eprint to print an object la cells and biomaterials, crea

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

Please solve complete

Transcribed Image Text:A

Compressed air

3-axis robotic

Temperature sensor

Heatable syringe

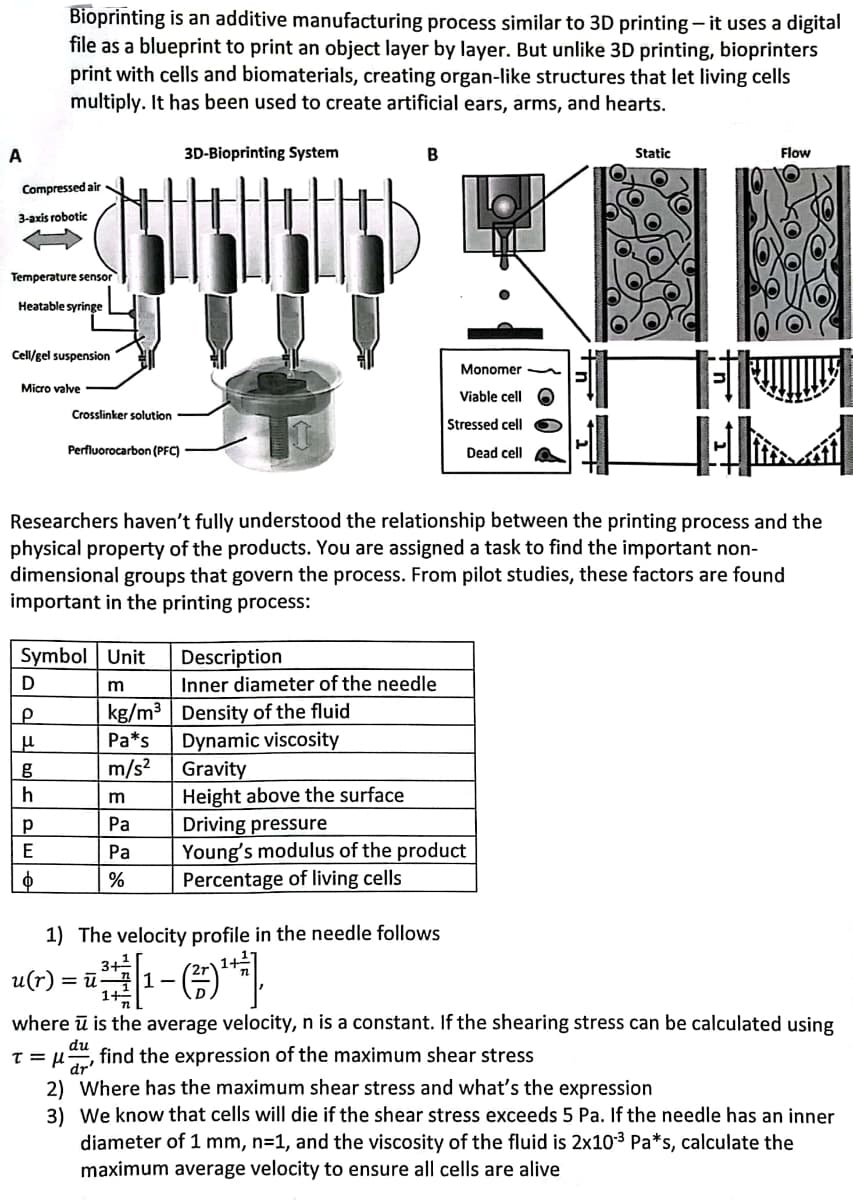

Bioprinting is an additive manufacturing process similar to 3D printing - it uses a digital

file as a blueprint to print an object layer by layer. But unlike 3D printing, bioprinters

print with cells and biomaterials, creating organ-like structures that let living cells

multiply. It has been used to create artificial ears, arms, and hearts.

3D-Bioprinting System

Cell/gel suspension

Micro valve

D

P

|__μ

g

h

Р

Crosslinker solution

Symbol Unit

m

kg/m³ Density of the fluid

Pa*s Dynamic viscosity

Gravity

m/s²

E

Ф

Perfluorocarbon (PFC)

4 HE

Researchers haven't fully understood the relationship between the printing process and the

physical property of the products. You are assigned a task to find the important non-

dimensional groups that govern the process. From pilot studies, these factors are found

important in the printing process:

m

Pa

Pa

%

B

3+²

=ū-11-

Description

Inner diameter of the needle

Height above the surface

Monomer

Viable cell

Stressed cell

Dead cell

1) The velocity profile in the needle follows

-(¹)

Driving pressure

Young's modulus of the product

Percentage of living cells

Static

Flow

u(r)

where ū is the average velocity, n is a constant. If the shearing stress can be calculated using

du

T = μ find the expression of the maximum shear stress

dr'

2)

Where has the maximum shear stress and what's the expression

3) We know that cells will die if the shear stress exceeds 5 Pa. If the needle has an inner

diameter of 1 mm, n=1, and the viscosity of the fluid is 2x10-³ Pa*s, calculate the

maximum average velocity to ensure all cells are alive

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 4 steps with 4 images

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The