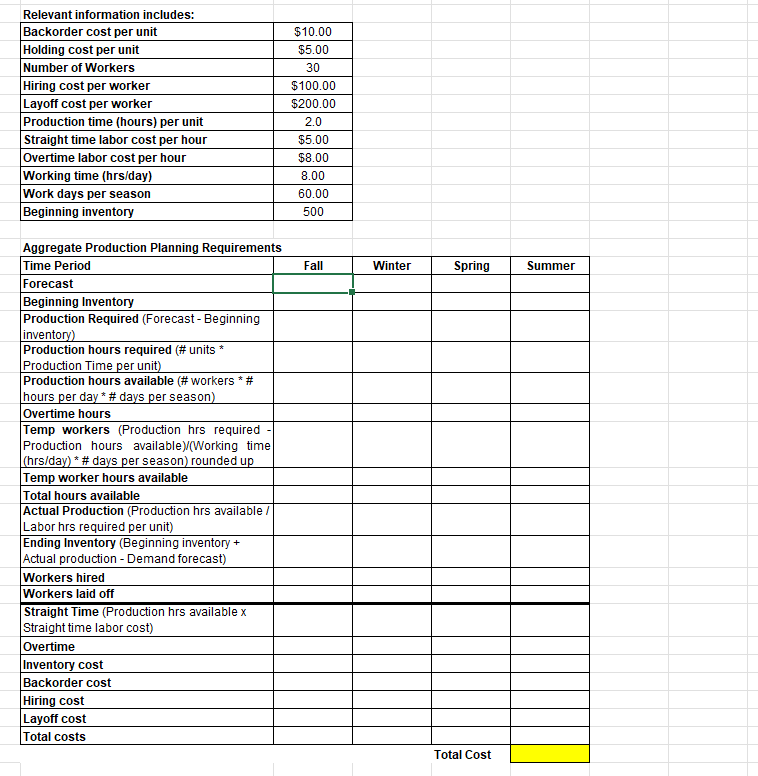

Develop a production plan and calculate the annual cost for a firm whose demand forecast is fall, 11,000; winter, 8,000; spring, 6,000; summer, 13,000. Inventory at the beginning of fall is 500 units. At the beginning of fall you currently have 30 workers, but you plan to hire temporary workers at the beginning of summer and lay them off at the end of summer. In addition, you have negotiated with the union an option to use the regular workforce on overtim

Develop a production plan and calculate the annual cost for a firm whose demand

a. What is the total cost for this plan?

Trending now

This is a popular solution!

Step by step

Solved in 4 steps with 6 images