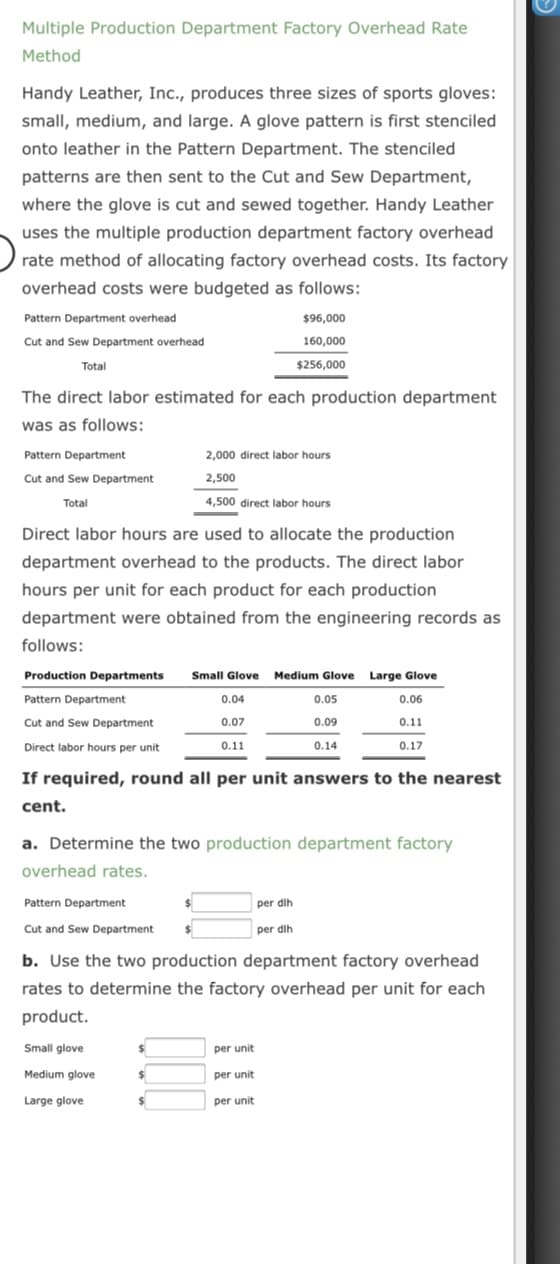

Multiple Production Department Factory Overhead Rate Method Handy Leather, Inc., produces three sizes of sports gloves: small, medium, and large. A glove pattern is first stenciled onto leather in the Pattern Department. The stenciled patterns are then sent to the Cut and Sew Department, where the glove is cut and sewed together. Handy Leather uses the multiple production department factory overhead rate method of allocating factory overhead costs. Its factory overhead costs were budgeted as follows: Pattern Department overhead $96,000 Cut and Sew Department overhead 160,000 Total $256,000 The direct labor estimated for each production department was as follows: Pattern Department 2,000 direct labor hours Cut and Sew Department 2,500 Total 4,500 direct labor hours Direct labor hours are used to allocate the production department overhead to the products. The direct labor hours per unit for each product for each production department were obtained from the engineering records as follows: Production Departments Small Glove Medium Glove Large Glove Pattern Department 0.04 0.05 0.06 Cut and Sew Department 0.07 0.09 0.11 Direct labor hours per unit 0.11 0.14 0.17 If required, round all per unit answers to the nearest cent. a. Determine the two production department factory overhead rates. Pattern Department per dih Cut and Sew Department per dih b. Use the two production department factory overhead rates to determine the factory overhead per unit for each product. Small glove per unit Medium glove %24 per unit Large glove 24 per unit

Multiple Production Department Factory Overhead Rate Method Handy Leather, Inc., produces three sizes of sports gloves: small, medium, and large. A glove pattern is first stenciled onto leather in the Pattern Department. The stenciled patterns are then sent to the Cut and Sew Department, where the glove is cut and sewed together. Handy Leather uses the multiple production department factory overhead rate method of allocating factory overhead costs. Its factory overhead costs were budgeted as follows: Pattern Department overhead $96,000 Cut and Sew Department overhead 160,000 Total $256,000 The direct labor estimated for each production department was as follows: Pattern Department 2,000 direct labor hours Cut and Sew Department 2,500 Total 4,500 direct labor hours Direct labor hours are used to allocate the production department overhead to the products. The direct labor hours per unit for each product for each production department were obtained from the engineering records as follows: Production Departments Small Glove Medium Glove Large Glove Pattern Department 0.04 0.05 0.06 Cut and Sew Department 0.07 0.09 0.11 Direct labor hours per unit 0.11 0.14 0.17 If required, round all per unit answers to the nearest cent. a. Determine the two production department factory overhead rates. Pattern Department per dih Cut and Sew Department per dih b. Use the two production department factory overhead rates to determine the factory overhead per unit for each product. Small glove per unit Medium glove %24 per unit Large glove 24 per unit

Managerial Accounting

15th Edition

ISBN:9781337912020

Author:Carl Warren, Ph.d. Cma William B. Tayler

Publisher:Carl Warren, Ph.d. Cma William B. Tayler

Chapter4: Activity-based Costing

Section: Chapter Questions

Problem 5E: Handy Leather, Inc., produces three sizes of sports gloves: small, medium, and large. A glove...

Related questions

Question

Transcribed Image Text:Multiple Production Department Factory Overhead Rate

Method

Handy Leather, Inc., produces three sizes of sports gloves:

small, medium, and large. A glove pattern is first stenciled

onto leather in the Pattern Department. The stenciled

patterns are then sent to the Cut and Sew Department,

where the glove is cut and sewed together. Handy Leather

uses the multiple production department factory overhead

rate method of allocating factory overhead costs. Its factory

overhead costs were budgeted as follows:

Pattern Department overhead

$96,000

Cut and Sew Department overhead

160,000

Total

$256,000

The direct labor estimated for each production department

was as follows:

Pattern Department

2,000 direct labor hours

Cut and Sew Department

2,500

Total

4,500 direct labor hours

Direct labor hours are used to allocate the production

department overhead to the products. The direct labor

hours per unit for each product for each production

department were obtained from the engineering records as

follows:

Production Departments

Small Glove

Medium Glove

Large Glove

Pattern Department

0.04

0.05

0.06

Cut and Sew Department

0.07

0.09

0.11

Direct labor hours per unit

0.11

0.14

0.17

If required, round all per unit answers to the nearest

cent.

a. Determine the two production department factory

overhead rates.

Pattern Department

per dih

Cut and Sew Department

per dih

b. Use the two production department factory overhead

rates to determine the factory overhead per unit for each

product.

Small glove

per unit

Medium glove

%24

per unit

Large glove

24

per unit

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 4 steps with 4 images

Recommended textbooks for you

Managerial Accounting

Accounting

ISBN:

9781337912020

Author:

Carl Warren, Ph.d. Cma William B. Tayler

Publisher:

South-Western College Pub

Financial And Managerial Accounting

Accounting

ISBN:

9781337902663

Author:

WARREN, Carl S.

Publisher:

Cengage Learning,

Principles of Accounting Volume 2

Accounting

ISBN:

9781947172609

Author:

OpenStax

Publisher:

OpenStax College

Managerial Accounting

Accounting

ISBN:

9781337912020

Author:

Carl Warren, Ph.d. Cma William B. Tayler

Publisher:

South-Western College Pub

Financial And Managerial Accounting

Accounting

ISBN:

9781337902663

Author:

WARREN, Carl S.

Publisher:

Cengage Learning,

Principles of Accounting Volume 2

Accounting

ISBN:

9781947172609

Author:

OpenStax

Publisher:

OpenStax College

Cornerstones of Cost Management (Cornerstones Ser…

Accounting

ISBN:

9781305970663

Author:

Don R. Hansen, Maryanne M. Mowen

Publisher:

Cengage Learning

Managerial Accounting: The Cornerstone of Busines…

Accounting

ISBN:

9781337115773

Author:

Maryanne M. Mowen, Don R. Hansen, Dan L. Heitger

Publisher:

Cengage Learning