Assume that there is only 1 worker in total for building bunk beds (i.c., 1 worker performs each step). What is the capacity in beds per week for the process?

Assume that there is only 1 worker in total for building bunk beds (i.c., 1 worker performs each step). What is the capacity in beds per week for the process?

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter2: Introduction To Spreadsheet Modeling

Section: Chapter Questions

Problem 20P: Julie James is opening a lemonade stand. She believes the fixed cost per week of running the stand...

Related questions

Question

Please read the case study - Operations Management Case Study - process.pdf " to learn the general areas of importance in process analysis. Understanding process is critical to creation of an efficient flow in designing manufacturing or services.

Please study the Case Study and answer the 8 questions in Appendix 2 on page 17.

Help below-

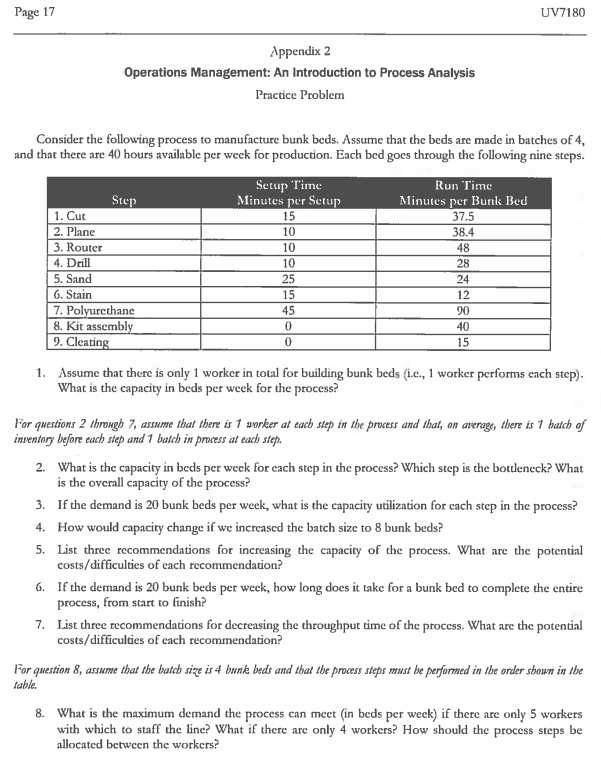

Transcribed Image Text:Page 17

Appendix 2

Operations Management: An Introduction to Process Analysis

Practice Problem

Consider the following process to manufacture bunk beds. Assume that the beds are made in batches of 4,

and that there are 40 hours available per week for production. Each bed goes through the following nine steps.

Step

1. Cut

2. Plane

3. Router

4. Drill

5. Sand

6. Stain

7. Polyurethane

8. Kit assembly

9. Cleating

Setup Time

Minutes per Setup

15

10

10

10

25

15

45

0

0

Run Time

Minutes per Bunk Bed

37.5

38.4

48

28

UV7180

24

12

90

40

15

1. Assume that there is only 1 worker in total for building bunk beds (i.c., 1 worker performs each step).

What is the capacity in beds per week for the process?

For questions 2 through 7, assume that there is 1 worker at each step in the process and that, on average, there is 1 batch of

inventory before each step and 1 batch in process at each step.

2. What is the capacity in beds per week for each step in the process? Which step is the bottleneck? What

is the overall capacity of the process?

3.

If the demand is 20 bunk beds per week, what is the capacity utilization for each step in the process?

4. How would capacity change if we increased the batch size to 8 bunk beds?

5. List three recommendations for increasing the capacity of the process. What are the potential

costs/difficulties of each recommendation?

6. If the demand is 20 bunk beds per week, how long does it take for a bunk bed to complete the entire

process, from start to finish?

7.

List three recommendations for decreasing the throughput time of the process. What are the potential

costs/difficulties of each recommendation?

For question 8, assume that the batch size is 4 bunk beds and that the process steps must be performed in the order shown in the

table.

8. What is the maximum demand the process can meet (in beds per week) if there are only 5 workers

with which to staff the line? What if there are only 4 workers? How should the process steps be

allocated between the workers?

Transcribed Image Text:UNIVERSITY VIRGINIA

Operations Management: An Introduction to Process Analysis

Firms exist to create and deliver value to customers, shareholders, employees, and society. Operations

Management is focused on the means the underlying processes by which firms create and deliver value. A

firm's processes transform inputs such as labor, capital, materials, and information into outputs of greater value,

in the form of products and services. For example, in a bank loan-approval process, bank staff and computer

systems process information about a loan applicant and return either an approval or a rejection of the loan

application. In an airport security check-in process, security personnel use equipment to inspect passengers and

their luggage and either deem them fit for boarding or detain them for further inspection. In a car assembly

process, workers and equipment convert car components into assembled vehicles.

In this technical note, we illustrate several process-analysis fundamentals. To do this, we utilize a simple

example of a Hawaiian-shirt production process. The note is divided into the following six sections:

1. Mapping a Process

2. Calculating Capacity and Identifying Bottlenecks

3. Load Balancing

4.

5.

6. Summary

Appendix 1: Process-Map Example

Appendix 2: Practice Problem

Appendix 3: Glossary

Setup Times and Batches

Little's Law

1. Mapping a Process

To manage or improve a process, it is important to first understand it. Almost always, the first step of any

process analysis should be to map or draw out the existing process. Process mapping or process-flow

diagramming is a visual tool that helps achieve this. Consider the following example of a Hawaiian-shirt

production process. This process includes the following four steps:

Step 1 (cutting): A roll of fabric (with the desired shirt pattern) is gathered and laid out on the cutting table.

The necessary pieces for a shirt (one torso, two sleeves, one collar, and one shirt-pocket) are then cut using a

semiautomatic fabric cutter. The cut pieces for the shirt are then placed into a tote and staged before step 2.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps

Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning

Production and Operations Analysis, Seventh Editi…

Operations Management

ISBN:

9781478623069

Author:

Steven Nahmias, Tava Lennon Olsen

Publisher:

Waveland Press, Inc.