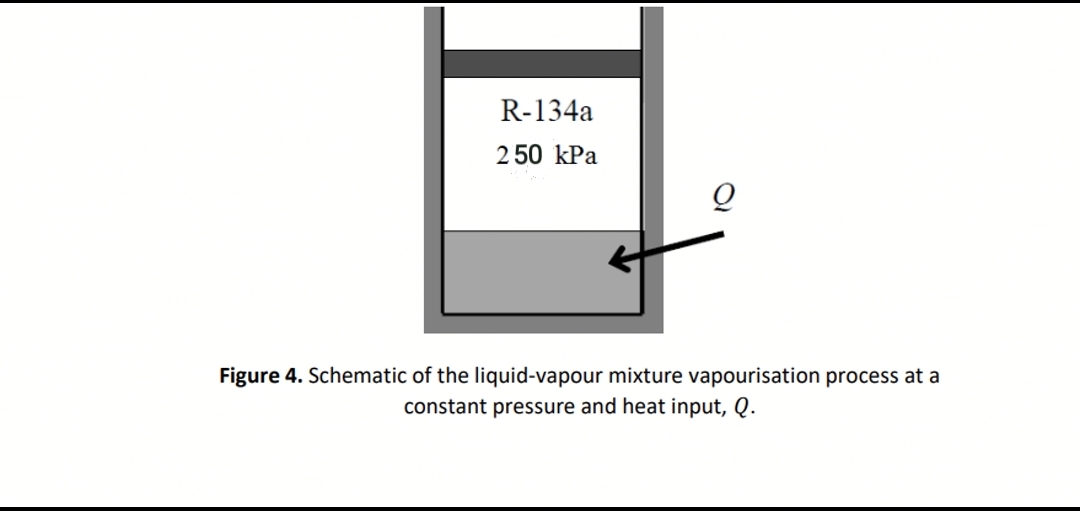

A phase change, or transition, occurs when a substance undergoes a change in state on a molecular level. In most substances, changes in temperature or pressure result in a substance phase change. There are several processes of phase changes, including fusion, solidification, vaporization, condensation, sublimation and physical vapor deposition. A vapour compression cycle is used in most household refrigerators, refrigerator-freezers and freezers. The performance of the refrigerators heavily depends on the phase change properties of the refrigerant used. Thus, it is of primary importance to any industrial designer to have a good understanding of the phase change behaviour of substances which will allow them for design modifications and optimisations. In our problem, a cylinder is initially filled with saturated liquid-vapour mixture of R-134a (a common refrigerant) at a specified pressure, 250 kPa and vapour quality of 0.25. A constant heat input, Q, is transferred to the cylinder until the refrigerant vaporizes completely at constant pressure. By clearly stating your assumptions throughout, 1. Analytically describe the Fluid Mechanics and Thermodynamics working principles of refrigerators operating using a vapour compression cycle; 2. Determine the initial volume; 3. Determine the work done; 4. Determine the total heat transfer; 5. Show the process on a P-v diagram; 6. Discuss the desired properties of substances that are used as refrigerants in the industry and potential problems arising. Share your view on the potential usage of CO₂ as a refrigerant in commercial refrigerators.

A phase change, or transition, occurs when a substance undergoes a change in state on a molecular level. In most substances, changes in temperature or pressure result in a substance phase change. There are several processes of phase changes, including fusion, solidification, vaporization, condensation, sublimation and physical vapor deposition. A vapour compression cycle is used in most household refrigerators, refrigerator-freezers and freezers. The performance of the refrigerators heavily depends on the phase change properties of the refrigerant used. Thus, it is of primary importance to any industrial designer to have a good understanding of the phase change behaviour of substances which will allow them for design modifications and optimisations. In our problem, a cylinder is initially filled with saturated liquid-vapour mixture of R-134a (a common refrigerant) at a specified pressure, 250 kPa and vapour quality of 0.25. A constant heat input, Q, is transferred to the cylinder until the refrigerant vaporizes completely at constant pressure. By clearly stating your assumptions throughout, 1. Analytically describe the Fluid Mechanics and Thermodynamics working principles of refrigerators operating using a vapour compression cycle; 2. Determine the initial volume; 3. Determine the work done; 4. Determine the total heat transfer; 5. Show the process on a P-v diagram; 6. Discuss the desired properties of substances that are used as refrigerants in the industry and potential problems arising. Share your view on the potential usage of CO₂ as a refrigerant in commercial refrigerators.

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

Transcribed Image Text:R-134a

250 kPa

Q

Figure 4. Schematic of the liquid-vapour mixture vapourisation process at a

constant pressure and heat input, Q.

Transcribed Image Text:A phase change, or transition, occurs when a substance undergoes a change in state on a molecular

level. In most substances, changes in temperature or pressure result in a substance phase change.

There are several processes of phase changes, including fusion, solidification, vaporization,

condensation, sublimation and physical vapor deposition.

A vapour compression cycle is used in most household refrigerators, refrigerator-freezers and

freezers. The performance of the refrigerators heavily depends on the phase change properties of the

refrigerant used. Thus, it is of primary importance to any industrial designer to have a good

understanding of the phase change behaviour of substances which will allow them for design

modifications and optimisations.

In our problem, a cylinder is initially filled with saturated liquid-vapour mixture of R-134a (a common

refrigerant) at a specified pressure, 250 kPa and vapour quality of 0.25. A constant heat input, Q, is

transferred to the cylinder until the refrigerant vaporizes completely at constant pressure. By clearly

stating your assumptions throughout,

1. Analytically describe the Fluid Mechanics and Thermodynamics working principles of

refrigerators operating using a vapour compression cycle;

2. Determine the initial volume;

3. Determine the work done;

4. Determine the total heat transfer;

5. Show the process on a P-v diagram;

6. Discuss the desired properties of substances that are used as refrigerants in the industry and

potential problems arising. Share your view on the potential usage of CO2 as a refrigerant in

commercial refrigerators.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 4 steps with 4 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY