7. Consider a LiBr machine operating according to the following schematics: GENERATOR CONDENSER TEMPERATURE CONSTANT LI CCENTRATION UNES, HEAT OUT NEAT EXCHANGER SOLUTION PUMP RESTRICTOR CONCENSER PRESSURE RESTRICTOR VAPOR EAPORATOR PRESSRE SPLLOVER EVAPORATO CRYSTAL CZanoN LNE LOW TEMPERATURE HEAT OUT EWORATOR AeSoRER GLNERA TEMPERATUE TEMERATUE TEMPERATURE TEMPERATURE he system operates as follows: 1. Refrigeration load = 500 tons II. Evaporator temperature, state 8 = 41.1 °F II. Absorber equilibrium temperature, state 3 = 107.2 °F IV. Actual solution temperature, state 4 = 100.9 °F V. Solution temperature, state 5 = 170.3 °F %3D VI. Solution temperature, state 1 = 209.6 °F %3D VII. Solution temperature, state 2 = 128.1 °F Refrigerant vapor temperature, state 6 = 200 °F Refrigerant temperature, state 7 = 100 °F Refrigerant spill-over rate, state 9 = 2.5% of state 8 Concentrations of solution on a LiBr Duhring's phase diagram per above temperatures XII. Cooling water temperature entering = 85 °F VII. IX. X. XI. Chilled water temperature delta = AT = 54 – 44 = 10 °F XIII. XIV. Cooling water tower water flow rate = 1800 GPM Absolute pressure of generator = 65.9 mm Hg Mass fraction of LiBr in the solution from the absorber, Y, = 0.595 XV. XVI. XVII. Mass fraction of LiBr in the solution from the generator, Y, = 0.646 REFRGERANT VAPON PHESSURE

7. Consider a LiBr machine operating according to the following schematics: GENERATOR CONDENSER TEMPERATURE CONSTANT LI CCENTRATION UNES, HEAT OUT NEAT EXCHANGER SOLUTION PUMP RESTRICTOR CONCENSER PRESSURE RESTRICTOR VAPOR EAPORATOR PRESSRE SPLLOVER EVAPORATO CRYSTAL CZanoN LNE LOW TEMPERATURE HEAT OUT EWORATOR AeSoRER GLNERA TEMPERATUE TEMERATUE TEMPERATURE TEMPERATURE he system operates as follows: 1. Refrigeration load = 500 tons II. Evaporator temperature, state 8 = 41.1 °F II. Absorber equilibrium temperature, state 3 = 107.2 °F IV. Actual solution temperature, state 4 = 100.9 °F V. Solution temperature, state 5 = 170.3 °F %3D VI. Solution temperature, state 1 = 209.6 °F %3D VII. Solution temperature, state 2 = 128.1 °F Refrigerant vapor temperature, state 6 = 200 °F Refrigerant temperature, state 7 = 100 °F Refrigerant spill-over rate, state 9 = 2.5% of state 8 Concentrations of solution on a LiBr Duhring's phase diagram per above temperatures XII. Cooling water temperature entering = 85 °F VII. IX. X. XI. Chilled water temperature delta = AT = 54 – 44 = 10 °F XIII. XIV. Cooling water tower water flow rate = 1800 GPM Absolute pressure of generator = 65.9 mm Hg Mass fraction of LiBr in the solution from the absorber, Y, = 0.595 XV. XVI. XVII. Mass fraction of LiBr in the solution from the generator, Y, = 0.646 REFRGERANT VAPON PHESSURE

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

solve d, e , f and g only

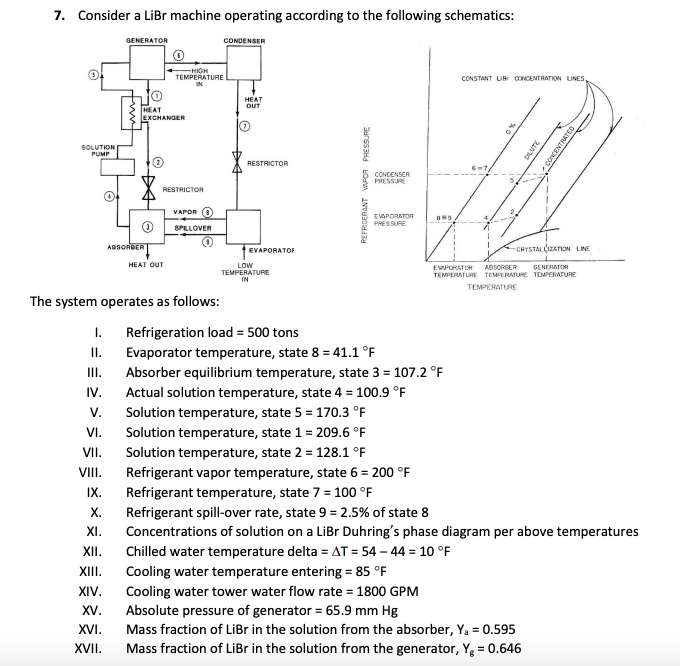

Transcribed Image Text:7. Consider a LiBr machine operating according to the following schematics:

GENERATOR

CONDENSER

-HIGH

TEMPERATURE

CONSTANT LIBr CONCENTRATION UNES.

HEAT

OUT

HEAT

EXCHANGER

SOLUTION

PUMP

RESTRICTOR

CONDENSER

PRESSURE

RESTRICTOR

VAPÓN

EVAPORATOR

PRESSURE

SPILLOVER

ADsORDER

EVAPORATOF

-CRYSTALLIZATON LINE

HEAT OUT

LOW

TEMPERATURE

IN

EVORATOR ABSORBER

TEMPERATLRS TEMPERATURE TEMPERATURE

GENERATOR

TEMPERATURE

The system operates as follows:

I.

Refrigeration load = 500 tons

Evaporator temperature, state 8 = 41.1 °F

Absorber equilibrium temperature, state 3 = 107.2 °F

Actual solution temperature, state 4 = 100.9 °F

I.

III.

IV.

V.

Solution temperature, state 5 = 170.3 °F

VI.

Solution temperature, state 1 = 209.6 °F

VII.

Solution temperature, state 2 = 128.1 °F

VIII.

Refrigerant vapor temperature, state 6 = 200 °F

IX.

Refrigerant temperature, state 7 = 100 °F

X.

Refrigerant spill-over rate, state 9 = 2.5% of state 8

Concentrations of solution on a LiBr Duhring's phase diagram per above temperatures

XI.

XII.

Chilled water temperature delta = AT = 54 – 44 = 10 °F

XIII.

Cooling water temperature entering = 85 °F

XIV.

Cooling water tower water flow rate = 1800 GPM

Absolute pressure of generator = 65.9 mm Hg

XV.

XVI.

Mass fraction of LiBr in the solution from the absorber, Y. = 0.595

XVII.

Mass fraction of LiBr in the solution from the generator, Yg = 0.646

CONCENTRATED

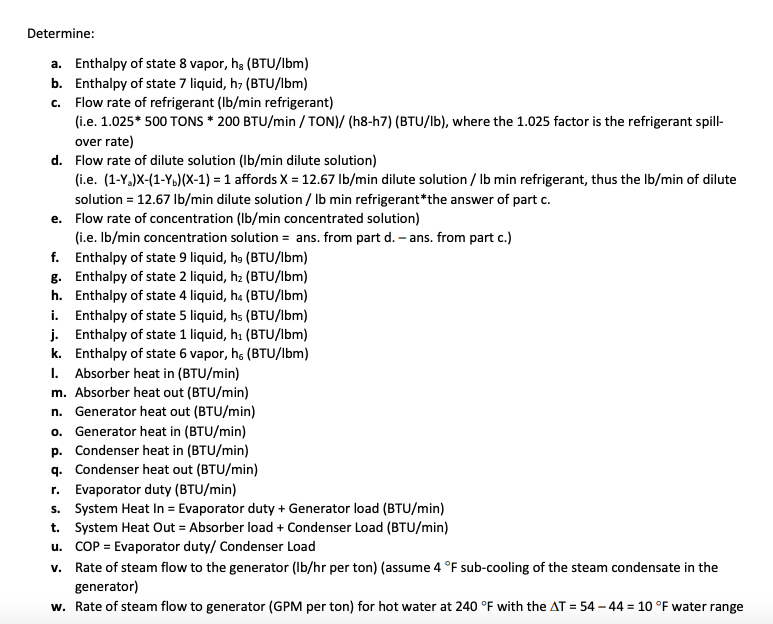

Transcribed Image Text:Determine:

a. Enthalpy of state 8 vapor, ha (BTU/lbm)

b. Enthalpy of state 7 liquid, h, (BTU/lbm)

c. Flow rate of refrigerant (Ib/min refrigerant)

(i.e. 1.025* 500 TONS * 200 BTU/min / TON)/ (h8-h7) (BTU/lb), where the 1.025 factor is the refrigerant spil-

over rate)

d. Flow rate of dilute solution (Ib/min dilute solution)

(i.e. (1-Y,)X-(1-Y,)(X-1) = 1 affords X = 12.67 Ib/min dilute solution / Ib min refrigerant, thus the Ib/min of dilute

solution = 12.67 Ib/min dilute solution / Ib min refrigerant*the answer of part c.

e. Flow rate of concentration (Ib/min concentrated solution)

(i.e. Ib/min concentration solution = ans. from part d. – ans. from part c.)

f. Enthalpy of state 9 liquid, he (BTU/lbm)

g. Enthalpy of state 2 liquid, h2 (BTU/lbm)

h. Enthalpy of state 4 liquid, ha (BTU/lbm)

i. Enthalpy of state 5 liquid, hs (BTU/lbm)

j. Enthalpy of state 1 liquid, h, (BTU/lbm)

k. Enthalpy of state 6 vapor, h, (BTU/Ibm)

I. Absorber heat in (BTU/min)

m. Absorber heat out (BTU/min)

n. Generator heat out (BTU/min)

o. Generator heat in (BTU/min)

p. Condenser heat in (BTU/min)

q. Condenser heat out (BTU/min)

r. Evaporator duty (BTU/min)

s. System Heat In = Evaporator duty + Generator load (BTU/min)

t. System Heat Out = Absorber load + Condenser Load (BTU/min)

u. COP = Evaporator duty/ Condenser Load

v. Rate of steam flow to the generator (Ib/hr per ton) (assume 4 °F sub-cooling of the steam condensate in the

generator)

w. Rate of steam flow to generator (GPM per ton) for hot water at 240 °F with the AT = 54 – 44 = 10 °F water range

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 4 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY