a B P b X

Refrigeration and Air Conditioning Technology (MindTap Course List)

8th Edition

ISBN:9781305578296

Author:John Tomczyk, Eugene Silberstein, Bill Whitman, Bill Johnson

Publisher:John Tomczyk, Eugene Silberstein, Bill Whitman, Bill Johnson

Chapter29: Troubleshooting And Typical Operating Conditions For Commercial refrigeration

Section: Chapter Questions

Problem 16RQ

Related questions

Question

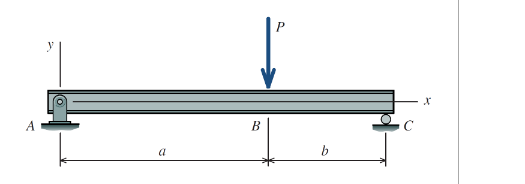

A simply supported steel universal I shaped beam is shown(see attached table and choose one size)

The total length is 15 meters with a concentrated force P (located at a distance a = 10 meters) created by a mass of 2000 kg. By assuming a yield strength of 350 MPa and a safety factor of 3.2 state the ergonomically suitable nominal beam size from the catalogue.

With reference to answer describe the type of beam failure and at least one possible consequence if the I-beam size you selected is too small.

You may add additional images for illustration purposes but ensure that (a) it is described properly, and (b) it is relevant.

Transcribed Image Text:A

a

B

b

с

X

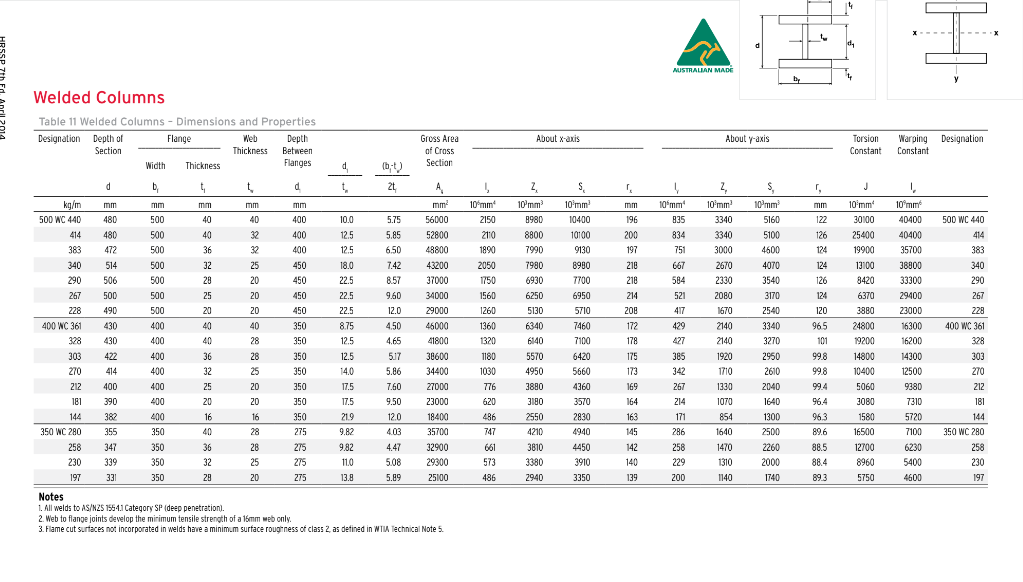

Transcribed Image Text:Welded Columns

Table 11 Welded Columns - Dimensions and Properties

Designation Depth of

Flange

Section

kg/m

500 WC 440

d

mm

480

414

480

383

472

340 514

290 506

267 500

228

490

400 WC 361

430

328

430

303

422

270 414

212 400

181

390

144

350 WC 280

258

230

197

382

355

347

339

331

Width

b₁

mm

500

500

500

500

500

500

500

400

400

400

400

400

400

400

350

350

350

350

Thickness

t₁

mm

40

40

36

32

28

25

20

40

40

36

32

25

20

20

16

40

36

32

28

Web Depth

Thickness Between

Flanges

t

mm

40

32

32

25

20

20

20

40

28

28

25

20

20

16

28

28

25

20

d

חוד

400

400

400

450

450

450

450

350

350

350

350

350

350

350

275

275

275

275

le

d.

t

10.0

12.5

12.5

18.0

22.5

22.5

22.5

8.75

12.5

12.5

14.0

17.5

17.5

21.9

9.82

9.82

11.0

13.8

(bit)

2t,

5.75

5.85

6.50

7.42

8.57

9.60

12.0

4.50

4.65

5.17

5.86

7.60

9.50

12.0

4.03

Gross Area

of Cross

Section

A,

mm²

56000

52800

48800

43200

37000

34000

29000

46000

41800

38600

34400

27000

23000

18400

35700

4.47 32900

5.08

29300

5.89

25100

Notes

1. All welds to AS/NZS 1554.1 Category SP (deep penetration).

2. Web to flange joints develop the minimum tensile strength of a 16mm web only.

3. Flame cut surfaces not incorporated in welds have a minimum surface roughness of class 2, as defined in WTIA Technical Note 5.

L

10 mm

2150

2110

1890

2050

1750

1560

1260

1360

1320

1180

1030

776

620

486

747

661

573

486

About x-axis

2,

10mm

8980

8800

7990

7980

6930

6250

5130

6340

6140

5570

4950

3880

3180

2550

4210

3810

3380

2940

S₁

10³mm³

10400

10100

9130

8980

7700

6950

5710

7460

7100

6420

5660

4360

3570

2830

4940

4450

3910

3350

ņ

mm

196

200

197

218

218

214

208

172

178

175

173

169

164

163

145

142

140

139

AUSTRALIAN MADE

I

105mm

835

834

751

667

584

521

417

429

427

385

342

267

214

171

286

258

229

200

About y-axis

2, S₁

10³mm³ 10³mm

3340

5160

3340 5100

4600

3000

2670

4070

3540

2330

2080

1670

2140

2140

1920

1710

1411

1330

1070

854

1640

1470

1310

1140

3170

2540

3340

3270

2950

2610

2040

1640

1300

2500

2260

2000

1740

by

(₂

mm

122

126

124

124

126

124

120

96.5

101

99.8

99.8

99.4

96.4

96.3

89.6

88.5

88.4

89.3

Torsion Warping

Constant Constant

J

10³mm

30100

10 mm

40400

40400

19900 35700

25400

13100 38800

8420

6370

3880

24800

33300

29400

23000

16300

19200

16200

14800

14300

10400

12500

9380

7310

5720

7100

6230

5400

4600

5060

3080

1580

16500

H

12700

8960

5750

Designation

500 WC 440

414

383

340

290

267

261

228

400 WC 361

328

303

270

212

181

144

350 WC 280

258

230

197

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 3 steps with 2 images

Follow-up Questions

Read through expert solutions to related follow-up questions below.

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Refrigeration and Air Conditioning Technology (Mi…

Mechanical Engineering

ISBN:

9781305578296

Author:

John Tomczyk, Eugene Silberstein, Bill Whitman, Bill Johnson

Publisher:

Cengage Learning

Refrigeration and Air Conditioning Technology (Mi…

Mechanical Engineering

ISBN:

9781305578296

Author:

John Tomczyk, Eugene Silberstein, Bill Whitman, Bill Johnson

Publisher:

Cengage Learning