Design Problem: You nave just been hired as a Controf Systems Integrator. Your first project is for a client who wishes to retrofit (modernize) an industrial wash unit. The current system utilizes a mechanical drum sequencer type motorized mechanical timing device. Based on what you have learned in TEC 263, you know that a PLC would be a perfect solution to this problem! The customer is willing to replace or "rewire" I/O as necessary (e.g. switches, button, sensors, etc.) but, the process must remain the same. Since you decided to use a PLC, you now have the ability to provide a few enhancements! So, the customer also requests that the number of completed wash cycles is tracked and displayed (something that was not being done before). Using the following industrial electrical (wiring/ relay) ladder diagram and the corresponding functionality chart, design a PLC system (ladder logic

Design Problem: You nave just been hired as a Controf Systems Integrator. Your first project is for a client who wishes to retrofit (modernize) an industrial wash unit. The current system utilizes a mechanical drum sequencer type motorized mechanical timing device. Based on what you have learned in TEC 263, you know that a PLC would be a perfect solution to this problem! The customer is willing to replace or "rewire" I/O as necessary (e.g. switches, button, sensors, etc.) but, the process must remain the same. Since you decided to use a PLC, you now have the ability to provide a few enhancements! So, the customer also requests that the number of completed wash cycles is tracked and displayed (something that was not being done before). Using the following industrial electrical (wiring/ relay) ladder diagram and the corresponding functionality chart, design a PLC system (ladder logic

Computer Networking: A Top-Down Approach (7th Edition)

7th Edition

ISBN:9780133594140

Author:James Kurose, Keith Ross

Publisher:James Kurose, Keith Ross

Chapter1: Computer Networks And The Internet

Section: Chapter Questions

Problem R1RQ: What is the difference between a host and an end system? List several different types of end...

Related questions

Question

Using THE APP CODESYS, make A LADDER LOGIC FOR THIS PROGRAM . Need a PLC PROGRAM NOT A DEFINITION.

This wasn’t answered the right way! Last time I put it up.

Transcribed Image Text:İndustrial Wash Unit Retrofit Project

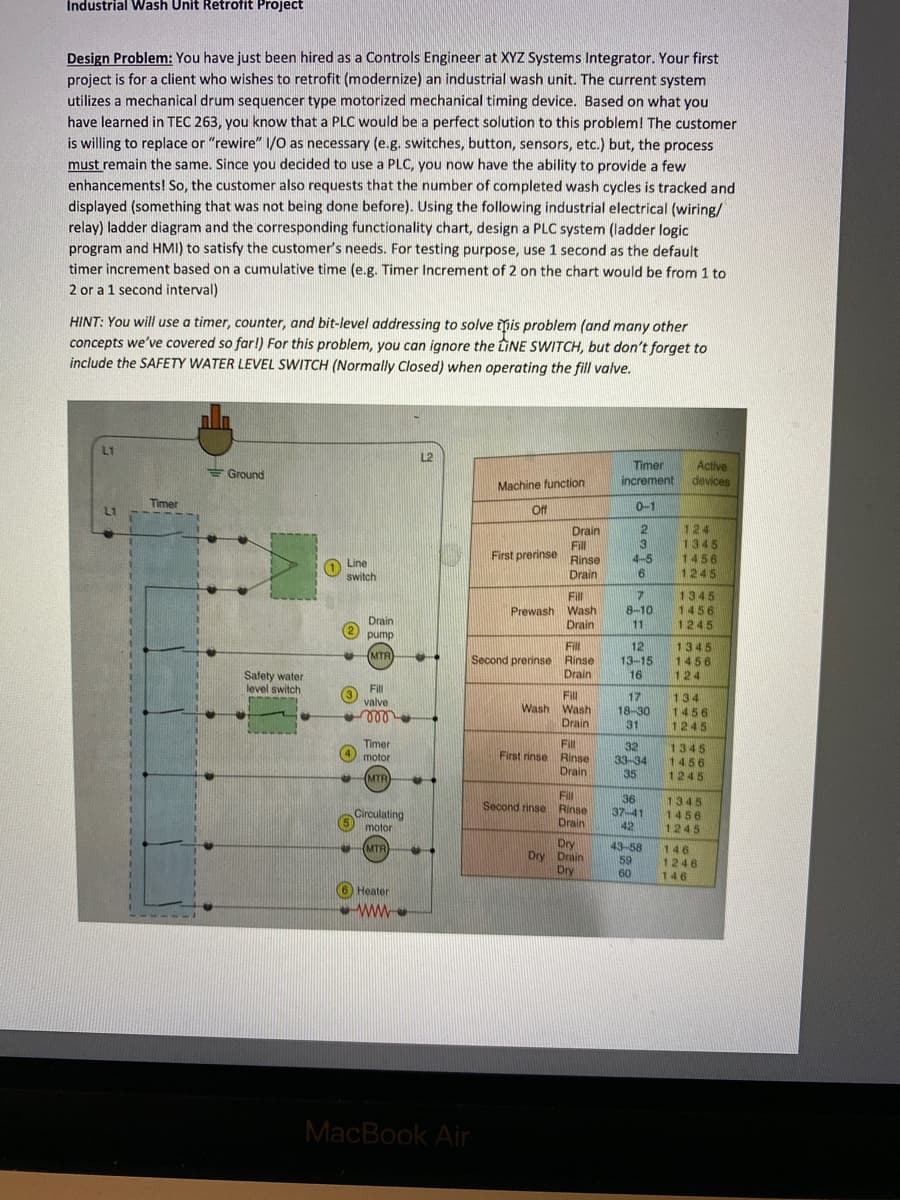

Design Problem: You have just been hired as a Controls Engineer at XYZ Systems Integrator. Your first

project is for a client who wishes to retrofit (modernize) an industrial wash unit. The current system

utilizes a mechanical drum sequencer type motorized mechanical timing device. Based on what you

have learned in TEC 263, you know that a PLC would be a perfect solution to this problem! The customer

is willing to replace or "rewire" I/0 as necessary (e.g. switches, button, sensors, etc.) but, the process

must remain the same. Since you decided to use a PLC, you now have the ability to provide a few

enhancements! So, the customer also requests that the number of completed wash cycles is tracked and

displayed (something that was not being done before). Using the following industrial electrical (wiring/

relay) ladder diagram and the corresponding functionality chart, design a PLC system (ladder logic

program and HMI) to satisfy the customer's needs. For testing purpose, use 1 second as the default

timer increment based on a cumulative time (e.g. Timer Increment of 2 on the chart would be from 1 to

2 or a 1 second interval)

HINT: You will use a timer, counter, and bit-level addressing to solve ipis problem (and many other

concepts we've covered so far!) For this problem, you can ignore the LINE SWITCH, but don't forget to

include the SAFETY WATER LEVEL SWITCH (Normally Closed) when operating the fill valve.

L1

L2

Timer

increment

Active

devices

E Ground

Machine function

Timer

0-1

L1

ff

12

Drain

Fill

First prerinse Rinse

124

1345

1456

1245

4-5

O Line

switch

Drain

1345

1456

1245

Fill

8-10

Prewash Wash

Drain

Drain

2 pump

dwnd

(MTR

11

Fill

Second prerinse Rinse

Drain

1345

1456

124

12

%24

13-15

16

Safety water

level switch

Fill

(3

valve

Fill

Wash Wash

17

18-30

31

134

1456

1245

Drain

Timer

Fill

First rinse Rinse

32

33-34

35

1345

O motor

1456

1245

Drain

(MTR

Fill

Second rinse Rinse

36

37-41

42

1345

1456

1245

Circulating

Drain

motor

Dry

Dry Drain

Dry

43-58

59

60

(MTR

146

1246

146

Heater

wW.

MacBook Air

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps with 1 images

Recommended textbooks for you

Computer Networking: A Top-Down Approach (7th Edi…

Computer Engineering

ISBN:

9780133594140

Author:

James Kurose, Keith Ross

Publisher:

PEARSON

Computer Organization and Design MIPS Edition, Fi…

Computer Engineering

ISBN:

9780124077263

Author:

David A. Patterson, John L. Hennessy

Publisher:

Elsevier Science

Network+ Guide to Networks (MindTap Course List)

Computer Engineering

ISBN:

9781337569330

Author:

Jill West, Tamara Dean, Jean Andrews

Publisher:

Cengage Learning

Computer Networking: A Top-Down Approach (7th Edi…

Computer Engineering

ISBN:

9780133594140

Author:

James Kurose, Keith Ross

Publisher:

PEARSON

Computer Organization and Design MIPS Edition, Fi…

Computer Engineering

ISBN:

9780124077263

Author:

David A. Patterson, John L. Hennessy

Publisher:

Elsevier Science

Network+ Guide to Networks (MindTap Course List)

Computer Engineering

ISBN:

9781337569330

Author:

Jill West, Tamara Dean, Jean Andrews

Publisher:

Cengage Learning

Concepts of Database Management

Computer Engineering

ISBN:

9781337093422

Author:

Joy L. Starks, Philip J. Pratt, Mary Z. Last

Publisher:

Cengage Learning

Prelude to Programming

Computer Engineering

ISBN:

9780133750423

Author:

VENIT, Stewart

Publisher:

Pearson Education

Sc Business Data Communications and Networking, T…

Computer Engineering

ISBN:

9781119368830

Author:

FITZGERALD

Publisher:

WILEY