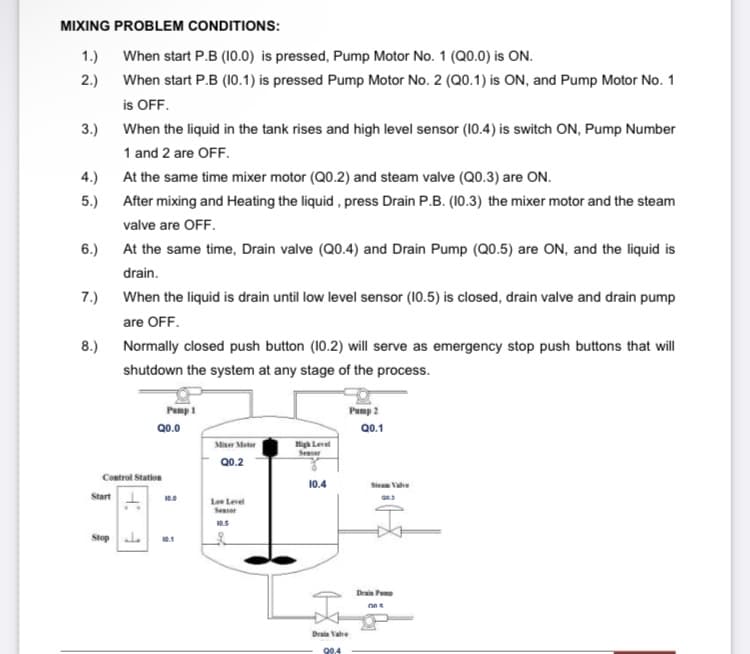

MIXING PROBLEM CONDITIONS: 1.) When start P.B (10.0) is pressed, Pump Motor No. 1 (Q0.0) is ON. 2.) When start P.B (10.1) is pressed Pump Motor No. 2 (Q0.1) is ON, and Pump Motor No. 1 is OFF. 3.) When the liquid in the tank rises and high level sensor (10.4) is switch ON, Pump Number 1 and 2 are OFF. 4.) At the same time mixer motor (Q0.2) and steam valve (Q0.3) are ON. 5.) After mixing and Heating the liquid , press Drain P.B. (10.3) the mixer motor and the steam valve are OFF,

MIXING PROBLEM CONDITIONS: 1.) When start P.B (10.0) is pressed, Pump Motor No. 1 (Q0.0) is ON. 2.) When start P.B (10.1) is pressed Pump Motor No. 2 (Q0.1) is ON, and Pump Motor No. 1 is OFF. 3.) When the liquid in the tank rises and high level sensor (10.4) is switch ON, Pump Number 1 and 2 are OFF. 4.) At the same time mixer motor (Q0.2) and steam valve (Q0.3) are ON. 5.) After mixing and Heating the liquid , press Drain P.B. (10.3) the mixer motor and the steam valve are OFF,

Principles of Heat Transfer (Activate Learning with these NEW titles from Engineering!)

8th Edition

ISBN:9781305387102

Author:Kreith, Frank; Manglik, Raj M.

Publisher:Kreith, Frank; Manglik, Raj M.

Chapter4: Numerical Analysis Of Heat Conduction

Section: Chapter Questions

Problem 4.4P

Related questions

Question

100%

Make a diagram.

Transcribed Image Text:MIXING PROBLEM CONDITIONS:

1.)

When start P.B (10.0) is pressed, Pump Motor No. 1 (Q0.0) is ON.

When start P.B (10.1) is pressed Pump Motor No. 2 (Q0.1) is ON, and Pump Motor No. 1

2.)

is OFF.

3.) When the liquid in the tank rises and high level sensor (10.4) is switch ON, Pump Number

1 and 2 are OFF.

4.) At the same time mixer motor (Q0.2) and steam valve (Q0.3) are ON.

5.) After mixing and Heating the liquid, press Drain P.B. (10.3) the mixer motor and the steam

valve are OFF.

6.) At the same time, Drain valve (Q0.4) and Drain Pump (Q0.5) are ON, and the liquid is

drain.

7.) When the liquid is drain until low level sensor (10.5) is closed, drain valve and drain pump

are OFF.

8.) Normally closed push button (I0.2) will serve as emergency stop push buttons that will

shutdown the system at any stage of the process.

Pump 1

Pump 2

Q0.0

Q0.1

Miser Moter

High Level

Seaser

Q0.2

Control Station

10.4

Sieam Vahe

Start

Le Level

Seser

Stop d.

0.1

Drain Pun

Draia Vahe

90.4

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Principles of Heat Transfer (Activate Learning wi…

Mechanical Engineering

ISBN:

9781305387102

Author:

Kreith, Frank; Manglik, Raj M.

Publisher:

Cengage Learning

Automotive Technology: A Systems Approach (MindTa…

Mechanical Engineering

ISBN:

9781133612315

Author:

Jack Erjavec, Rob Thompson

Publisher:

Cengage Learning

Principles of Heat Transfer (Activate Learning wi…

Mechanical Engineering

ISBN:

9781305387102

Author:

Kreith, Frank; Manglik, Raj M.

Publisher:

Cengage Learning

Automotive Technology: A Systems Approach (MindTa…

Mechanical Engineering

ISBN:

9781133612315

Author:

Jack Erjavec, Rob Thompson

Publisher:

Cengage Learning