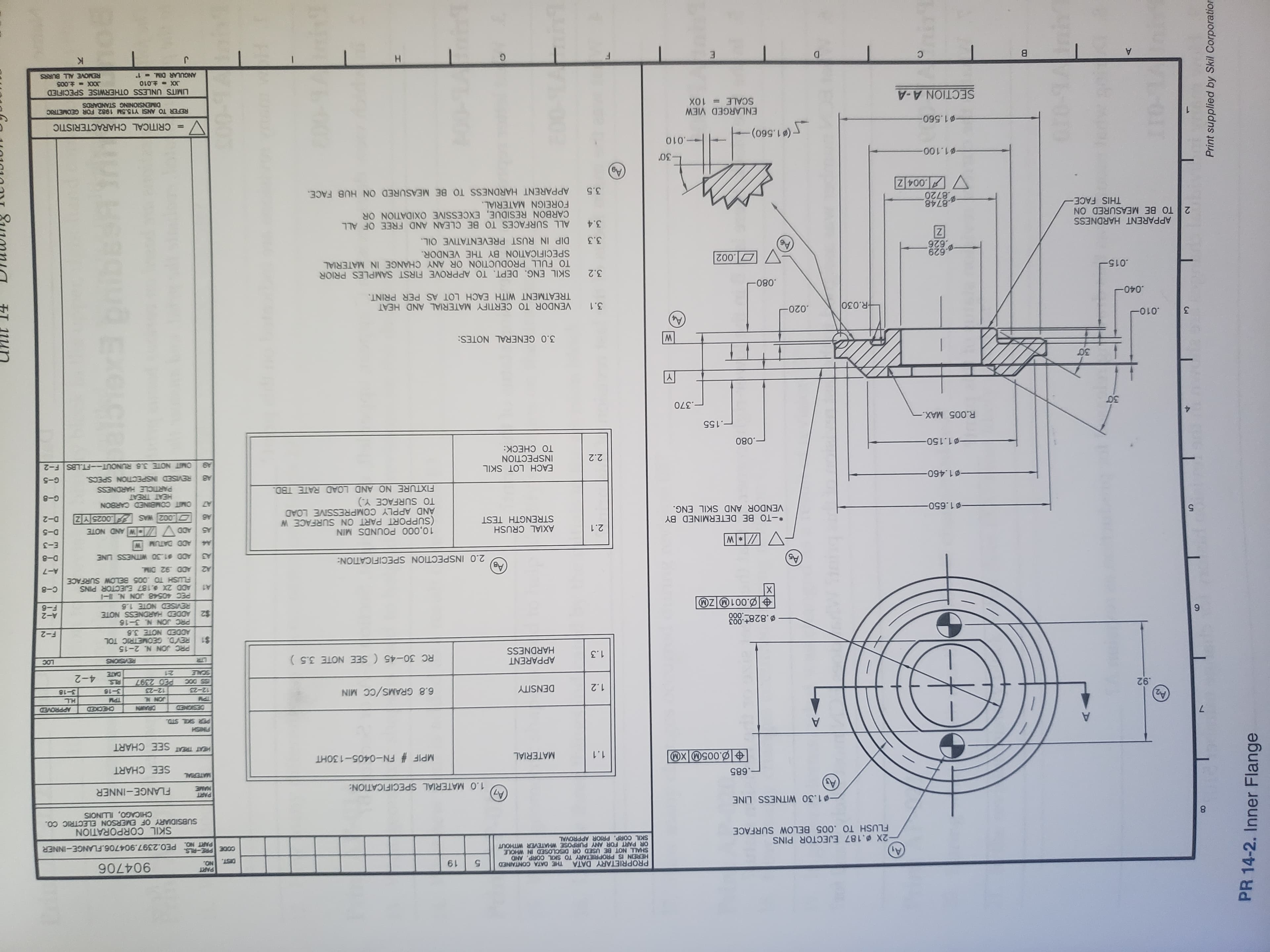

030 Print Reading for Industry Class Date Name Industry Print Exercise 14-2 Refer to the print PR 14-2 and answer the questions below. 1. What are the three columns of the revision history block of this drawing? 2. What revision letter/item number is assigned to the addition of datum W? used to be. 3. Revision A9 is floating next to an empty space where Revision A6 added a triangle and a feature control frame. What does the triangle mean? 5. What revision letter and item number is assigned to the material specification? 6. In what zone is revision A2 located? 7. What type of pin is referred to in revision A1? 8. What change was made in revision A8? Review questions based on previous units: 9. What is the name of this part? 10. How many general notes are shown on this print? 11. If not specified, what is the tolerance for a three-place decimal value? 12. Are there any surface texture symbols shown? 13. What is the maximum material condition diameter of the main central hole? 14. At what scale is the enlarged view? 15. What four geometric tolerances are invoked on this drawing? PROPRIETARY DATA HEREIN IS PROPRIETARY TO SKIL CORP. AND SHALL NOT BE USED OR DISCLOSED IN WHOLE OR PART FOR ANY PURPOSE WHATEVER WITHOUT SKIL CORP. PRIOR APPROVAL PART THE DATA CONTAINED ON PRE-RLS DIST 619 -2X.187 EJECTOR PINS FLUSH TO .005 BELOW SURFACE 3000 PART NO. PEO.2397.904706.FLANGE-INNER SKIL CORPORATION SUBSIDIARY OF EMERSON ELECTRIC CO. CHICAGO, ILLINOIS 1.30 WITNESS LINE PART MAME FLANGE-INNER 1.0 MATERIAL SPECIFICATION: .685 MATERIAL SEE CHART .005 XM MPIF # FN-0405-130HT MATERIAL 1.1 HEAT TREAT SEE CHART A A HSN PER SKL SID CENDS DRAWN APPROVED H.L 6.8 GRAMS/CC MIN 92 DENSITY NNO 1.2 12-23 PED 2397 3-16 3-18 12-23 RLS. 4-2 SCALE 21 APPARENT HARDNESS RC 30-45 (SEE NOTE 3.5) REVISIONS 1.3 PRC JON N 2-15 REVD. GEOMETRIC TOL ADDED NOTE 3.6 $1 F-2 D.828+.003 000 .001 MZM PRC JON N. 3-16 $2 ADDED HARDNESS NOTE A-2 REVISED NOTE 1.8 PEC 40548 JON N. ADD 2x .187 EJECTOR PINS 9-3 X A1 FLUSH TO .005 BELOW SURFACE C-8 BV 2.0 INSPECTION SPECIFICATION: ADD 92 DIM A-7 ADD $1.30 WITNESS LINE D-8 ADD DATUM W E-3 10,000 POUNDS MIN (SUPPORT PART ON SURFACE W AND APPLY COMPRESSIVE LOAD TO SURFACE Y.) AXIAL CRUSH STRENGTH TEST 2.1 D-5 A5 *-TO BE DETERMINED BY VENDOR AND SKIL ENG. O002 WAS 0025 YZ D-2 1.650- HEAT TREAT PARTICLE HARDNESS REVISED INSPECTION SPECS. G-8 FIXTURE NO AND LOAD RATE TBD -01.460- G-5 AB EACH LOT SKIL INSPECTION OMIT NOTE 3.6 RUNOUT-FT.LBS F-2 2.2 TO CHECK: 1.150- .080 -.155 R.005 MAX.- .370 30 3.0 GENERAL NOTES: 010- .020 R.030 3.1 VENDOR TO CERTIFY MATERIAL AND HEAT TREATMENT WITH EACH LOT AS PER PRINT. 040- 080 3.2 SKIL ENG. DEPT. TO APPROVE FIRST SAMPLES PRIOR 015- TO FULL PRODUCTION OR ANY CHANGE IN MATERIAL SPECIFICATION BY THE VENDOR. .002 629 .626 3.3 DIP IN RUST PREVENTATIVE OIL APPARENT HARDNESS 2 TO BE MEASURED ON THIS FACE 3.4 ALL SURFACES TO BE CLEAN AND FREE OF ALL CARBON RESIDUE, EXCESSIVE OXIDATION OR FOREIGN MATERIAL .8748 8720 3.5 APPARENT HARDNESS TO BE MEASURED ON HUB FACE. 1.100- -,010 1.560) 1.560- = CRITICAL CHARACTERISTIC ENLARGED VIEW SCALE= 10X REFER TO ANSI Y15.5M 1982 FOR GEOMETRIC DIMENSIONING STANDARDS SECTION A-A LIMITS UNLESS OTHERWISE SPECIFIED X-.010 XXX-.005 REMOVE ALL BURRS ANGULAR DIM.-1 K H 9 2 * 2 2 007 Print supplied by Skil Corporatior PR 14-2. Inner Flange

030 Print Reading for Industry Class Date Name Industry Print Exercise 14-2 Refer to the print PR 14-2 and answer the questions below. 1. What are the three columns of the revision history block of this drawing? 2. What revision letter/item number is assigned to the addition of datum W? used to be. 3. Revision A9 is floating next to an empty space where Revision A6 added a triangle and a feature control frame. What does the triangle mean? 5. What revision letter and item number is assigned to the material specification? 6. In what zone is revision A2 located? 7. What type of pin is referred to in revision A1? 8. What change was made in revision A8? Review questions based on previous units: 9. What is the name of this part? 10. How many general notes are shown on this print? 11. If not specified, what is the tolerance for a three-place decimal value? 12. Are there any surface texture symbols shown? 13. What is the maximum material condition diameter of the main central hole? 14. At what scale is the enlarged view? 15. What four geometric tolerances are invoked on this drawing? PROPRIETARY DATA HEREIN IS PROPRIETARY TO SKIL CORP. AND SHALL NOT BE USED OR DISCLOSED IN WHOLE OR PART FOR ANY PURPOSE WHATEVER WITHOUT SKIL CORP. PRIOR APPROVAL PART THE DATA CONTAINED ON PRE-RLS DIST 619 -2X.187 EJECTOR PINS FLUSH TO .005 BELOW SURFACE 3000 PART NO. PEO.2397.904706.FLANGE-INNER SKIL CORPORATION SUBSIDIARY OF EMERSON ELECTRIC CO. CHICAGO, ILLINOIS 1.30 WITNESS LINE PART MAME FLANGE-INNER 1.0 MATERIAL SPECIFICATION: .685 MATERIAL SEE CHART .005 XM MPIF # FN-0405-130HT MATERIAL 1.1 HEAT TREAT SEE CHART A A HSN PER SKL SID CENDS DRAWN APPROVED H.L 6.8 GRAMS/CC MIN 92 DENSITY NNO 1.2 12-23 PED 2397 3-16 3-18 12-23 RLS. 4-2 SCALE 21 APPARENT HARDNESS RC 30-45 (SEE NOTE 3.5) REVISIONS 1.3 PRC JON N 2-15 REVD. GEOMETRIC TOL ADDED NOTE 3.6 $1 F-2 D.828+.003 000 .001 MZM PRC JON N. 3-16 $2 ADDED HARDNESS NOTE A-2 REVISED NOTE 1.8 PEC 40548 JON N. ADD 2x .187 EJECTOR PINS 9-3 X A1 FLUSH TO .005 BELOW SURFACE C-8 BV 2.0 INSPECTION SPECIFICATION: ADD 92 DIM A-7 ADD $1.30 WITNESS LINE D-8 ADD DATUM W E-3 10,000 POUNDS MIN (SUPPORT PART ON SURFACE W AND APPLY COMPRESSIVE LOAD TO SURFACE Y.) AXIAL CRUSH STRENGTH TEST 2.1 D-5 A5 *-TO BE DETERMINED BY VENDOR AND SKIL ENG. O002 WAS 0025 YZ D-2 1.650- HEAT TREAT PARTICLE HARDNESS REVISED INSPECTION SPECS. G-8 FIXTURE NO AND LOAD RATE TBD -01.460- G-5 AB EACH LOT SKIL INSPECTION OMIT NOTE 3.6 RUNOUT-FT.LBS F-2 2.2 TO CHECK: 1.150- .080 -.155 R.005 MAX.- .370 30 3.0 GENERAL NOTES: 010- .020 R.030 3.1 VENDOR TO CERTIFY MATERIAL AND HEAT TREATMENT WITH EACH LOT AS PER PRINT. 040- 080 3.2 SKIL ENG. DEPT. TO APPROVE FIRST SAMPLES PRIOR 015- TO FULL PRODUCTION OR ANY CHANGE IN MATERIAL SPECIFICATION BY THE VENDOR. .002 629 .626 3.3 DIP IN RUST PREVENTATIVE OIL APPARENT HARDNESS 2 TO BE MEASURED ON THIS FACE 3.4 ALL SURFACES TO BE CLEAN AND FREE OF ALL CARBON RESIDUE, EXCESSIVE OXIDATION OR FOREIGN MATERIAL .8748 8720 3.5 APPARENT HARDNESS TO BE MEASURED ON HUB FACE. 1.100- -,010 1.560) 1.560- = CRITICAL CHARACTERISTIC ENLARGED VIEW SCALE= 10X REFER TO ANSI Y15.5M 1982 FOR GEOMETRIC DIMENSIONING STANDARDS SECTION A-A LIMITS UNLESS OTHERWISE SPECIFIED X-.010 XXX-.005 REMOVE ALL BURRS ANGULAR DIM.-1 K H 9 2 * 2 2 007 Print supplied by Skil Corporatior PR 14-2. Inner Flange

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

I need answers for questions 4, 5, and 6 pertaining to the print provided.

Transcribed Image Text:030

Print Reading for Industry

Class

Date

Name

Industry Print Exercise 14-2

Refer to the print PR 14-2 and answer the questions below.

1. What are the three columns of the revision history block of this drawing?

2. What revision letter/item number is assigned to the addition of datum W?

used to be.

3. Revision A9 is floating next to an empty space where

Revision A6 added a triangle and a feature control frame. What does the triangle mean?

5. What revision letter and item number is assigned to the material specification?

6. In what zone is revision A2 located?

7. What type of pin is referred to in revision A1?

8. What change was made in revision A8?

Review questions based on previous units:

9. What is the name of this

part?

10. How many general notes are shown on this print?

11. If not specified, what is the tolerance for a three-place decimal value?

12. Are there

any surface texture symbols shown?

13. What is the maximum material condition diameter of the main central hole?

14. At what scale is the enlarged view?

15. What four geometric tolerances are invoked on this drawing?

Transcribed Image Text:PROPRIETARY DATA

HEREIN IS PROPRIETARY TO SKIL CORP. AND

SHALL NOT BE USED OR DISCLOSED IN WHOLE

OR PART FOR ANY PURPOSE WHATEVER WITHOUT

SKIL CORP. PRIOR APPROVAL

PART

THE DATA CONTAINED

ON

PRE-RLS

DIST

619

-2X.187 EJECTOR PINS

FLUSH TO .005 BELOW SURFACE

3000

PART NO. PEO.2397.904706.FLANGE-INNER

SKIL CORPORATION

SUBSIDIARY OF EMERSON ELECTRIC CO.

CHICAGO, ILLINOIS

1.30 WITNESS LINE

PART

MAME

FLANGE-INNER

1.0 MATERIAL SPECIFICATION:

.685

MATERIAL

SEE CHART

.005 XM

MPIF # FN-0405-130HT

MATERIAL

1.1

HEAT TREAT SEE CHART

A

A

HSN

PER SKL SID

CENDS

DRAWN

APPROVED

H.L

6.8 GRAMS/CC MIN

92

DENSITY

NNO

1.2

12-23

PED 2397

3-16

3-18

12-23

RLS.

4-2

SCALE

21

APPARENT

HARDNESS

RC 30-45 (SEE NOTE 3.5)

REVISIONS

1.3

PRC JON N 2-15

REVD. GEOMETRIC TOL

ADDED NOTE 3.6

$1

F-2

D.828+.003

000

.001 MZM

PRC JON N. 3-16

$2

ADDED HARDNESS NOTE

A-2

REVISED NOTE 1.8

PEC 40548 JON N.

ADD 2x .187 EJECTOR PINS

9-3

X

A1

FLUSH TO .005 BELOW SURFACE

C-8

BV

2.0 INSPECTION SPECIFICATION:

ADD 92 DIM

A-7

ADD $1.30 WITNESS LINE

D-8

ADD DATUM W

E-3

10,000 POUNDS MIN

(SUPPORT PART ON SURFACE W

AND APPLY COMPRESSIVE LOAD

TO SURFACE Y.)

AXIAL CRUSH

STRENGTH TEST

2.1

D-5

A5

*-TO BE DETERMINED BY

VENDOR AND SKIL ENG.

O002 WAS

0025 YZ

D-2

1.650-

HEAT TREAT

PARTICLE HARDNESS

REVISED INSPECTION SPECS.

G-8

FIXTURE NO AND LOAD RATE TBD

-01.460-

G-5

AB

EACH LOT SKIL

INSPECTION

OMIT NOTE 3.6 RUNOUT-FT.LBS F-2

2.2

TO CHECK:

1.150-

.080

-.155

R.005 MAX.-

.370

30

3.0 GENERAL NOTES:

010-

.020

R.030

3.1

VENDOR TO CERTIFY MATERIAL AND HEAT

TREATMENT WITH EACH LOT AS PER PRINT.

040-

080

3.2 SKIL ENG. DEPT. TO APPROVE FIRST SAMPLES PRIOR

015-

TO FULL PRODUCTION OR ANY CHANGE IN MATERIAL

SPECIFICATION BY THE VENDOR.

.002

629

.626

3.3 DIP IN RUST PREVENTATIVE OIL

APPARENT HARDNESS

2 TO BE MEASURED ON

THIS FACE

3.4 ALL SURFACES TO BE CLEAN AND FREE OF ALL

CARBON RESIDUE, EXCESSIVE OXIDATION OR

FOREIGN MATERIAL

.8748

8720

3.5 APPARENT HARDNESS TO BE MEASURED ON HUB FACE.

1.100-

-,010

1.560)

1.560-

= CRITICAL CHARACTERISTIC

ENLARGED VIEW

SCALE= 10X

REFER TO ANSI Y15.5M 1982 FOR GEOMETRIC

DIMENSIONING STANDARDS

SECTION A-A

LIMITS UNLESS OTHERWISE SPECIFIED

X-.010

XXX-.005

REMOVE ALL BURRS

ANGULAR DIM.-1

K

H

9 2 * 2 2

007

Print supplied by Skil Corporatior

PR 14-2. Inner Flange

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Step 1

VIEWTrending now

This is a popular solution!

Step by step

Solved in 1 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY