A manufacturer produces three models, I, II, and III, of a certain product using raw materials A and B. The following table gives the data for the problem. Requirement per unit Raw material I II III Availability Raw Material A 2 4 7797 Raw Material B 4 8 6701 Minimum demand 180 298 250 Price per unit ($) 35 25 55 The labor time per unit of model I is twice that of II and four times that of III. The entire labor force of the factory can produce the equivalent of 1987 units of model I. Market requirements specify the ratios 4:2:5 for the production of three respective models. Complete the LP model of the problem. Note: If any of the answers have decimal points, use a dot () to separate them. DON'T use comma or other symbols for the decimals. Decision variables: X = # of unites of model j (j=1,2,3) Objective function: Maximize z = * X,+ X2+ * X3 Subject to: *X1 + 4*X2 + 5*X3 s 4*X1 + *X2 + 8*X3 s Xị + 0.5*X2 + *X3 s 0.25*X1 : 0.5*X2 0.5*X2 *X3 X1 180, X2 X3 250 All variables are non-negative integers.

A manufacturer produces three models, I, II, and III, of a certain product using raw materials A and B. The following table gives the data for the problem. Requirement per unit Raw material I II III Availability Raw Material A 2 4 7797 Raw Material B 4 8 6701 Minimum demand 180 298 250 Price per unit ($) 35 25 55 The labor time per unit of model I is twice that of II and four times that of III. The entire labor force of the factory can produce the equivalent of 1987 units of model I. Market requirements specify the ratios 4:2:5 for the production of three respective models. Complete the LP model of the problem. Note: If any of the answers have decimal points, use a dot () to separate them. DON'T use comma or other symbols for the decimals. Decision variables: X = # of unites of model j (j=1,2,3) Objective function: Maximize z = * X,+ X2+ * X3 Subject to: *X1 + 4*X2 + 5*X3 s 4*X1 + *X2 + 8*X3 s Xị + 0.5*X2 + *X3 s 0.25*X1 : 0.5*X2 0.5*X2 *X3 X1 180, X2 X3 250 All variables are non-negative integers.

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter6: Optimization Models With Integer Variables

Section: Chapter Questions

Problem 49P

Related questions

Question

100%

Operations research Optimization

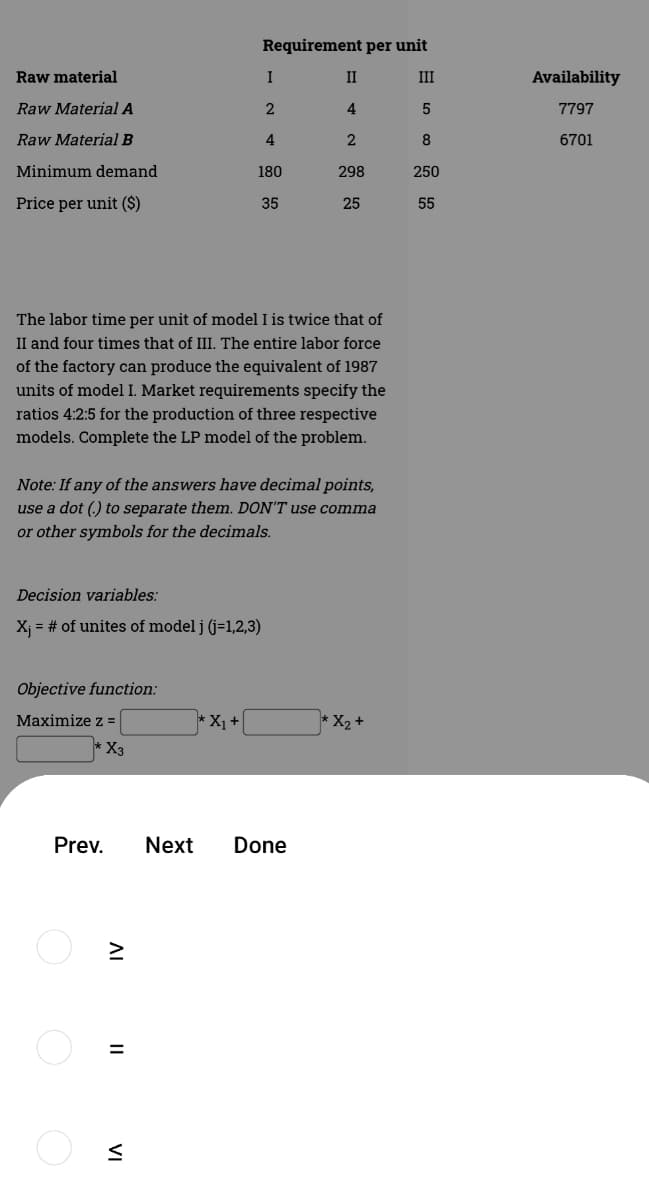

Transcribed Image Text:Requirement per unit

Raw material

I

II

II

Availability

Raw Material A

4

7797

Raw Material B

4

2

8

6701

Minimum demand

180

298

250

Price per unit ($)

35

25

55

The labor time per unit of model I is twice that of

II and four times that of III. The entire labor force

of the factory can produce the equivalent of 1987

units of model I. Market requirements specify the

ratios 4:2:5 for the production of three respective

models. Complete the LP model of the problem.

Note: If any of the answers have decimal points,

use a dot (.) to separate them. DON'T use comma

or other symbols for the decimals.

Decision variables:

X; = # of unites of model j (j=1,2,3)

Objective function:

Maximize z =

*X1+

* X2 +

* X3

Prev.

Next

Done

II

VI

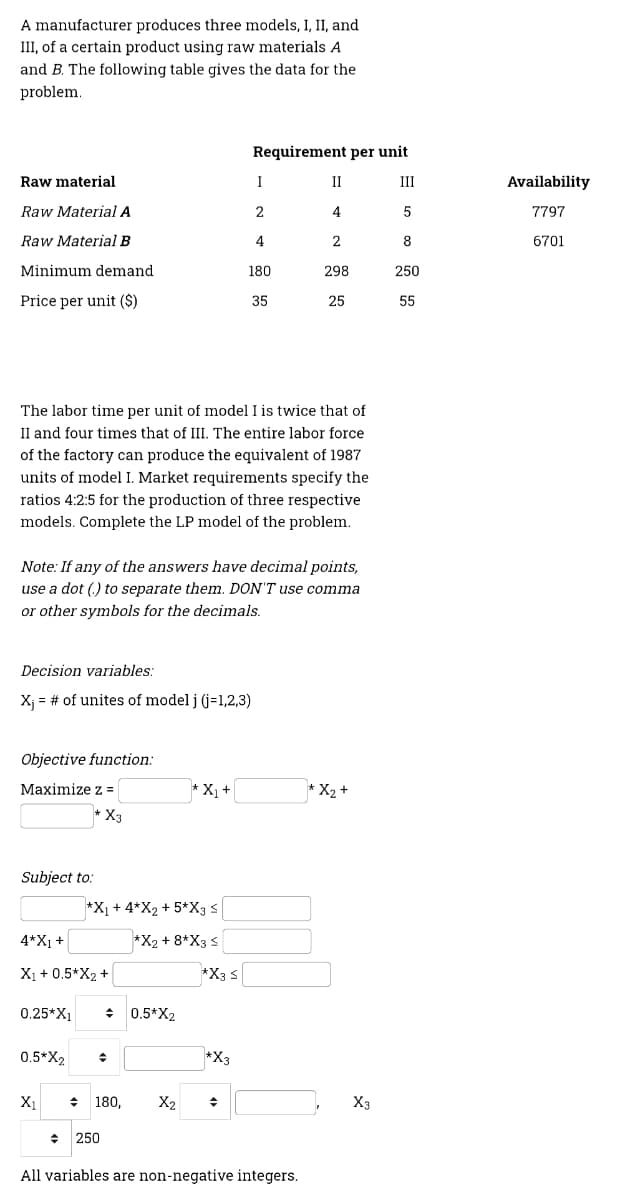

Transcribed Image Text:A manufacturer produces three models, I, II, and

III, of a certain product using raw materials A

and B. The following table gives the data for the

problem.

Requirement per unit

Raw material

I

II

III

Availability

Raw Material A

2

4

5

7797

Raw Material B

4

2

8

6701

Minimum demand

180

298

250

Price per unit ($)

35

25

55

The labor time per unit of model I is twice that of

II and four times that of III. The entire labor force

of the factory can produce the equivalent of 1987

units of model I. Market requirements specify the

ratios 4:2:5 for the production of three respective

models. Complete the LP model of the problem.

Note: If any of the answers have decimal points,

use a dot (.) to separate them. DON'T use comma

or other symbols for the decimals.

Decision variables:

X; = # of unites of model j (j=1,2,3)

Objective function:

Maximize z =

* X1+

* X2+

* X3

Subject to:

*X1 + 4*X2 + 5*X3 s

4*X1 +

*X2 + 8*X3 s

X1 + 0.5*X2 +

*X3 s

0.25*X1

+ 0.5*X2

0.5*X2

*X3

X1

+ 180,

X2

X3

250

All variables are non-negative integers.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps with 1 images

Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,