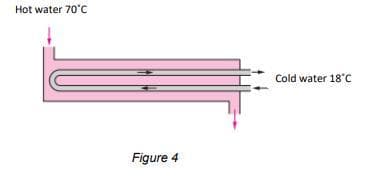

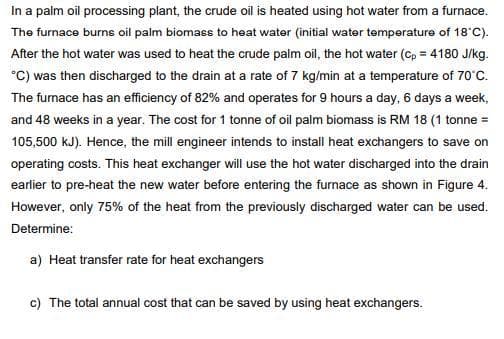

In a palm oil processing plant, the crude oil is heated using hot water from a furnace. The furnace burns oil palm biomass to heat water (initial water temperature of 18'C). After the hot water was used to heat the crude palm oil, the hot water (Cp = 4180 J/kg. "C) was then discharged to the drain at a rate of 7 kg/min at a temperature of 70°C. The furnace has an efficiency of 82% and operates for 9 hours a day, 6 days a week, and 48 weeks in a year. The cost for 1 tonne of oil palm biomass is RM 18 (1 tonne = 105,500 kJ). Hence, the mill engineer intends to install heat exchangers to save on operating costs. This heat exchanger will use the hot water discharged into the drain earlier to pre-heat the new water before entering the furnace as shown in Figure 4. However, only 75% of the heat from the previously discharged water can be used. Determine: a) Heat transfer rate for heat exchangers c) The total annual cost that can be saved by using heat exchangers.

In a palm oil processing plant, the crude oil is heated using hot water from a furnace. The furnace burns oil palm biomass to heat water (initial water temperature of 18'C). After the hot water was used to heat the crude palm oil, the hot water (Cp = 4180 J/kg. "C) was then discharged to the drain at a rate of 7 kg/min at a temperature of 70°C. The furnace has an efficiency of 82% and operates for 9 hours a day, 6 days a week, and 48 weeks in a year. The cost for 1 tonne of oil palm biomass is RM 18 (1 tonne = 105,500 kJ). Hence, the mill engineer intends to install heat exchangers to save on operating costs. This heat exchanger will use the hot water discharged into the drain earlier to pre-heat the new water before entering the furnace as shown in Figure 4. However, only 75% of the heat from the previously discharged water can be used. Determine: a) Heat transfer rate for heat exchangers c) The total annual cost that can be saved by using heat exchangers.

Refrigeration and Air Conditioning Technology (MindTap Course List)

8th Edition

ISBN:9781305578296

Author:John Tomczyk, Eugene Silberstein, Bill Whitman, Bill Johnson

Publisher:John Tomczyk, Eugene Silberstein, Bill Whitman, Bill Johnson

Chapter33: Hydronic Heat

Section: Chapter Questions

Problem 13RQ: True or False: City water does not contain air.

Related questions

Question

Please fast solve the issue

Transcribed Image Text:Hot water 70'C

Cold water 18°C

Figure 4

Transcribed Image Text:In a palm oil processing plant, the crude oil is heated using hot water from a furnace.

The furnace burns oil palm biomass to heat water (initial water temperature of 18*'C).

After the hot water was used to heat the crude palm oil, the hot water (cp = 4180 J/kg.

°C) was then discharged to the drain at a rate of 7 kg/min at a temperature of 70°c.

The funace has an efficiency of 82% and operates for 9 hours a day, 6 days a week,

and 48 weeks in a year. The cost for 1 tonne of oil palm biomass is RM 18 (1 tonne =

105,500 kJ). Hence, the mill engineer intends to install heat exchangers to save on

operating costs. This heat exchanger will use the hot water discharged into the drain

earlier to pre-heat the new water before entering the furnace as shown in Figure 4.

However, only 75% of the heat from the previously discharged water can be used.

Determine:

a) Heat transfer rate for heat exchangers

c) The total annual cost that can be saved by using heat exchangers.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Refrigeration and Air Conditioning Technology (Mi…

Mechanical Engineering

ISBN:

9781305578296

Author:

John Tomczyk, Eugene Silberstein, Bill Whitman, Bill Johnson

Publisher:

Cengage Learning

Automotive Technology: A Systems Approach (MindTa…

Mechanical Engineering

ISBN:

9781133612315

Author:

Jack Erjavec, Rob Thompson

Publisher:

Cengage Learning

Refrigeration and Air Conditioning Technology (Mi…

Mechanical Engineering

ISBN:

9781305578296

Author:

John Tomczyk, Eugene Silberstein, Bill Whitman, Bill Johnson

Publisher:

Cengage Learning

Automotive Technology: A Systems Approach (MindTa…

Mechanical Engineering

ISBN:

9781133612315

Author:

Jack Erjavec, Rob Thompson

Publisher:

Cengage Learning