity, MCE Computador has a manufacturing plant in Des Moines that has the…

A: Theoretical capacity = 182,250 Actual capacity = 72,900 Conversion cost = $7,290,000 Available…

Q: Radovilsky Manufacturing Company, in Hayward, California, makes flashing lights for toys. The…

A: Total anuual cost is the sum of Average holding cost , Average setup cost and purchase cost of the…

Q: You have developed the following simple product structure of items needed for your gift bag for a…

A: Given data: Requirement of end item (J) = 200 (Forecast) units of K= 1 units of L = 5 units of M =…

Q: Briefly describethe bottom of the pyramid (BOP) process for developing business specifications.

A: The phrase "bottom of the pyramid" (BOP), sometimes known as "base of the pyramid," is used in…

Q: Customers arrive at a store randomly, following a Poisson distribution at an average rate of 20 per…

A: The parameter value, meaning average rate of arrivals, lambda, entirely describes the behaviour of…

Q: Disscus the possbile causes of the following production waste 4.1.2 Overproduction waste

A: Overproduction waste is a type of waste that can happen in any organization. It is when the company…

Q: SAMPLE NUMBER 1 -2345678 3 10 11 12 13 14 15 READINGS (IN OHMS) 976 1014 1019 1018 989 1009 995 984…

A: Formulae used: Mean (X) =X1+X2+X3........XnNRange = X (largest value) - X (smallest value) Xbar…

Q: The MRP gross requirements for Item A are shown here for the next 10 weeks. Lead time for A is three…

A: Gross requirements are the entire amount of a good or service required to satisfy customer demand.…

Q: What term is used to describe the checkpoints (Go/No-go decision points) that occur during a project…

A: A project's worth and viability are determined by a go/no-go decision, which decides whether to move…

Q: anges to the Change Authorit on Management Approach

A: The project manager is the person in charge of managing the project. Therefore, a project's driving…

What are the constraints

Trending now

This is a popular solution!

Step by step

Solved in 2 steps

- Scenario 3 Ben Gibson, the purchasing manager at Coastal Products, was reviewing purchasing expenditures for packaging materials with Jeff Joyner. Ben was particularly disturbed about the amount spent on corrugated boxes purchased from Southeastern Corrugated. Ben said, I dont like the salesman from that company. He comes around here acting like he owns the place. He loves to tell us about his fancy car, house, and vacations. It seems to me he must be making too much money off of us! Jeff responded that he heard Southeastern Corrugated was going to ask for a price increase to cover the rising costs of raw material paper stock. Jeff further stated that Southeastern would probably ask for more than what was justified simply from rising paper stock costs. After the meeting, Ben decided he had heard enough. After all, he prided himself on being a results-oriented manager. There was no way he was going to allow that salesman to keep taking advantage of Coastal Products. Ben called Jeff and told him it was time to rebid the corrugated contract before Southeastern came in with a price increase request. Who did Jeff know that might be interested in the business? Jeff replied he had several companies in mind to include in the bidding process. These companies would surely come in at a lower price, partly because they used lower-grade boxes that would probably work well enough in Coastal Products process. Jeff also explained that these suppliers were not serious contenders for the business. Their purpose was to create competition with the bids. Ben told Jeff to make sure that Southeastern was well aware that these new suppliers were bidding on the contract. He also said to make sure the suppliers knew that price was going to be the determining factor in this quote, because he considered corrugated boxes to be a standard industry item. Is Ben Gibson acting legally? Is he acting ethically? Why or why not?Scenario 3 Ben Gibson, the purchasing manager at Coastal Products, was reviewing purchasing expenditures for packaging materials with Jeff Joyner. Ben was particularly disturbed about the amount spent on corrugated boxes purchased from Southeastern Corrugated. Ben said, I dont like the salesman from that company. He comes around here acting like he owns the place. He loves to tell us about his fancy car, house, and vacations. It seems to me he must be making too much money off of us! Jeff responded that he heard Southeastern Corrugated was going to ask for a price increase to cover the rising costs of raw material paper stock. Jeff further stated that Southeastern would probably ask for more than what was justified simply from rising paper stock costs. After the meeting, Ben decided he had heard enough. After all, he prided himself on being a results-oriented manager. There was no way he was going to allow that salesman to keep taking advantage of Coastal Products. Ben called Jeff and told him it was time to rebid the corrugated contract before Southeastern came in with a price increase request. Who did Jeff know that might be interested in the business? Jeff replied he had several companies in mind to include in the bidding process. These companies would surely come in at a lower price, partly because they used lower-grade boxes that would probably work well enough in Coastal Products process. Jeff also explained that these suppliers were not serious contenders for the business. Their purpose was to create competition with the bids. Ben told Jeff to make sure that Southeastern was well aware that these new suppliers were bidding on the contract. He also said to make sure the suppliers knew that price was going to be the determining factor in this quote, because he considered corrugated boxes to be a standard industry item. As the Marketing Manager for Southeastern Corrugated, what would you do upon receiving the request for quotation from Coastal Products?Using the information in Problem (The demand for subassembly Sis 100 units in week 7.Each unit ofS requires 1 unit ofT and 2 units ofU. Each unit ofT requires I unit ofY, 2 units ofW, and 1 unit of X. Finally, eachunit of U requires 2 units of Y and 3 units of Z. One firm manufacturesall items. It takes 2 weeks to make S, 1 week to make T, 2 weeks to make U, 2 weeks to make Y, 3 weeks to make W,I week to make X, 2 weeks to make Y, and I week to make Z.a) Construct a product structure. Identify all levels, parents, and components.b) Prepare a time-phased product structure. ), construct a netmaterial requirements plan using the following on-hand inventory.

- Subj: Business/ Operations Management Scenario: John used the AirBnB platform to book a condo for his staycation with his family on Dec 17 in Cebu, but due to the typhoon Odette, he had to cancel on Dec 16. Because the cancellation was done within 48 hrs, he's no longer eligible for a full refund. He also missed to file a claim within 14 days due to power outage and loss of internet connection caused by the typhoon. 1. Identify the problems with Airbnb’s current refund process. 2. Provide at least three possible solutions and include the pros and cons for each suggested solution then choose the best solution based on your assessment. 3. What are the pros and cons of the current policy versus your proposed solution?Refer again to Problems( Using the information in Problem(The demand for subassembly Sis 100 units in week 7.Each unit ofS requires 1 unit ofT and 2 units ofU. Each unit ofT requires I unit ofY, 2 units ofW, and 1 unit of X. Finally, eachunit of U requires 2 units of Y and 3 units of Z. One firm manufacturesall items. It takes 2 weeks to make S, 1 week to make T, 2 weeks to make U, 2 weeks to make Y, 3 weeks to make W,I week to make X, 2 weeks to make Y, and I week to make Z.a) Construct a product structure. Identify all levels, parents, and components.b) Prepare a time-phased product structure. ), construct agross material requirements plan. ). In addition to100 units of S, there is also a demand for 20 units of U, which isa component of S. The 20 units of U are…Finance Mrs Banks baked some curry puffs. She packed them into boxes of 7 and had 3 curry puffs left. If she had 39 boxes of curry puffs, how many of them did she bake?

- Select one CORRECT OPTION Network Planning in SCM does not impact the following a.Match supply and demand b.SCM Cost c.Optimize resources utilization d.New product launchThe demand for subassembly Sis 100 units in week 7.Each unit ofS requires 1 unit ofT and 2 units ofU. Each unit ofT requires I unit ofY, 2 units ofW, and 1 unit of X. Finally, eachunit of U requires 2 units of Y and 3 units of Z. One firm manufacturesall items. It takes 2 weeks to make S, 1 week to make T, 2 weeks to make U, 2 weeks to make Y, 3 weeks to make W,I week to make X, 2 weeks to make Y, and I week to make Z.a) Construct a product structure. Identify all levels, parents, and components.b) Prepare a time-phased product structure.Suppose that you're a CTO of a company and tasked of building a new warehouse for your Org's systems, answer the following questions in detail and explain why? Tell me about: Location of the warehouse ( State in the US)- where and why? How many systems you will request? Cooling considerations, and why? Expected rough estimate on cost to build and configure the warehouse (land, building cost, system cost, internet, power)?

- Jerusalem Medical Ltd., an Israeli producer of portablekidney dialysis units and other medical products, developsa 4-month aggregate plan. Demand and capacity (in units) areforecast as follows: The cost of producing each dialysis unit is $985 on regular time,$ 1,310 on overtime, and $1,500 on a subcontract. Inventory carryingcost is $100 per unit per month. T here is to be no beginning or endinginventory in stock and back orders are not permitted. Set up a productionplan that minimizes cost using the transportation method.1 to 4 are based on this problem.Jack is considering purchase the following items for his backpacking trip. The cost and the condition of each item are listed in the following table: Item Number Description Condition 1 Backpacking Tarp Not if 3 and only if 2 2 Hammock Not if 3 3 Backpacking Tent Not if 1 or 2 4 Sleeping Bag Must if 5 5 Sleeping Pad Only if 4 Ci is the Cost of item i. Jack needs at least 3 items. Formulate an IP to minimize the total cost. Decision Variables: Xi=1 if item i is purchased; 0 otherwise. Question 1: What are the constraints for item 1? a.) X1+X3<=1; X2-X1<=0 b.) X1-X2-X3<=-1 c.) X1+X3<=1; X1-X2<=0 d.) X1+X3>=1; X1-X2<=0 Question 2: What is the constraint for item 2? a.) X2-X3<=0 b.) X2+X3<=1 c.) X2+X3>=1 d.) X2+X3<=0 Question 3: What is the constraint for item 4? a.) X4+X5>=0 b.) X4-X5>=0 c.) X4-X5<=0 d.) X4+X5<=0 Question 4: Which statement about the formulation is not true? a.) In this…How did you get the total demand as 640 and why is the anwser 46 can you express it algebraicly