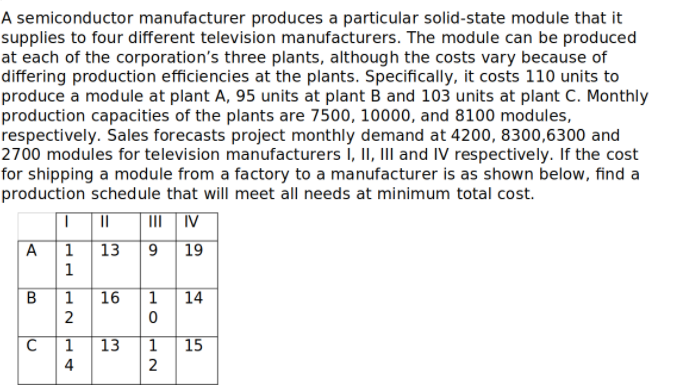

A semiconductor manufacturer produces a particular solid-state module that it supplies to four different television manufacturers. The module can be produced at each of the corporation's three plants, although the costs vary because of differing production efficiencies at the plants. Specifically, it costs 110 units to produce a module at plant A, 95 units at plant B and 103 units at plant C. Monthly production capacities of the plants are 7500, 10000, and 8100 modules, respectively. Sales forecasts project monthly demand at 4200, 8300,6300 and 2700 modules for television manufacturers i, II, III and IV respectively. If the cost for shipping a module from a factory to a manufacturer is as shown below, find a production schedule that will meet all needs at minimum total cost.

A semiconductor manufacturer produces a particular solid-state module that it supplies to four different television manufacturers. The module can be produced at each of the corporation's three plants, although the costs vary because of differing production efficiencies at the plants. Specifically, it costs 110 units to produce a module at plant A, 95 units at plant B and 103 units at plant C. Monthly production capacities of the plants are 7500, 10000, and 8100 modules, respectively. Sales forecasts project monthly demand at 4200, 8300,6300 and 2700 modules for television manufacturers i, II, III and IV respectively. If the cost for shipping a module from a factory to a manufacturer is as shown below, find a production schedule that will meet all needs at minimum total cost.

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter5: Network Models

Section: Chapter Questions

Problem 80P

Related questions

Question

Transcribed Image Text:A semiconductor manufacturer produces a particular solid-state module that it

supplies to four different television manufacturers. The module can be produced

at each of the corporation's three plants, although the costs vary because of

differing production efficiencies at the plants. Specifically, it costs 110 units to

produce a module at plant A, 95 units at plant B and 103 units at plant C. Monthly

production capacities of the plants are 7500, 10000, and 8100 modules,

respectively. Sales forecasts project monthly demand at 4200, 8300,6300 and

2700 modules for television manufacturers i, II, IllI and IV respectively. If the cost

for shipping a module from a factory to a manufacturer is as shown below, find a

production schedule that will meet all needs at minimum total cost.

| ||

| III| IV

A

1

9

19

13

1

1

16

1

14

2

1

13

1

15

4

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps with 3 images

Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,