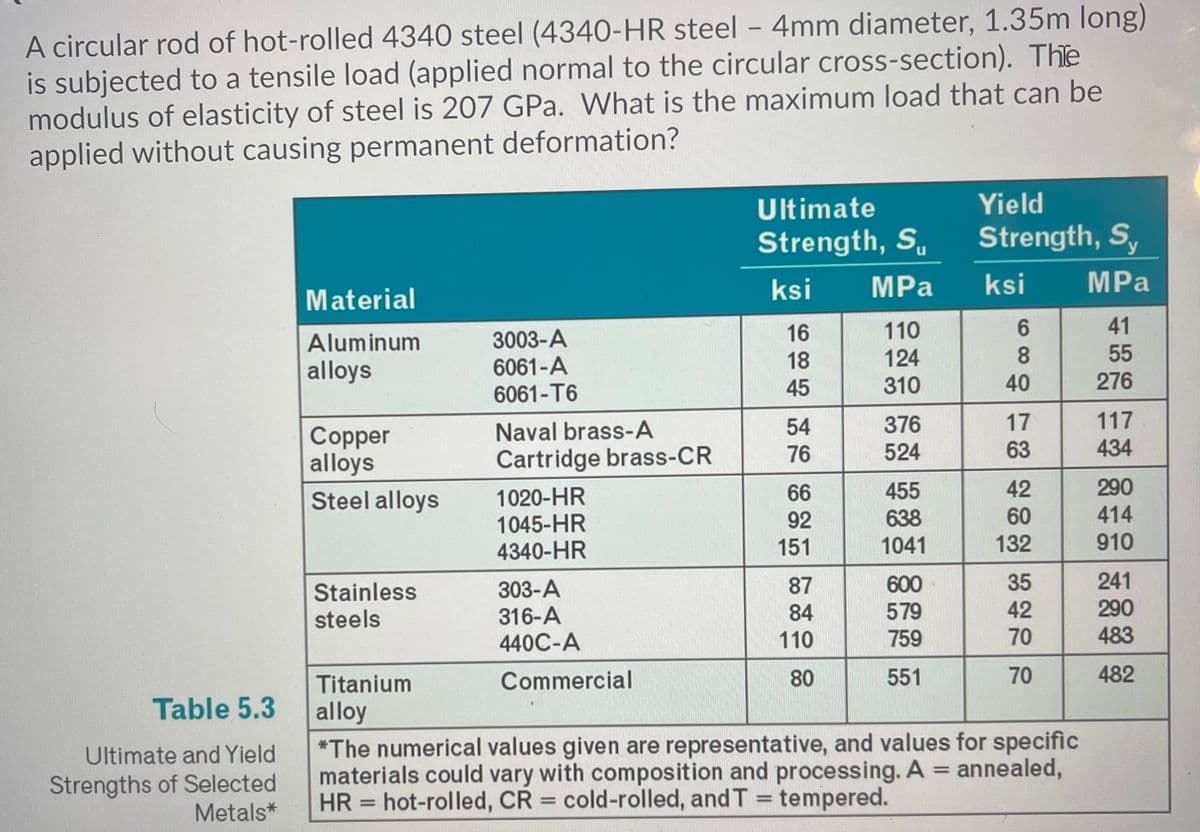

A circular rod of hot-rolled 4340 steel (4340-HR steel - 4mm diameter, 1.35m long) is subjected to a tensile load (applied normal to the circular cross-section). The modulus of elasticity of steel is 207 GPa. What is the maximum load that can be applied without causing permanent deformation? Ultimate Yield Strength, S. Strength, S, ksi MPa ksi MPa Material 41 110 124 310 6. 8. 16 3003-A 6061-A 6061-T6 Aluminum 55 alloys 18 45 40 276 117 434 17 54 76 376 524 Naval brass-A Copper alloys 63 Cartridge brass-CR 290 1020-HR 1045-HR 4340-HR 66 92 455 638 42 60 Steel alloys 414 910 151 1041 132 241 290 600 35 Stainless steels 303-A 316-A 440C-A 87 84 110 579 42 759 70 483 Titanium Commercial 80 551 70 482 Table 5.3 alloy *The numerical values given are representative, and values for specific materials could vary with composition and processing. A = annealed, HR = hot-rolled, CR = cold-rolled, and T = tempered. Ultimate and Yield Strengths of Selected Matalat

A circular rod of hot-rolled 4340 steel (4340-HR steel - 4mm diameter, 1.35m long) is subjected to a tensile load (applied normal to the circular cross-section). The modulus of elasticity of steel is 207 GPa. What is the maximum load that can be applied without causing permanent deformation? Ultimate Yield Strength, S. Strength, S, ksi MPa ksi MPa Material 41 110 124 310 6. 8. 16 3003-A 6061-A 6061-T6 Aluminum 55 alloys 18 45 40 276 117 434 17 54 76 376 524 Naval brass-A Copper alloys 63 Cartridge brass-CR 290 1020-HR 1045-HR 4340-HR 66 92 455 638 42 60 Steel alloys 414 910 151 1041 132 241 290 600 35 Stainless steels 303-A 316-A 440C-A 87 84 110 579 42 759 70 483 Titanium Commercial 80 551 70 482 Table 5.3 alloy *The numerical values given are representative, and values for specific materials could vary with composition and processing. A = annealed, HR = hot-rolled, CR = cold-rolled, and T = tempered. Ultimate and Yield Strengths of Selected Matalat

Mechanics of Materials (MindTap Course List)

9th Edition

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Barry J. Goodno, James M. Gere

Chapter1: Tension, Compression, And Shear

Section: Chapter Questions

Problem 1.7.1P: A high-strength steel bar used in a large crane has a diameter d = 2.00 in. (sec figure). The steel...

Related questions

Question

Transcribed Image Text:A circular rod of hot-rolled 4340 steel (4340-HR steel – 4mm diameter, 1.35m long)

is subjected to a tensile load (applied normal to the circular cross-section). The

modulus of elasticity of steel is 207 GPa. What is the maximum load that can be

applied without causing permanent deformation?

Ultimate

Yield

Strength, S.

Strength, S,

ksi

MPa

ksi

MPa

Material

6.

41

110

124

16

3003-A

6061-A

6061-T6

Aluminum

18

8.

55

alloys

45

310

40

276

Naval brass-A

54

376

17

117

Copper

alloys

Cartridge brass-CR

76

524

63

434

66

455

42

290

1020-HR

1045-HR

4340-HR

Steel alloys

92

638

60

414

151

1041

132

910

87

600

35

241

Stainless

steels

303-A

316-A

440C-A

84

579

42

290

110

759

70

483

Titanium

Commercial

80

551

70

482

Table 5.3

alloy

*The numerical values given are representative, and values for specific

materials could vary with composition and processing. A = annealed,

HR = hot-rolled, CR = cold-rolled, and T = tempered.

Ultimate and Yield

%3D

Strengths of Selected

Metals*

Expert Solution

Step 1

Given Data:-

4340 Steel

Diameter=4mm

Length=1.35m

Modulus of Elasticity=207Gpa

Yield-Strength =910MPa

Ultimate Strength=1041MPa

To-Find:-

Maximum Load

Trending now

This is a popular solution!

Step by step

Solved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning