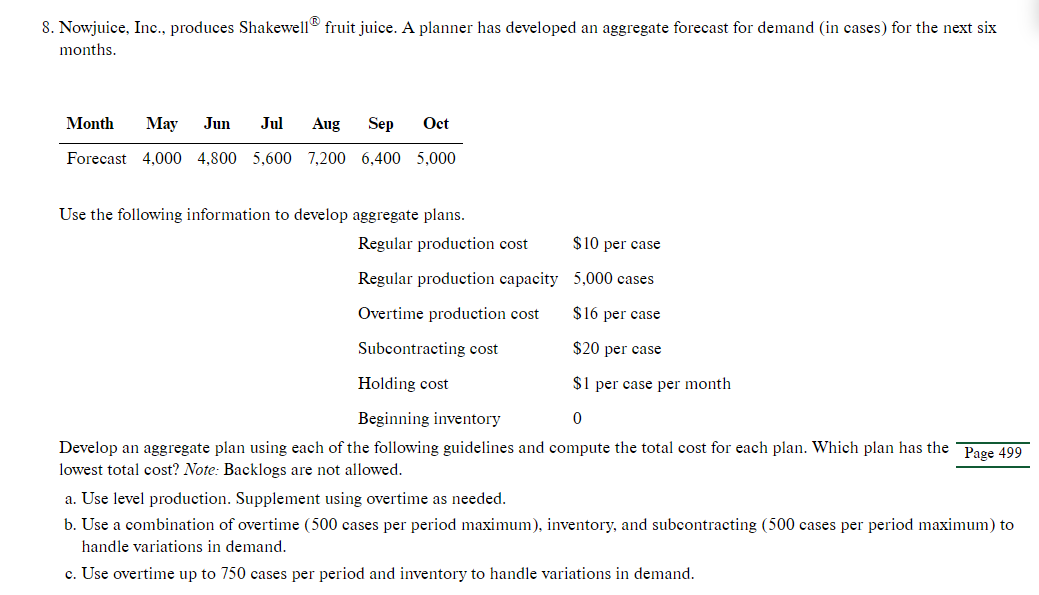

. Nowjuice, Inc., produces Shakewell® fruit juice. A planner has developed an aggregate forecast for demand (in cases) for the next six months.

Q: A forecast of 240 units in January, 320 units in February, and 240 units in March has been approved…

A: January Forecast = 240 February Forecast = 320 Product C Forecast = 240*0.25 = 60 in January and…

Q: How does aggregate planning in service differ fromaggregate planning in manufacturing?

A: Manufacturing refers to the production of products for either use or for sale, by using labor and…

Q: Level Capacity Production Plan Problem o Manager T. C. Downs of Plum Engines, a producer of lawn…

A: Find the given Details below: Month 1 2 3 4 5 6 7 8 Total Forecast 120 135 140 120 125 125 140…

Q: Tabard Industries forecasted the following demand for one of its most profitable products for the…

A:

Q: a) For an upcoming red carpet evening, a company is selling tickets at $60 per person at a large…

A:

Q: Jerusalem Medical Ltd., an Israeli producer of portable kidney dialysis units and other medical…

A: Cost of producing each unit on regular time = $985 Overtime = $1310 and Subcontract = $1600

Q: Prepare a Master Production Schedule (MPS) for an Agri-Chemical company given the following…

A: First calculate the projected-on hand inventory for each period using the following formula.…

Q: Identify the intermediate plan given in the scenario.

A: Planning : Planning helps the managers to decide things in advance about what is to be done and how…

Q: . Manager T. C. Downs of Plum Engines, a producer of lawn mowers and leaf blowers, must developan…

A: Formula: Answer: The total cost of the plan is $62,850.

Q: A production line is to run at 1000 units per month. Sales are forecast as shown in the following.…

A: Given data is

Q: The Aggies will host Tech in this year’s homecomingfootball game. Based on advance ticket sales, the…

A: The given data is as follows : Sales Quantity Probability 2000 0.10 3000 0.30 4000 0.30…

Q: The production manager at Zam Tech has developed following aggregate forecast of its products: The…

A: For a level plan the production level is kept constant. Here, since the cost of reuglar production…

Q: Manager T. C. Downs of Plum Engines, a producer of lawn mowers and leaf blowers, must develop an…

A: A chase plan refers to a plan in which the production level is matched the market demand of the…

Q: The forecasted requirements for an electric hand drill for the next 6 weeks are 15, 40, 10, 20, 50,…

A: Find the Calculation methods below: Requirement = (Maximum value of Demand and Customer order)Net…

Q: A forecast of 320 units in January, 400 units in February,and 240 units in March has been approved…

A:

Q: F Precision Building Cost Forecast by City S70,000 S60,000 Cost Forecasts by City - Kitchens 2…

A: Given data is

Q: Task 2: A small Tennessee company makes fused magnesia and silica. To prepare input for the planning…

A: Given data is Production quantity = 40000 pounds Safety stock = 30000 pounds

Q: Using the accompanying log-log graph, answer the following questions: What are the implications for…

A: Management includes a different set of principles planning, directing, organizing, and controlling…

Q: Application of sostac planning framework to the Bradford 2025 intiative.

A: Ans. Liverpool won the European Capital of Culture title in 2008. This was an Europe-wide contest to…

Q: Jerusalem Medical Ltd., an Israeli producer of portable kidney dialysis units and other medical…

A: Given data,

Q: Medical Ltd., an Israeli producer of portable kidney dialysis units and other medical products,…

A:

Q: Prepare a Master Schedule like that shown in Figure 11.11 given the following information: The…

A: MPS ordering rule is to be used here. The calculations are shown below: Week Prev week inv Req…

Q: A manager is attempting to put together an aggregate production plan for the coming nine months. She…

A: an aggregate plan using the information given- With 20 permanent workers initially with each…

Q: Problem #1: Extension of the solved problem in the class The washing machine plant is interested in…

A: Given data is Starting inventory = 200 units Production in 40 days = 520 units Workers in 40 days =…

Q: Snip

A: Given Data: Let, B =beginning inventory E = ending inventory D = demand for the month P = production…

Q: Compute a 3-months moving average for the period from r

A: A three month moving average is a forecasting method which identifying the average of previous three…

Q: The planner at a company that makes garden tractors is about to prepare an aggregate production plan…

A: Disclaimer-Since you have asked multiple question we will solve the first question for you. If you…

Q: Prepare a master schedule given this information: The forecast for each week of an eight-week…

A:

Q: Northwest Pipe (NP) makes water pipe. NP is planningproduction for the next seven months, March…

A: given, Th e forecast demands (in thousands of feet) are, respectively, 40,60, 70, 80, 90, 100, and…

Q: A company evaluate its hiring cost is RM150 per worker and layoff cost is RM200 per worker.…

A: Given data is Hiring cost = RM150 Layoff cost = RM200 Current number of workers = 20 Forecasted…

Q: erusalem Medical Ltd., an Israeli producer of portable kidney dialysis units and other medical…

A: To calculate Supply (month), the formula would be Regular time units +Overtime units +Subcontract…

Q: Crystal Clear Health Drinks: A health drink production company, Crystal Clear Health Drinks,…

A: Since you have submitted multiple questions, as per guidelines we have answered the first question…

Q: What is CAPACITY REQUIREMENTS FORECASTING?

A: It is the forecasting method where a company tries to forecast the production limit in the future to…

Q: Spring and Summer Fashions, a clothing producer, has generated a forecast for the next eight…

A: The steady production of 1,200 units is maintained. As the production rate per worker is not given,…

Q: An aggregate plan is to be developed for the forecast of demand covering nine periods shown in Table…

A: Aggregate planning is a process for creating a long-term manufacturing strategy that assures a…

Q: Edwards and Bell market a single line of home computers, dubbed the XL-98. The master budget forthe…

A: Hence, the total static budget variance in operating profit is $20,000.

Q: A company is in the process of preparing a budget for launching a new product. The following table…

A: A project network diagram is a graphic depiction of a project's process. A network diagram is a…

Q: Is it possible to use the exponential smoothing method? What is it like?

A: Forecasting is a mathematical tool for making decisions, predictions, and scheduling processes for…

Q: How does trend line improve production?

A: Production is described as the process or approach of economic resources or input like land,…

Q: A phone production company must prepare the production planning for the next 9 weeks. Complete the…

A: Gross requirements: It is the total requirement of a particular product. Receipt: It is the placed…

Q: Understand the importance of operation management in organization. Define errors in forecast to make…

A: Project management is a list of a project activities and deliverables, usually with a start and…

Q: What are demand forecasting and capacity strategy? Give an example of demand forecasting for a…

A: A company's decision-making is heavily influenced by demand. In a competitive industry, it is…

Q: 1. Develop an aggregate plan for the following forecast 3 4 5 6 7 8 9 Total Period 1 2 Forecast 190…

A: Total worker = 20 Production = 10 unit per period Cost= P6.00 per unit. Inventory Carrying cost =…

Q: Explain the weighted moving average method?

A: Weighted moving average method of forecasting: This method gives the forecast while assigning…

Q: • Manager T. C. Downs of Plum Engines, a producer of lawn mowers and leaf blowers, must develop an…

A: Forecasting is the activity of making estimated valuations of future activities based on past and…

Can you show me how to work this in excel

Trending now

This is a popular solution!

Step by step

Solved in 3 steps with 3 images

- . Manager T. C. Downs of Plum Engines, a producer of lawn mowers and leaf blowers, must developan aggregate plan given the forecast for engine demand shown in the table. The department has aregular output capacity of 130 engines per month. Regular output has a cost of $60 per engine. Thebeginning inventory is zero engines. Overtime has a cost of $90 per engine.a. Develop a chase plan that matches the forecast and compute the total cost of your plan. Regularproduction can be less than regular capacity. b. Compare the costs to a level plan that uses inventory to absorb fluctuations. Inventory carryingcost is $2 per engine per month. Backlog cost is $90 per engine per month. There should not bea backlog in the last month.MONTH1 2 3 4 5 6 7 8 TotalForecast 120 135 140 120 125 125 140 135 1,040A forecast of 320 units in January, 400 units in February,and 240 units in March has been approved for the seismic-sensory product family manufactured at the Rockport facilityof Maryland Automated, Inc. Three products, A, B, and C,comprise this family. The product mix ratio for products A,B, and C for the past 2 years has been 35 percent, 40 percent,and 25 percent, respectively. Management believes that themonthly forecast requirements are evenly spread over the4 weeks of each month. Currently, 15 units of product C areon hand. The company produces product C in lots of 40, andthe lead time is 2 weeks. A production quantity of 40 unitsfrom the previous period is scheduled to arrive in week 1. Thecompany has accepted orders of 25, 9, 11, 5, 4, and 9 unitsof product C in weeks 1 through 6, respectively. Prepare aprospective MPS for product C and calculate the available-to-promise inventory quantitiesManager T. C. Downs of Plum Engines, a producer of lawn mowers and leaf blowers, must develop an aggregate plan given the forecast for engine demand shown in the table. The department has a regular output capacity of 135 engines per month. Regular output has a cost of $60 per engine. The beginning inventory is zero engines. Overtime has a cost of $100 per engine. a. Develop a chase plan that matches the forecast and compute the total cost of your plan. Regular production can be less than regular capacity. (Negative amounts should be indicated by a minus sign. Leave no cells blank - be certain to enter "0" wherever required.) b. Compare the costs to a level plan that uses inventory to absorb fluctuations. Inventory carrying cost is $2 per engine per month. Backlog cost is $120 per engine per month. There should not be a backlog in the last month. Set regular production equal to the monthly average of total forecasted demand. Assume that using overtime is not an option. (Negative amounts…

- Sales for Pandora’s Jewellery for the past three months have been 200,350, and 287. Usea three-month moving average to calculate a forecast for the fourth month. If the actual demandfor month 4 turns out to be 300, calculate the forecast for month 5.Problem 11-11 (Static) A manager is attempting to put together an aggregate plan for the coming nine months. She has obtained a forecast of expected demand for the planning horizon. The plan must deal with highly seasonal demand; demand is relatively high in periods 3 and 4, and again in period 8, as can be seen from the following forecasts. Period 1 2 3 4 5 6 7 8 9 Total Forecast 190 230 260 280 210 170 160 260 180 1,940 The department now has 20 full-time employees, each of whom produces 10 units of output per period at a cost of $6 per unit. Beginning inventory for period 1 is zero. Inventory carrying cost is $5 per unit per period, and backlog cost is $10 per unit per period. The manager has decided to use part-time workers to assist during seasonal peaks. The cost per unit, including hiring and training, is $11. The output rate is 10 units per worker per period for all workers. A maximum of 10 part-time workers can be used, and the same number of part-time workers…Deb Bishop Health and Beauty Products has developeda new shampoo, and you need to develop its aggregate schedule.The cost accounting department bas supplied you the costsrelevant to the aggregate plan, and the marketing department hasprovided a four-quarter forecast. All are shown as follows: Your job is to develop an aggregate plan for the next four quarters.a) First, try hiring and layoffs (to meet the forecast) as necessary.b) Then try a plan that holds employment steady.c) Which is the more economical plan for Deb Bishop Healthand Beauty Products?

- A manager is attempting to put together an aggregate production plan for the coming nine months. She has obtained forecasts of aggregate demand for the planning horizon. The plan must deal with highly seasonal demand; demand is relatively high in months 3 and 4, and again in month 8, as can be seen below: The company has 20 permanent employees, each of whom can produce 10 units of output per month at a cost of $6 per unit. Inventory holding cost is $5 per unit per month, and back-order cost is $10 per unit per month. The manager is considering a plan that would involve hiring two people to start working in month 1, one on a temporary basis who would work until the end of month 5. The hiring of these two would cost $500. Beginning inventory is 0.Start with 20 permanent workers. Prepare a minimum cost plan that may use some combination of hiring ($250 per worker), subcontracting ($8 per unit, maximum of 20 units per month, must use for at least three consecutive months), and overtime…Southeast Soda Pop, Inc., has a new fruit drink forwhich it has high hopes. John Mitten thai, the production planner,has assembled the fo llowing cost data and demand forecast: John's job is to develop an aggregate plan. The three initialoptions he wants to evaluate are:• Plan A: a strategy that hires and fires personnel as necessaryto meet the forecast.• Plan B: a level strategy.• Plan C: a level strategy that produces 1,200 cases per quarterand meets the fo recast demand with inventory and subcontracting.a) Which strategy is the lowest-cost plan?b) If you are John's boss, the VP for operations, which p lan doyou implement and why?A forecast of 240 units in January, 320 units in February, and 240 units in March has been approved for the seismic-sensory product family manufactured at the Rockport facility of Maryland Automated, Inc. Three products, A, B, and C, comprise this family. The product mix ratio for products A, B, and C for the past 2 years has been 35 percent, 40 percent,and 25 percent, respectively. Management believes that the monthly forecast requirements are evenly spread over the 4 weeks of each month. Currently, 10 units of product C are on hand. The company produces product C in lots of 40, and the lead time is 2 weeks. A production quantity of 40 units from the previous period is scheduled to arrive in week 1. Thecompany has accepted orders of 25, 12, 8, 10, 2, and 3 units of product C in weeks 1 through 6, respectively. Prepare a prospective MPS for product C and calculate the availableto-promise inventory quantities.

- Develop a chase aggregate plan for Draper using apermanent workforce of 12 employees supplemented by overtime.All demand must be met each period.(a) Show what would happen if this plan were implemented.(b) Calculate the costs associated with this plan.(c) Evaluate the plan in terms of cost, customer service,operations, and human resources.Assume an initial starting Ft of 200 units, a trend (Tt ) of 8 units, an alpha of 0.30, and a delta of 0.40. If actual demand turned out to be 288, calculate the forecast including trend for the next period.Capacity planning requires a demand forecast for an extended period of time into thefuture. What concerns would you have regarding an extended forecast as a capacityplanner?