What is the level total Production Rate? Answer units (b) What is the maximum quantity subcontracted and in which period? Quantity-Answer and Period-Answer (c) What is the maximum quantity backlogged and in which period? Quantity-Answer and Period-Answer (d) What is the total regular production cost? $Answer (e) What is the total overtime cost? $Answer (f) What is the total subcontracting cost? $Answer (g) What is the total inventory carrying cost? $Answer (h) What is the total backorder cost? $Answer (i) What is the total aggregate plan cost? $Answer

What is the level total Production Rate? Answer units (b) What is the maximum quantity subcontracted and in which period? Quantity-Answer and Period-Answer (c) What is the maximum quantity backlogged and in which period? Quantity-Answer and Period-Answer (d) What is the total regular production cost? $Answer (e) What is the total overtime cost? $Answer (f) What is the total subcontracting cost? $Answer (g) What is the total inventory carrying cost? $Answer (h) What is the total backorder cost? $Answer (i) What is the total aggregate plan cost? $Answer

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter12: Queueing Models

Section: Chapter Questions

Problem 59P

Related questions

Question

What is the level total Production Rate? Answer units

(b) What is the maximum quantity subcontracted and in which period? Quantity-Answer and Period-Answer

(c) What is the maximum quantity backlogged and in which period? Quantity-Answer and Period-Answer

(d) What is the total regular production cost? $Answer

(e) What is the total overtime cost? $Answer

(f) What is the total subcontracting cost? $Answer

(g) What is the total inventory carrying cost? $Answer

(h) What is the total backorder cost? $Answer

(i) What is the total aggregate plan cost? $Answer

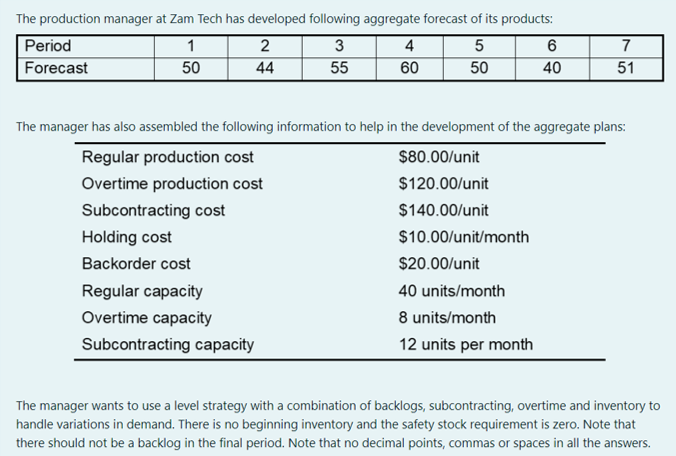

Transcribed Image Text:The production manager at Zam Tech has developed following aggregate forecast of its products:

Period

Forecast

3

55

5

50

2

4

6

7

50

44

60

51

40

The manager has also assembled the following information to help in the development of the aggregate plans:

Regular production cost

$80.00/unit

Overtime production cost

$120.00/unit

Subcontracting cost

$140.00/unit

Holding cost

$10.00/unit/month

Backorder cost

$20.00/unit

Regular capacity

40 units/month

Overtime capacity

8 units/month

Subcontracting capacity

12 units per month

The manager wants to use a level strategy with a combination of backlogs, subcontracting, overtime and inventory to

handle variations in demand. There is no beginning inventory and the safety stock requirement is zero. Note that

there should not be a backlog in the final period. Note that no decimal points, commas or spaces in all the answers.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps with 2 images

Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning