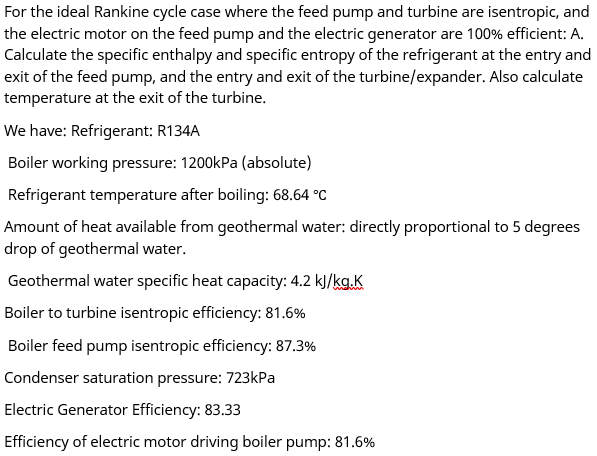

For the ideal Rankine cycle case where the feed pump and turbine are isentropic, and the electric motor on the feed pump and the electric generator are 100% efficient: A. Calculate the specific enthalpy and specific entropy of the refrigerant at the entry and exit of the feed pump, and the entry and exit of the turbine/expander. Also calculate temperature at the exit of the turbine. We have: Refrigerant: R134A Boiler working pressure: 1200kPa (absolute) Refrigerant temperature after boiling: 68.64 °C Amount of heat available from geothermal water: directly proportional to 5 degrees drop of geothermal water. Geothermal water specific heat capacity: 4.2 kJ/kg.k

Step by step

Solved in 3 steps with 4 images

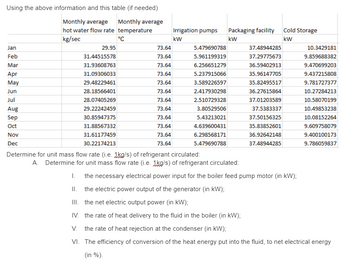

Using that information and this table

For the average monthly rate of geothermal heat available, determine, for the real case: in a tabular format and show sample calculation for one month.

- the necessary monthly average mass flow rate (in kg/s) of the refrigerant that must be pumped through the heat exchanger to collect the thermal energy from the available geothermal hot water flow rate if the hot water was cooled by 5°C. What should be the flow capacity (in kg/s) of feed pump of the ORC heat engine that you are designing and the monthly average net electric power generation capacity (in kW).

2. the monthly average net electric power generation capacity (in kW) and yearly average net electrical power generation capacity (in kW).

I want a step by step working out on how all these values were obtained and what table was used

Considering now the real case, where the turbine and feed pump are not isentropic, and the feed pump electric motor and the electric generator are not 100% efficient:

- Calculate the actual specific enthalpy and actual specific entropy and the actual temperature of the refrigerant at the exit of the feed pump, and the exit of the turbine/expander;

What if the turbine and feed pump are not isentropic what would be the actual specific enthalpy and actual specific entropy and the actual temperature of the refrigerant at the exit of the feed pump, and the exit of the turbine/expander.

could u give me a brief explanation on how to read the table of r134A as well?