1. The appropriate punch size for a blanking operation using to perform a cold-rolled steel (half hard) circular part with diameter 75.0 mm and 2.0 mm thick is: (a) Punch diameter 77.72 mm and Die diameter = 74.50 mm. (b) Punch diameter = 73.50 mm and Die diameter 75.50 mm. %3D (c) Punch diameter 74.70 mm and Die diameter 75.0 mm. %3D (d) Punch diameter 75.62 mm and Die diameter = 76.0 mm. %3D

1. The appropriate punch size for a blanking operation using to perform a cold-rolled steel (half hard) circular part with diameter 75.0 mm and 2.0 mm thick is: (a) Punch diameter 77.72 mm and Die diameter = 74.50 mm. (b) Punch diameter = 73.50 mm and Die diameter 75.50 mm. %3D (c) Punch diameter 74.70 mm and Die diameter 75.0 mm. %3D (d) Punch diameter 75.62 mm and Die diameter = 76.0 mm. %3D

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

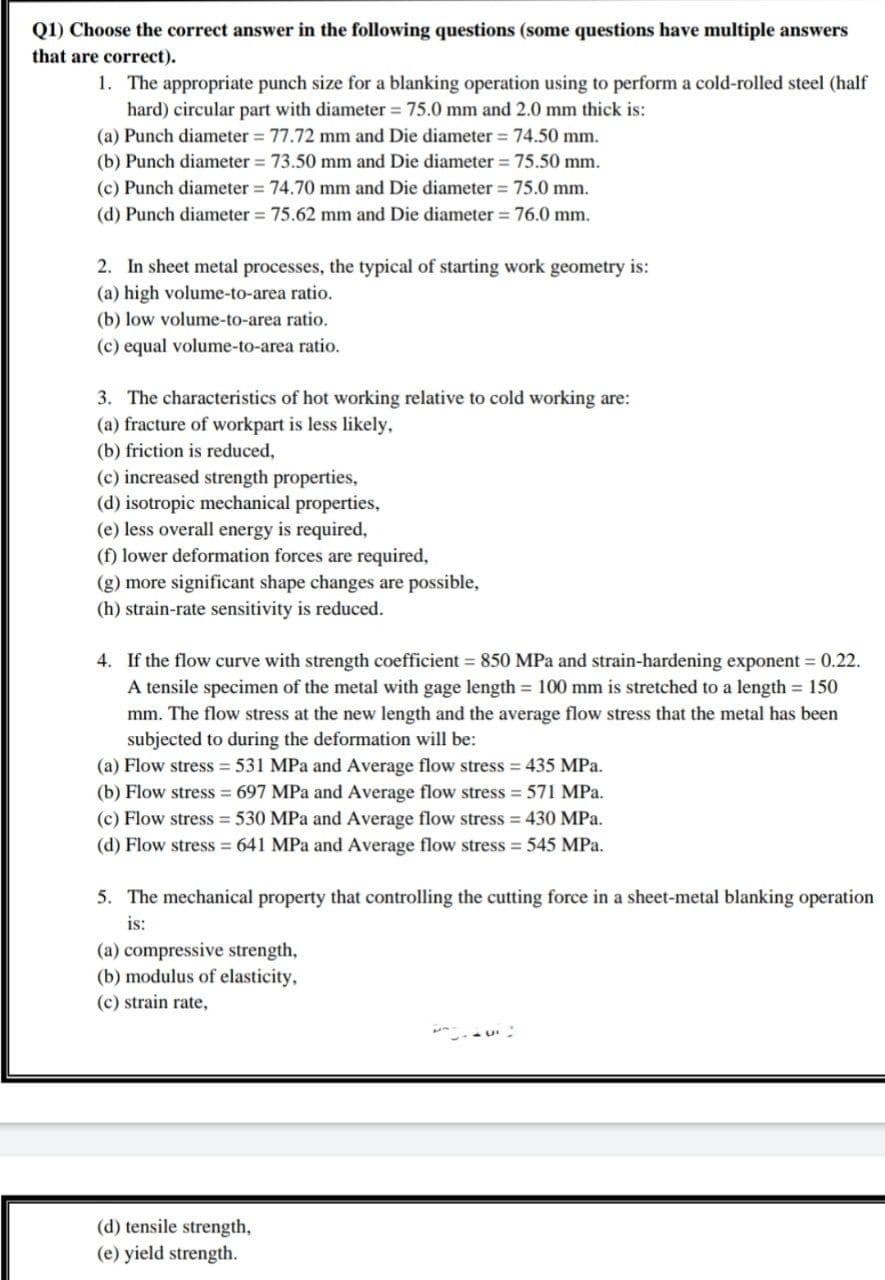

Transcribed Image Text:Q1) Choose the correct answer in the following questions (some questions have multiple answers

that are correct).

1. The appropriate punch size for a blanking operation using to perform a cold-rolled steel (half

hard) circular part with diameter = 75.0 mm and 2.0 mm thick is:

(a) Punch diameter = 77.72 mm and Die diameter = 74.50 mm.

(b) Punch diameter = 73.50 mm and Die diameter = 75.50 mm.

(c) Punch diameter = 74.70 mm and Die diameter = 75.0 mm.

(d) Punch diameter = 75.62 mm and Die diameter = 76.0 mm.

2. In sheet metal processes, the typical of starting work geometry is:

(a) high volume-to-area ratio.

(b) low volume-to-area ratio.

(c) equal volume-to-area ratio.

3. The characteristics of hot working relative to cold working are:

(a) fracture of workpart is less likely,

(b) friction is reduced,

(c) increased strength properties,

(d) isotropic mechanical properties,

(e) less overall energy is required,

(f) lower deformation forces are required,

(g) more significant shape changes are possible,

(h) strain-rate sensitivity is reduced.

4. If the flow curve with strength coefficient 850 MPa and strain-hardening exponent = 0.22.

A tensile specimen of the metal with gage length 100 mm is stretched to a length 150

mm. The flow stress at the new length and the average flow stress that the metal has been

subjected to during the deformation will be:

(a) Flow stress 531 MPa and Average flow stress = 435 MPa.

(b) Flow stress = 697 MPa and Average flow stress = 571 MPa.

(c) Flow stress = 530 MPa and Average flow stress = 430 MPa.

(d) Flow stress 641 MPa and Average flow stress = 545 MPa.

5. The mechanical property that controlling the cutting force in a sheet-metal blanking operation

is:

(a) compressive strength,

(b) modulus of elasticity,

(c) strain rate,

(d) tensile strength,

(e) yield strength.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY