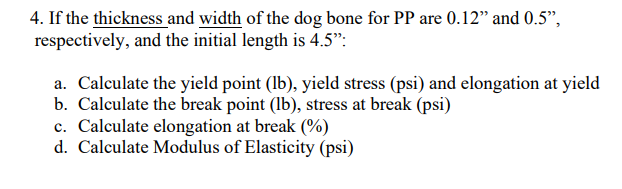

4. If the thickness and width of the dog bone for PP are 0.12" and 0.5", respectively, and the initial length is 4.5": a. Calculate the yield point (Ib), yield stress (psi) and elongation at yield b. Calculate the break point (lb), stress at break (psi) c. Calculate elongation at break (%) d. Calculate Modulus of Elasticity (psi)

4. If the thickness and width of the dog bone for PP are 0.12" and 0.5", respectively, and the initial length is 4.5": a. Calculate the yield point (Ib), yield stress (psi) and elongation at yield b. Calculate the break point (lb), stress at break (psi) c. Calculate elongation at break (%) d. Calculate Modulus of Elasticity (psi)

Mechanics of Materials (MindTap Course List)

9th Edition

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Barry J. Goodno, James M. Gere

Chapter1: Tension, Compression, And Shear

Section: Chapter Questions

Problem 1.6.5P: An aluminum bar has length L = 6 ft and diameter d = 1.375 in. The stress-strain curse for the...

Related questions

Question

Transcribed Image Text:250

3501

225

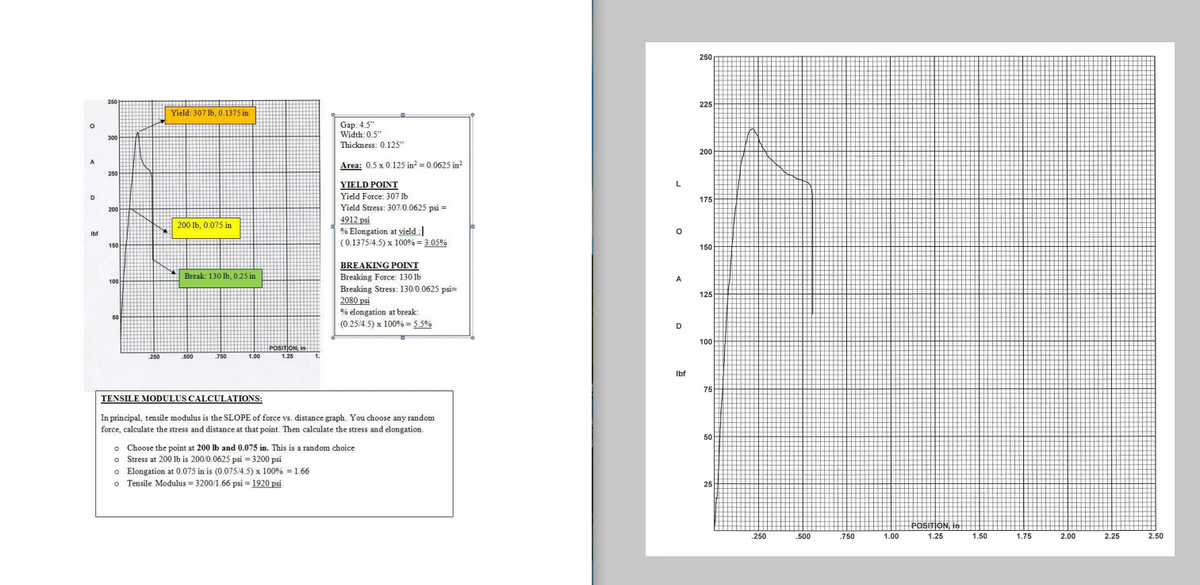

Yield: 307 lb, 0.1375 in

Gap: 4.5"

Width: 0.5"

300

Thickness: 0.125"

200

Area: 0.5 x 0.125 in? = 0.0625 in

250

YIELD POINT

L

D

Yield Force: 307 1b

175

Yield Stress: 307/0.0625 psi =

200

4912 psi

% Elongation at vield:

(0.1375/4.5) x 100% = 3.05%

200 lb, 0.075 in

Ibf

150

150

BREAKING POoINT

Break: 130 lb, 0.25 in

Breaking Force: 130 lb

Breaking Stress: 130/0.0625 psi=

2080 psi

A

100

125

% elongation at break

(0.25/4.5) x 100% = 5.5%

50

100

POSITION, in

250

500

.750

1.00

1.25

1.

Ibf

75

TENSILE MODULUS CALCULATIONS:

In principal, tensile modulus is the SLOPE of force vs. distance graph. You choose any random

force, calculate the stress and distance at that point. Then calculate the stress and elongation.

50

o Choose the point at 200 lb and 0.075 in. This is a random choice

•

o Stress at 200 1b is 200/0.0625 psi = 3200 psi

O Elongation at 0.075 in is (0.075/4.5) x 100% = 1.66

o Tensile Modulus = 3200/1.66 psi = 1920 psi

25

POSITION, in

.250

.500

.750

1.00

1.25

1.50

1.75

2.00

2.25

2.50

Transcribed Image Text:4. If the thickness and width of the dog bone for PP are 0.12" and 0.5",

respectively, and the initial length is 4.5":

a. Calculate the yield point (lb), yield stress (psi) and elongation at yield

b. Calculate the break point (lb), stress at break (psi)

c. Calculate elongation at break (%)

d. Calculate Modulus of Elasticity (psi)

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 5 steps with 5 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning