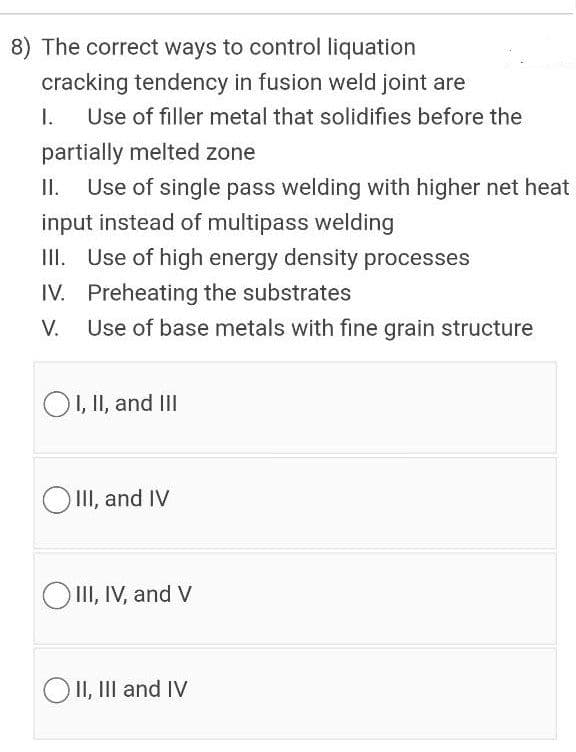

8) The correct ways to control liquation cracking tendency in fusion weld joint are I. Use of filler metal that solidifies before the partially melted zone I. Use of single pass welding with higher net heat input instead of multipass welding III. Use of high energy density processes IV. Preheating the substrates V. Use of base metals with fine grain structure

8) The correct ways to control liquation cracking tendency in fusion weld joint are I. Use of filler metal that solidifies before the partially melted zone I. Use of single pass welding with higher net heat input instead of multipass welding III. Use of high energy density processes IV. Preheating the substrates V. Use of base metals with fine grain structure

Welding: Principles and Applications (MindTap Course List)

8th Edition

ISBN:9781305494695

Author:Larry Jeffus

Publisher:Larry Jeffus

Chapter28: Filler Metal Selection

Section: Chapter Questions

Problem 22R: What alloying element used in FCA welding electrodes causes the electrode to produce centerline...

Related questions

Question

Transcribed Image Text:8) The correct ways to control liquation

cracking tendency in fusion weld joint are

I.

Use of filler metal that solidifies before the

partially melted zone

I.

Use of single pass welding with higher net heat

input instead of multipass welding

III. Use of high energy density processes

IV. Preheating the substrates

V.

Use of base metals with fine grain structure

OI, II, and III

II, and IV

OII, IV, and V

O II, III and IV

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps

Recommended textbooks for you

Welding: Principles and Applications (MindTap Cou…

Mechanical Engineering

ISBN:

9781305494695

Author:

Larry Jeffus

Publisher:

Cengage Learning

Welding: Principles and Applications (MindTap Cou…

Mechanical Engineering

ISBN:

9781305494695

Author:

Larry Jeffus

Publisher:

Cengage Learning