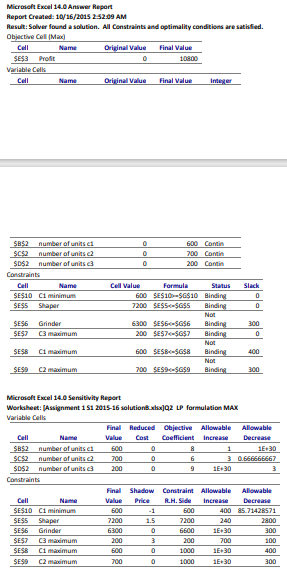

CWD Manufacturing makes three components for sale to refrigeration companies. The components are processed on two machines: a shaper and a grinder. The times (in minutes) required on each machine are as follows: Machine Component Shaper Grinder 1 6 4 2 4 5 3 4 2 The shaper is available for 120 hours, and the grinder is available for 110 hours. No more than 200 units of component 3 can be sold, but up to 1000 units of each of the other components can be sold. In fact, the company already has orders for 600 units of component 1 that must be satisfied. The profit contributions for components 1, 2, and 3 are $8, $6, and $9, respectively. (see image) If there are two possible answers one will suffice. Where necessary a range analysis must be shown.(convert to minutes) a) What is the optimal solution (in words)? b) An additional 4 hours of shaper time became available. Evaluate the effect? Explain c) Two hours of Grinder time was lost. Evaluate the effect?

Question 2

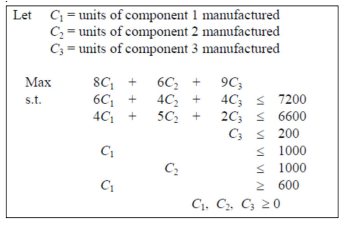

CWD Manufacturing makes three components for sale to refrigeration companies. The

components are processed on two machines: a shaper and a grinder. The times (in minutes)

required on each machine are as follows:

Machine

| Component | Shaper | Grinder |

| 1 | 6 | 4 |

| 2 | 4 | 5 |

| 3 | 4 | 2 |

The shaper is available for 120 hours, and the grinder is available for 110 hours. No more than

200 units of component 3 can be sold, but up to 1000 units of each of the other components can

be sold. In fact, the company already has orders for 600 units of component 1 that must be

satisfied. The profit contributions for components 1, 2, and 3 are $8, $6, and $9, respectively.

(see image)

If there are two possible answers one will suffice. Where necessary a range analysis must be shown.(convert to minutes)

a) What is the optimal solution (in words)?

b) An additional 4 hours of shaper time became available. Evaluate the effect? Explain

c) Two hours of Grinder time was lost. Evaluate the effect?

d) An additional 20 units of component 3 was requested. Evaluate the effect

e) The demand for component 2 decreased by 30 units. Evaluate the effect

f) Suppose that the profit contribution of component 1 increases to $9.00.

What is the new optimal solution?

g) Suppose that the profit contribution of component 3 decrease by $2.00 . Would the optimal solution change

h) Is the problem degenerate? Explain!

i) Are there alternative optima in this problem? Explain

Trending now

This is a popular solution!

Step by step

Solved in 7 steps with 7 images