B) Lathe. C) milling machine. D) planner. withstand the forces of the process. A) drill press. E) broaching. F) shaper. G) none of the previous answers. 5) Boring is an operation which is normally performed on which one of the following machines: A) vertical milling B) Lathe. C) horizontal milling machine. D) planner. E) broaching machine. F) shaper. G) none of the previous answers. machine. 6) Countersinking is a process related to:- A) Turning. B) horizontal milling machine. C) Broaching. D) drilling. E) planning. F) shaping. G) none of the previous answers. Diamond cutting tool tine are attached to the carbide substrato inpede in cathed

B) Lathe. C) milling machine. D) planner. withstand the forces of the process. A) drill press. E) broaching. F) shaper. G) none of the previous answers. 5) Boring is an operation which is normally performed on which one of the following machines: A) vertical milling B) Lathe. C) horizontal milling machine. D) planner. E) broaching machine. F) shaper. G) none of the previous answers. machine. 6) Countersinking is a process related to:- A) Turning. B) horizontal milling machine. C) Broaching. D) drilling. E) planning. F) shaping. G) none of the previous answers. Diamond cutting tool tine are attached to the carbide substrato inpede in cathed

Precision Machining Technology (MindTap Course List)

2nd Edition

ISBN:9781285444543

Author:Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher:Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Chapter2: Measurement, Materials, And Safety

Section2.5: Quality Assurance, Process Planning, And Quality Control

Problem 10RQ: If an X-bar chart graph falls below the LCL or rises above the UCL, a machining process is said to...

Related questions

Question

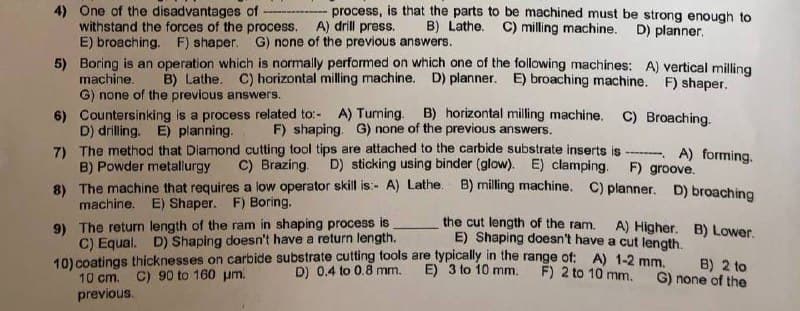

Transcribed Image Text:4) One of the disadvantages of

process, is that the parts to be machined must be strong enough to

withstand the forces of the process. A) drill press. B) Lathe. C) milling machine. D) planner.

E) broaching. F) shaper. G) none of the previous answers.

5) Boring is an operation which is normally performed on which one of the following machines: A) vertical milling

B) Lathe. C) horizontal milling machine. D) planner. E) broaching machine. F) shaper.

machine.

G) none of the previous answers.

6) Countersinking is a process related to:- A) Turning. B) horizontal milling machine. C) Broaching.

D) drilling. E) planning. F) shaping. G) none of the previous answers.

B) Powder metallurgy

7) The method that Diamond cutting tool tips are attached to the carbide substrate inserts is A) forming.

C) Brazing. D) sticking using binder (glow). E) clamping. F) groove.

8) The machine that requires a low operator skill is:- A) Lathe. B) milling machine. C) planner. D) broaching

machine. E) Shaper. F) Boring.

9) The return length of the ram in shaping process is

C) Equal. D) Shaping doesn't have a return length.

the cut length of the ram. A) Higher. B) Lower.

E) Shaping doesn't have a cut length.

10) coatings thicknesses on carbide substrate cutting tools are typically in the range of: A) 1-2 mm.

F) 2 to 10 mm.

D) 0.4 to 0.8 mm.

E) 3 to 10 mm.

B) 2 to

G) none of the

C) 90 to 160 μm.

10 cm.

previous.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Precision Machining Technology (MindTap Course Li…

Mechanical Engineering

ISBN:

9781285444543

Author:

Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher:

Cengage Learning

Refrigeration and Air Conditioning Technology (Mi…

Mechanical Engineering

ISBN:

9781305578296

Author:

John Tomczyk, Eugene Silberstein, Bill Whitman, Bill Johnson

Publisher:

Cengage Learning

Precision Machining Technology (MindTap Course Li…

Mechanical Engineering

ISBN:

9781285444543

Author:

Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher:

Cengage Learning

Refrigeration and Air Conditioning Technology (Mi…

Mechanical Engineering

ISBN:

9781305578296

Author:

John Tomczyk, Eugene Silberstein, Bill Whitman, Bill Johnson

Publisher:

Cengage Learning