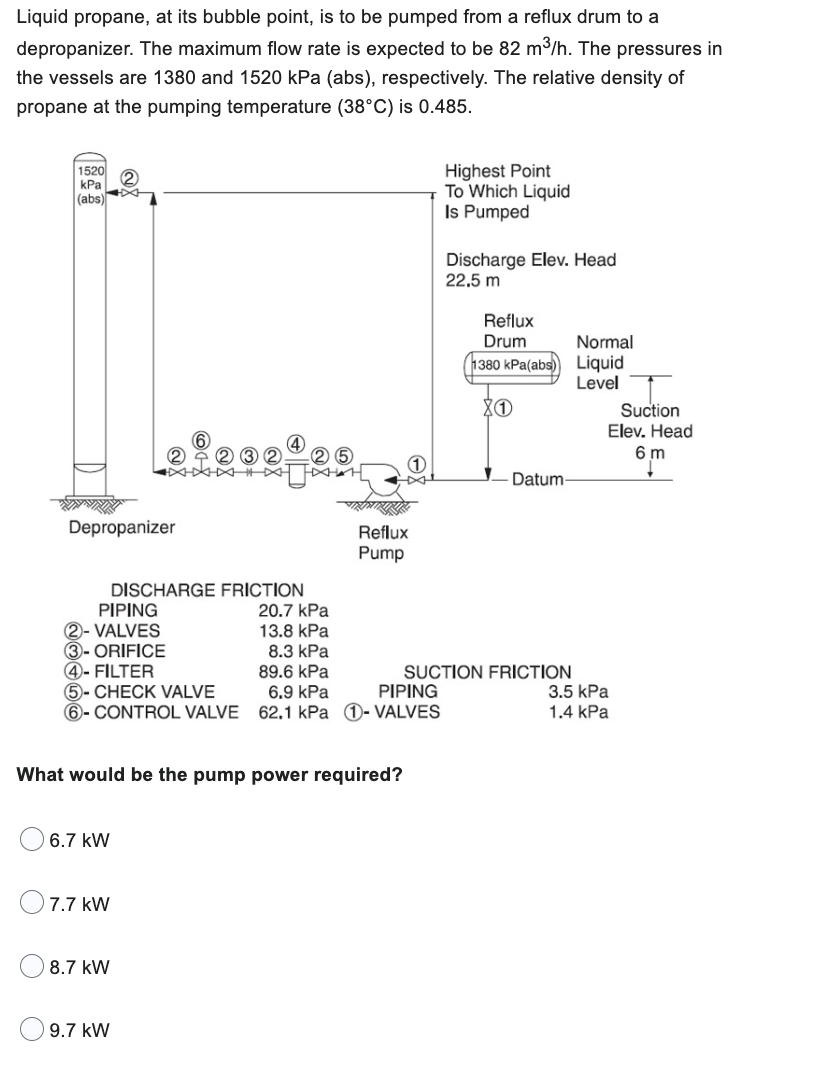

Liquid propane, at its bubble point, is to be pumped from a reflux drum to a depropanizer. The maximum flow rate is expected to be 82 m³/h. The pressures in the vessels are 1380 and 1520 kPa (abs), respectively. The relative density of propane at the pumping temperature (38°C) is 0.485. 1520 2 kPa (abs) Highest Point To Which Liquid Is Pumped Discharge Elev. Head 22.5 m Reflux Drum Normal 1380 kPa(abs) Liquid Level 81 Suction Elev. Head 6 m Datum- Depropanizer Reflux Pump DISCHARGE FRICTION PIPING 2- VALVES 20.7 kPa 13.8 kPa 3- ORIFICE 8.3 kPa 4- FILTER 89.6 kPa SUCTION FRICTION 5-CHECK VALVE PIPING 6-CONTROL VALVE 62.1 kPa ①- VALVES 6.9 kPa 3.5 kPa 1.4 kPa What would be the pump power required? 6.7 kW 7.7 kW 8.7 kW 9.7 kW

Liquid propane, at its bubble point, is to be pumped from a reflux drum to a depropanizer. The maximum flow rate is expected to be 82 m³/h. The pressures in the vessels are 1380 and 1520 kPa (abs), respectively. The relative density of propane at the pumping temperature (38°C) is 0.485. 1520 2 kPa (abs) Highest Point To Which Liquid Is Pumped Discharge Elev. Head 22.5 m Reflux Drum Normal 1380 kPa(abs) Liquid Level 81 Suction Elev. Head 6 m Datum- Depropanizer Reflux Pump DISCHARGE FRICTION PIPING 2- VALVES 20.7 kPa 13.8 kPa 3- ORIFICE 8.3 kPa 4- FILTER 89.6 kPa SUCTION FRICTION 5-CHECK VALVE PIPING 6-CONTROL VALVE 62.1 kPa ①- VALVES 6.9 kPa 3.5 kPa 1.4 kPa What would be the pump power required? 6.7 kW 7.7 kW 8.7 kW 9.7 kW

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

y

Transcribed Image Text:Liquid propane, at its bubble point, is to be pumped from a reflux drum to a

depropanizer. The maximum flow rate is expected to be 82 m³/h. The pressures in

the vessels are 1380 and 1520 kPa (abs), respectively. The relative density of

propane at the pumping temperature (38°C) is 0.485.

1520

kPa

(abs)

Depropanizer

PIPING

2- VALVES

3- ORIFICE

4-FILTER

5-CHECK VALVE

8.3 kPa

89.6 kPa

6.9 kPa

6- CONTROL VALVE 62.1 kPa

6.7 kW

DISCHARGE FRICTION

7.7 kW

8.7 kW

20.7 kPa

13.8 kPa

What would be the pump power required?

9.7 kW

Reflux

Pump

PIPING

1-VALVES

Highest Point

To Which Liquid

Is Pumped

Discharge Elev. Head

22.5 m

Reflux

Drum

Normal

1380 kPa (abs) Liquid

Level

Datum

SUCTION FRICTION

Suction

Elev. Head

6m

3.5 kPa

1.4 kPa

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 4 steps with 4 images

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The