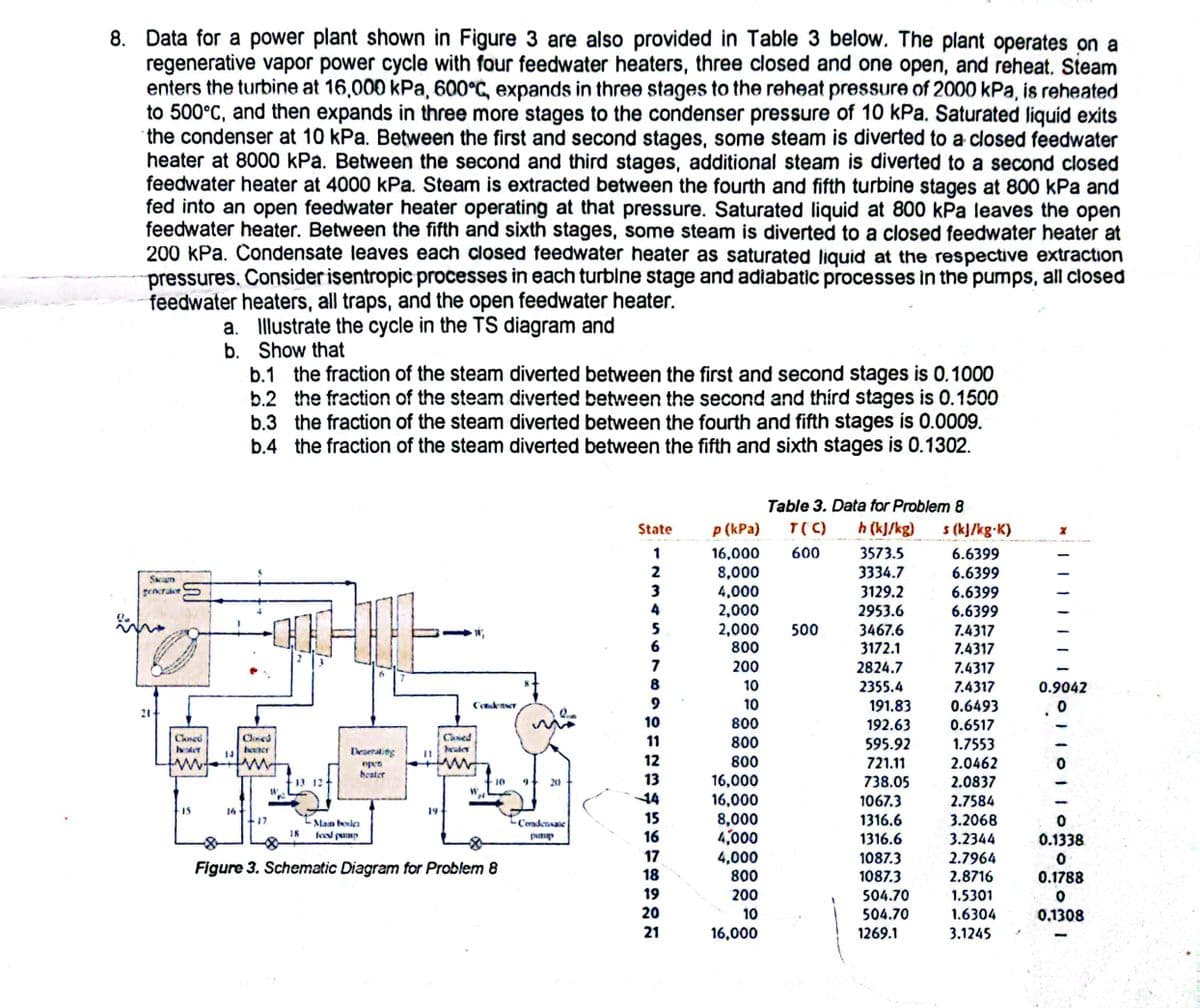

Data for a power plant shown in Figure 3 are also provided in Table 3 below. The plant operates on a regenerative vapor power cycle with four feedwater heaters, three closed and one open, and reheat. Steam enters the turbine at 16,000 kPa, 600°C, expands in three stages to the reheat pressure of 2000 kPa, is reheated to 500°C, and then expands in three more stages to the condenser pressure of 10 kPa. Saturated liquid exits the condenser at 10 kPa. Between the first and second stages, some steam is diverted to a closed feedwater heater at 8000 kPa. Between the second and third stages, additional steam is diverted to a second closed feedwater heater at 4000 kPa. Steam is extracted between the fourth and fifth turbine stages at 800 kPa and fed into an open feedwater heater operating at that pressure. Saturated liquid at 800 kPa leaves the open feedwater heater. Between the fifth and sixth stages, some steam is diverted to a closed feedwater heater at 200 kPa. Condensate leaves each closed feedwater heater as saturated liquid at the respective extraction pressures. Consider isentropic processes in each turbine stage and adiabatic processes in the pumps, all closed feedwater heaters, all traps, and the open feedwater heater. a. Illustrate the cycle in the TS diagram and

Data for a power plant shown in Figure 3 are also provided in Table 3 below. The plant operates on a regenerative vapor power cycle with four feedwater heaters, three closed and one open, and reheat. Steam enters the turbine at 16,000 kPa, 600°C, expands in three stages to the reheat pressure of 2000 kPa, is reheated to 500°C, and then expands in three more stages to the condenser pressure of 10 kPa. Saturated liquid exits the condenser at 10 kPa. Between the first and second stages, some steam is diverted to a closed feedwater heater at 8000 kPa. Between the second and third stages, additional steam is diverted to a second closed feedwater heater at 4000 kPa. Steam is extracted between the fourth and fifth turbine stages at 800 kPa and fed into an open feedwater heater operating at that pressure. Saturated liquid at 800 kPa leaves the open feedwater heater. Between the fifth and sixth stages, some steam is diverted to a closed feedwater heater at 200 kPa. Condensate leaves each closed feedwater heater as saturated liquid at the respective extraction pressures. Consider isentropic processes in each turbine stage and adiabatic processes in the pumps, all closed feedwater heaters, all traps, and the open feedwater heater. a. Illustrate the cycle in the TS diagram and

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

Please give only the ts diagram

Transcribed Image Text:8. Data for a power plant shown in Figure 3 are also provided in Table 3 below. The plant operates on a

regenerative vapor power cycle with four feedwater heaters, three closed and one open, and reheat. Steam

enters the turbine at 16,000 kPa, 600°C, expands in three stages to the reheat pressure of 2000 kPa, is reheated

to 500°C, and then expands in three more stages to the condenser pressure of 10 kPa. Saturated liquid exits

the condenser at 10 kPa. Between the first and second stages, some steam is diverted to a closed feedwater

heater at 8000 kPa. Between the second and third stages, additional steam is diverted to a second closed

feedwater heater at 4000 kPa. Steam is extracted between the fourth and fifth turbine stages at 800 kPa and

fed into an open feedwater heater operating at that pressure. Saturated liquid at 800 kPa leaves the open

feedwater heater. Between the fifth and sixth stages, some steam is diverted to a closed feedwater heater at

200 kPa. Condensate leaves each closed feedwater heater as saturated liquid at the respective extraction

pressures. Consider isentropic processes in each turbine stage and adiabatic processes in the pumps, all closed

feedwater heaters, all traps, and the open feedwater heater.

a. Illustrate the cycle in the TS diagram and

b.

Show that

Seam

generaler

21-

Closed

15

16

L"

b.1 the fraction of the steam diverted between the first and second stages is 0.1000

b.2 the fraction of the steam diverted between the second and third stages is 0.1500

the fraction of the steam diverted between the fourth and fifth stages is 0.0009.

the fraction of the steam diverted between the fifth and sixth stages is 0.1302.

b.3

b.4

Cloned

bouter

17

18

Deserating

open

beater

Main boric

feed pump

19

Caned

W₁

Condenser

10

Figure 3. Schematic Diagram for Problem 8

8

20

-Condensate

party

State

1234567

8

9

10

11

12

13

14

15

16

17

18

19

20

21

Table 3. Data for Problem 8

p (kPa) T(C) h (kJ/kg) s (kJ/kg-K)

16,000 600

8,000

4,000

2,000

2,000 500

800

200

10

10

800

800

800

16,000

16,000

8,000

4,000

4,000

800

200

10

16,000

3573.5

3334.7

3129.2

2953.6

3467.6

3172.1

2824.7

2355.4

191.83

192.63

595.92

721.11

738.05

1067.3

1316.6

1316.6

1087.3

1087.3

504.70

504.70

1269.1

6.6399

6.6399

6.6399

6.6399

7.4317

7.4317

7.4317

7.4317

0.6493

0.6517

1.7553

2.0462

2.0837

2.7584

3.2068

3.2344

2.7964

2.8716

1.5301

1.6304

3.1245

0.9042

.0

0

0.1338

0

0.1788

0

0.1308

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY