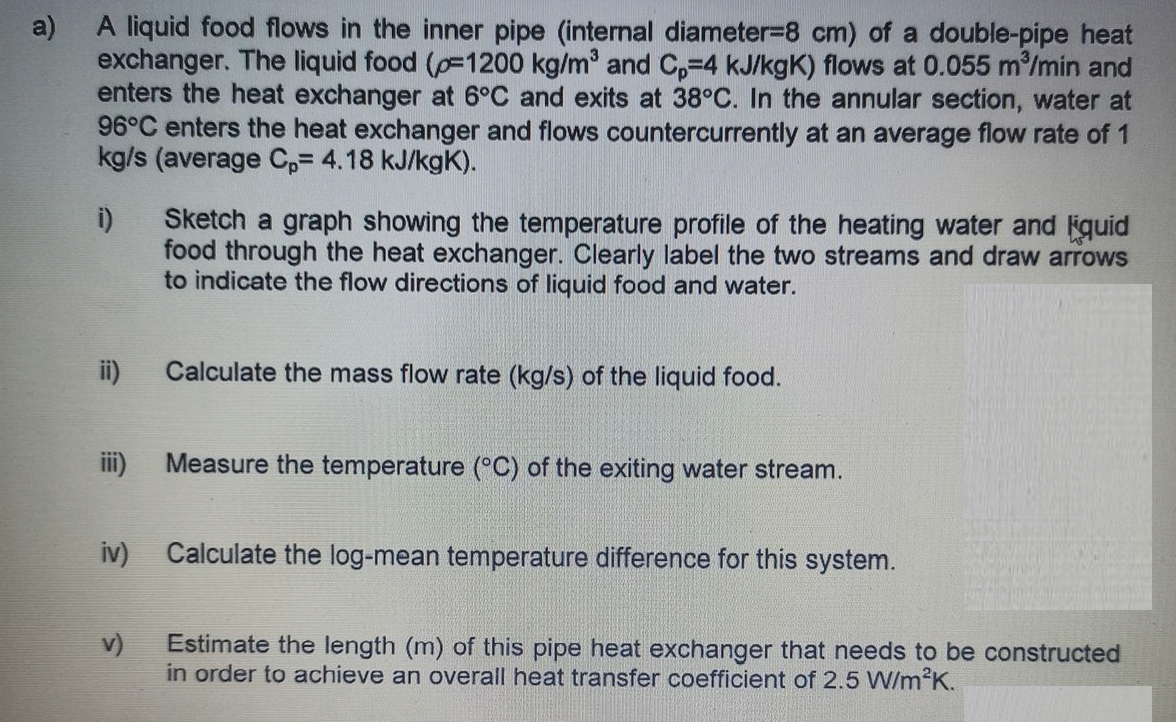

A liquid food flows in the inner pipe (internal diameter-8 cm) of a double-pipe heat exchanger. The liquid food (p=1200 kg/m and C,-4 kJ/kgK) flows at 0.055 m/min and enters the heat exchanger at 6°C and exits at 38°C. In the annular section, water at 96°C enters the heat exchanger and flows countercurrently at an average flow rate of 1 kg/s (average Cp= 4.18 kJ/kgK). a) Sketch a graph showing the temperature profile of the heating water and quid food through the heat exchanger. Clearly label the two streams and draw arrows to indicate the flow directions of liquid food and water. i) ii) Calculate the mass flow rate (kg/s) of the liquid food. ii) Me sure the temperature (°C) of the exiting water stream. iv) Calculate the log-mean temperature difference for this system. Estimate the length (m) of this pipe heat exchanger that needs to be constructed in order to achieve an overall heat transfer coefficient of 2.5 W/m2K.

A liquid food flows in the inner pipe (internal diameter-8 cm) of a double-pipe heat exchanger. The liquid food (p=1200 kg/m and C,-4 kJ/kgK) flows at 0.055 m/min and enters the heat exchanger at 6°C and exits at 38°C. In the annular section, water at 96°C enters the heat exchanger and flows countercurrently at an average flow rate of 1 kg/s (average Cp= 4.18 kJ/kgK). a) Sketch a graph showing the temperature profile of the heating water and quid food through the heat exchanger. Clearly label the two streams and draw arrows to indicate the flow directions of liquid food and water. i) ii) Calculate the mass flow rate (kg/s) of the liquid food. ii) Me sure the temperature (°C) of the exiting water stream. iv) Calculate the log-mean temperature difference for this system. Estimate the length (m) of this pipe heat exchanger that needs to be constructed in order to achieve an overall heat transfer coefficient of 2.5 W/m2K.

Principles of Heat Transfer (Activate Learning with these NEW titles from Engineering!)

8th Edition

ISBN:9781305387102

Author:Kreith, Frank; Manglik, Raj M.

Publisher:Kreith, Frank; Manglik, Raj M.

Chapter7: Forced Convection Inside Tubes And Ducts

Section: Chapter Questions

Problem 7.46P

Related questions

Concept explainers

Heat Exchangers

Heat exchangers are the types of equipment that are primarily employed to transfer the thermal energy from one fluid to another, provided that one of the fluids should be at a higher thermal energy content than the other fluid.

Heat Exchanger

The heat exchanger is a combination of two words ''Heat'' and ''Exchanger''. It is a mechanical device that is used to exchange heat energy between two fluids.

Question

100%

Transcribed Image Text:A liquid food flows in the inner pipe (internal diameter-8 cm) of a double-pipe heat

exchanger. The liquid food (p=1200 kg/m and C,-4 kJ/kgK) flows at 0.055 m/min and

enters the heat exchanger at 6°C and exits at 38°C. In the annular section, water at

96°C enters the heat exchanger and flows countercurrently at an average flow rate of 1

kg/s (average Cp= 4.18 kJ/kgK).

a)

Sketch a graph showing the temperature profile of the heating water and quid

food through the heat exchanger. Clearly label the two streams and draw arrows

to indicate the flow directions of liquid food and water.

i)

ii)

Calculate the mass flow rate (kg/s) of the liquid food.

ii)

Me

sure the temperature (°C) of the exiting water stream.

iv)

Calculate the log-mean temperature difference for this system.

Estimate the length (m) of this pipe heat exchanger that needs to be constructed

in order to achieve an overall heat transfer coefficient of 2.5 W/m2K.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 3 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Principles of Heat Transfer (Activate Learning wi…

Mechanical Engineering

ISBN:

9781305387102

Author:

Kreith, Frank; Manglik, Raj M.

Publisher:

Cengage Learning

Principles of Heat Transfer (Activate Learning wi…

Mechanical Engineering

ISBN:

9781305387102

Author:

Kreith, Frank; Manglik, Raj M.

Publisher:

Cengage Learning