Consider a grinding operation which utilises the following process parameters: wheel speed of 1450m/min, a crossfeed of 5 mm, infeed of 0.07 mm and workspeed of 0.25 m/s. For a cutting wheel of diameter 150 mm with 0.75 grits/mm? active grits per area, calculate: i) the material removal rate; ii) the number of chips formed per unit time for the portion of the operation when the wheel is engaged in the work;

Consider a grinding operation which utilises the following process parameters: wheel speed of 1450m/min, a crossfeed of 5 mm, infeed of 0.07 mm and workspeed of 0.25 m/s. For a cutting wheel of diameter 150 mm with 0.75 grits/mm? active grits per area, calculate: i) the material removal rate; ii) the number of chips formed per unit time for the portion of the operation when the wheel is engaged in the work;

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

Transcribed Image Text:e) Consider a grinding operation which utilises the following process parameters: wheel

speed of 1450m/min, a crossfeed of 5 mm, infeed of 0.07 mm and workspeed of

0.25 m/s. For a cutting wheel of diameter 150 mm with 0.75 grits/mm? active grits

per area, calculate:

i) the material removal rate;

ii) the number of chips formed per unit time for the portion of the operation when

the wheel is engaged in the work;

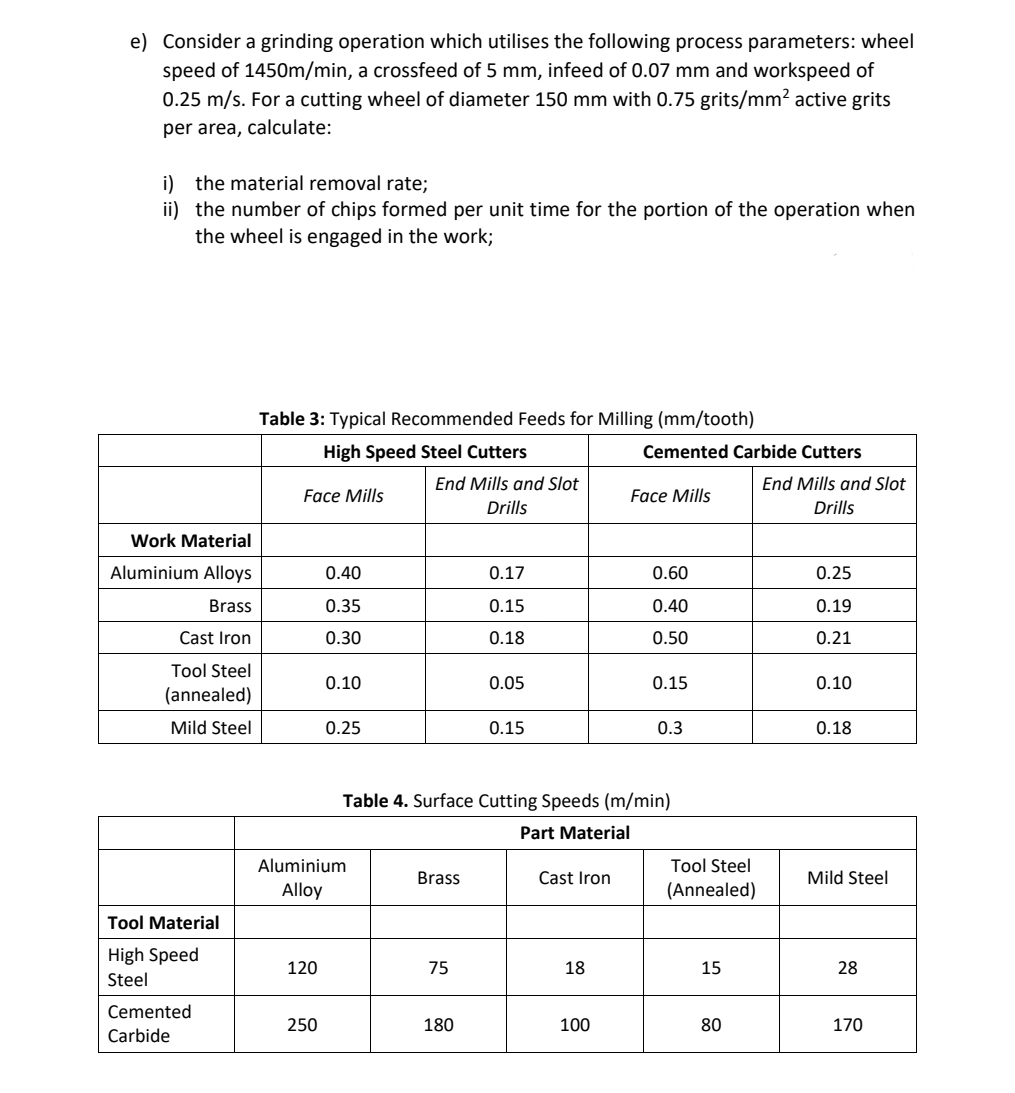

Table 3: Typical Recommended Feeds for Milling (mm/tooth)

High Speed Steel Cutters

Cemented Carbide Cutters

End Mills and Slot

End Mills and Slot

Face Mills

Face Mills

Drills

Drills

Work Material

Aluminium Alloys

0.40

0.17

0.60

0.25

Brass

0.35

0.15

0.40

0.19

Cast Iron

0.30

0.18

0.50

0.21

Tool Steel

0.10

0.05

0.15

0.10

(annealed)

Mild Steel

0.25

0.15

0.3

0.18

Table 4. Surface Cutting Speeds (m/min)

Part Material

Aluminium

Tool Steel

Brass

Cast Iron

Mild Steel

Alloy

(Annealed)

Tool Material

High Speed

120

75

18

15

28

Steel

Cemented

250

180

100

80

170

Carbide

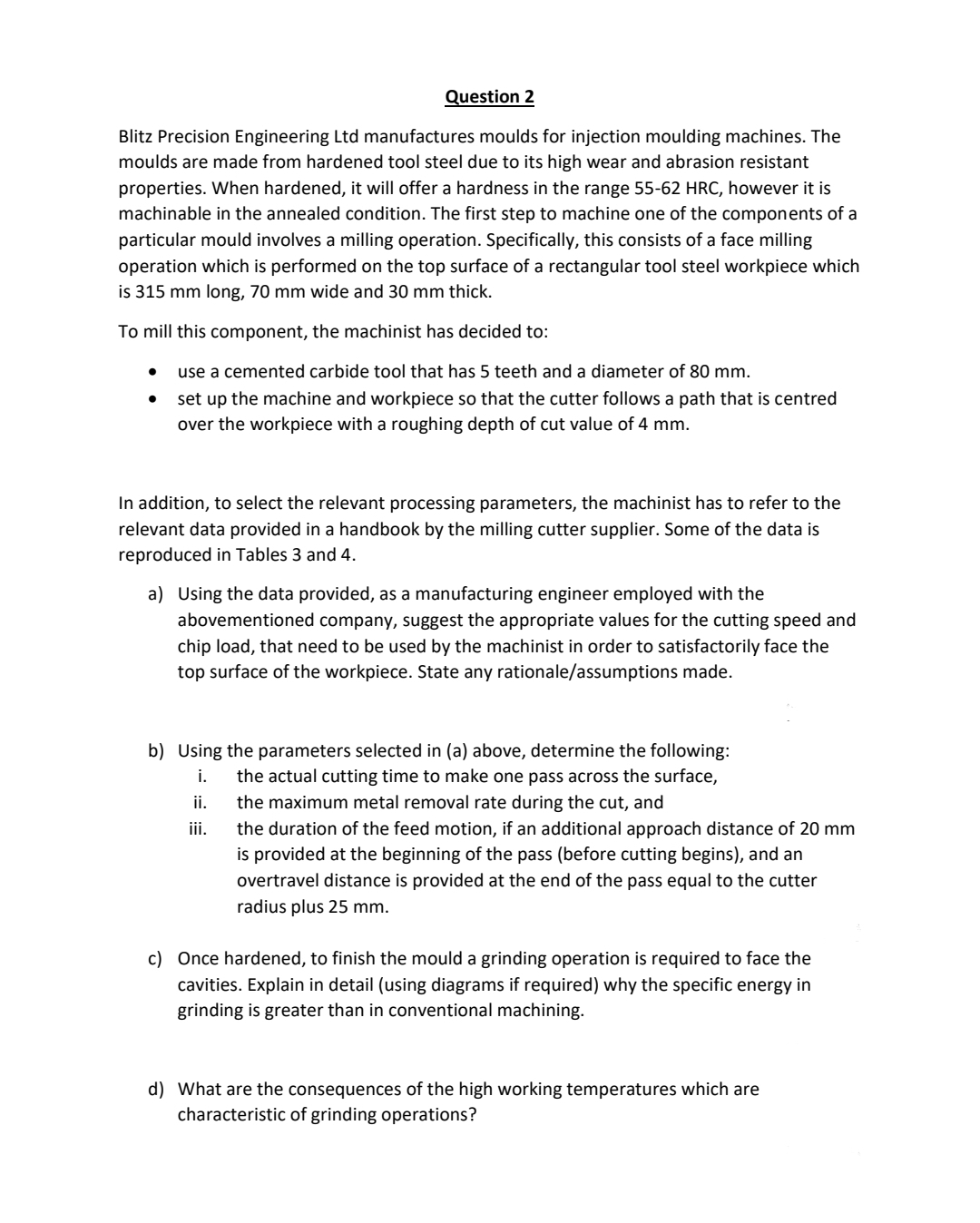

Transcribed Image Text:Question 2

Blitz Precision Engineering Ltd manufactures moulds for injection moulding machines. The

moulds are made from hardened tool steel due to its high wear and abrasion resistant

properties. When hardened, it will offer a hardness in the range 55-62 HRC, however it is

machinable in the annealed condition. The first step to machine one of the components of a

particular mould involves a milling operation. Specifically, this consists of a face milling

operation which is performed on the top surface of a rectangular tool steel workpiece which

is 315 mm long, 70 mm wide and 30 mm thick.

To mill this component, the machinist has decided to:

use a cemented carbide tool that has 5 teeth and a diameter of 80 mm.

set up the machine and workpiece so that the cutter follows a path that is centred

over the workpiece with a roughing depth of cut value of 4 mm.

In addition, to select the relevant processing parameters, the machinist has to refer to the

relevant data provided in a handbook by the milling cutter supplier. Some of the data is

reproduced in Tables 3 and 4.

a) Using the data provided, as a manufacturing engineer employed with the

abovementioned company, suggest the appropriate values for the cutting speed and

chip load, that need to be used by the machinist in order to satisfactorily face the

top surface of the workpiece. State any rationale/assumptions made.

b) Using the parameters selected in (a) above, determine the following:

the actual cutting time to make one pass across the surface,

i.

ii.

the maximum metal removal rate during the cut, and

ii.

the duration of the feed motion, if an additional approach distance of 20 mm

is provided at the beginning of the pass (before cutting begins), and an

overtravel distance is provided at the end of the pass equal to the cutter

radius plus 25 mm.

c) Once hardened, to finish the mould a grinding operation is required to face the

cavities. Explain in detail (using diagrams if required) why the specific energy in

grinding is greater than in conventional machining.

d) What are the consequences of the high working temperatures which are

characteristic of grinding operations?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps with 2 images

Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY