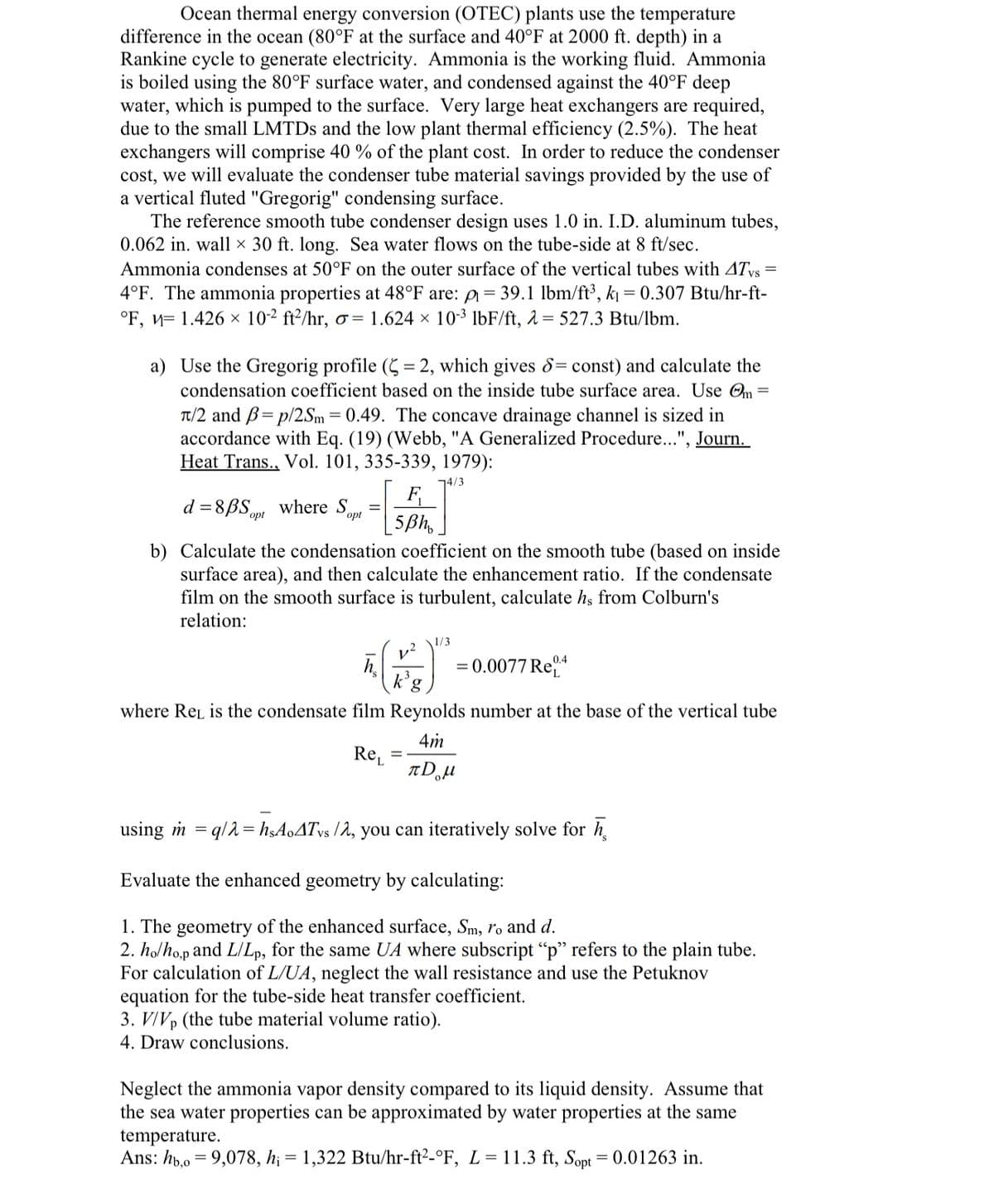

Ocean thermal energy conversion (OTEC) plants use the temperature difference in the ocean (80°F at the surface and 40°F at 2000 ft. depth) in a Rankine cycle to generate electricity. Ammonia is the working fluid. Ammonia is boiled using the 80°F surface water, and condensed against the 40°F deep water, which is pumped to the surface. Very large heat exchangers are required, due to the small LMTDs and the low plant thermal efficiency (2.5%). The heat exchangers will comprise 40 % of the plant cost. In order to reduce the condenser cost, we will evaluate the condenser tube material savings provided by the use of a vertical fluted "Gregorig" condensing surface. The reference smooth tube condenser design uses 1.0 in. I.D. aluminum tubes, 0.062 in. wall x 30 ft. long. Sea water flows on the tube-side at 8 ft/sec. Ammonia condenses at 50°F on the outer surface of the vertical tubes with 4Tvs = 4°F. The ammonia properties at 48°F are: p= 39.1 lbm/ft³, k₁= 0.307 Btu/hr-ft- °F, и 1.426 × 102 ft²/hr, o= 1.624 x 10-3 lbF/ft, λ = 527.3 Btu/lbm. a) Use the Gregorig profile (= 2, which gives 8= const) and calculate the condensation coefficient based on the inside tube surface area. Use Om = π/2 and B=p/2Sm = 0.49. The concave drainage channel is sized in accordance with Eq. (19) (Webb, "A Generalized Procedure...", Journ. Heat Trans., Vol. 101, 335-339, 1979): 74/3 d=8BS opt where Sopt = F₁ 5ph b) Calculate the condensation coefficient on the smooth tube (based on inside surface area), and then calculate the enhancement ratio. If the condensate film on the smooth surface is turbulent, calculate hs from Colburn's relation: ReL L² 1/3 where ReL is the condensate film Reynolds number at the base of the vertical tube 4m πDμ = = 0.0077 Re0.4 using m = q/2 = hsAoATvs /2, you can iteratively solve for h Evaluate the enhanced geometry by calculating: 1. The geometry of the enhanced surface, Sm, ro and d. 2. ho/hop and L/Lp, for the same UA where subscript "p" refers to the plain tube. For calculation of L/UA, neglect the wall resistance and use the Petuknov equation for the tube-side heat transfer coefficient. 3. V/V, (the tube material volume ratio).

Ocean thermal energy conversion (OTEC) plants use the temperature difference in the ocean (80°F at the surface and 40°F at 2000 ft. depth) in a Rankine cycle to generate electricity. Ammonia is the working fluid. Ammonia is boiled using the 80°F surface water, and condensed against the 40°F deep water, which is pumped to the surface. Very large heat exchangers are required, due to the small LMTDs and the low plant thermal efficiency (2.5%). The heat exchangers will comprise 40 % of the plant cost. In order to reduce the condenser cost, we will evaluate the condenser tube material savings provided by the use of a vertical fluted "Gregorig" condensing surface. The reference smooth tube condenser design uses 1.0 in. I.D. aluminum tubes, 0.062 in. wall x 30 ft. long. Sea water flows on the tube-side at 8 ft/sec. Ammonia condenses at 50°F on the outer surface of the vertical tubes with 4Tvs = 4°F. The ammonia properties at 48°F are: p= 39.1 lbm/ft³, k₁= 0.307 Btu/hr-ft- °F, и 1.426 × 102 ft²/hr, o= 1.624 x 10-3 lbF/ft, λ = 527.3 Btu/lbm. a) Use the Gregorig profile (= 2, which gives 8= const) and calculate the condensation coefficient based on the inside tube surface area. Use Om = π/2 and B=p/2Sm = 0.49. The concave drainage channel is sized in accordance with Eq. (19) (Webb, "A Generalized Procedure...", Journ. Heat Trans., Vol. 101, 335-339, 1979): 74/3 d=8BS opt where Sopt = F₁ 5ph b) Calculate the condensation coefficient on the smooth tube (based on inside surface area), and then calculate the enhancement ratio. If the condensate film on the smooth surface is turbulent, calculate hs from Colburn's relation: ReL L² 1/3 where ReL is the condensate film Reynolds number at the base of the vertical tube 4m πDμ = = 0.0077 Re0.4 using m = q/2 = hsAoATvs /2, you can iteratively solve for h Evaluate the enhanced geometry by calculating: 1. The geometry of the enhanced surface, Sm, ro and d. 2. ho/hop and L/Lp, for the same UA where subscript "p" refers to the plain tube. For calculation of L/UA, neglect the wall resistance and use the Petuknov equation for the tube-side heat transfer coefficient. 3. V/V, (the tube material volume ratio).

Refrigeration and Air Conditioning Technology (MindTap Course List)

8th Edition

ISBN:9781305578296

Author:John Tomczyk, Eugene Silberstein, Bill Whitman, Bill Johnson

Publisher:John Tomczyk, Eugene Silberstein, Bill Whitman, Bill Johnson

Chapter47: High-pressure, Low-pressure, And Absorption Chilled-water Systems

Section: Chapter Questions

Problem 13RQ: The subcooling temperature in a condenser can be measured by taking the difference between the A....

Related questions

Concept explainers

Heat Exchangers

Heat exchangers are the types of equipment that are primarily employed to transfer the thermal energy from one fluid to another, provided that one of the fluids should be at a higher thermal energy content than the other fluid.

Heat Exchanger

The heat exchanger is a combination of two words ''Heat'' and ''Exchanger''. It is a mechanical device that is used to exchange heat energy between two fluids.

Question

Transcribed Image Text:Ocean thermal energy conversion (OTEC) plants use the temperature

difference in the ocean (80°F at the surface and 40°F at 2000 ft. depth) in a

Rankine cycle to generate electricity. Ammonia is the working fluid. Ammonia

is boiled using the 80°F surface water, and condensed against the 40°F deep

water, which is pumped to the surface. Very large heat exchangers are required,

due to the small LMTDs and the low plant thermal efficiency (2.5%). The heat

exchangers will comprise 40 % of the plant cost. In order to reduce the condenser

cost, we will evaluate the condenser tube material savings provided by the use of

a vertical fluted "Gregorig" condensing surface.

The reference smooth tube condenser design uses 1.0 in. I.D. aluminum tubes,

0.062 in. wall x 30 ft. long. Sea water flows on the tube-side at 8 ft/sec.

Ammonia condenses at 50°F on the outer surface of the vertical tubes with 4Tvs =

4°F. The ammonia properties at 48°F are: p= 39.1 lbm/ft³, k₁= 0.307 Btu/hr-ft-

°F, и 1.426 × 10-2 ft²/hr, o 1.624 x 10-³ lbF/ft, 2 = 527.3 Btu/lbm.

a) Use the Gregorig profile (= 2, which gives S= const) and calculate the

condensation coefficient based on the inside tube surface area. Use Om =

π/2 and ß=p/2Sm = 0.49. The concave drainage channel is sized in

accordance with Eq. (19) (Webb, "A Generalized Procedure...", Journ.

Heat Trans., Vol. 101, 335-339, 1979):

14/3

d=8pS where S

opt

opt

F

5ph

b) Calculate the condensation coefficient on the smooth tube (based on inside

surface area), and then calculate the enhancement ratio. If the condensate

film on the smooth surface is turbulent, calculate hs from Colburn's

relation:

REL

V²

h

where ReL is the condensate film Reynolds number at the base of the vertical tube

4m

πDμ

1/3

=

= 0.0077 Re

using mq/2 = hsAoATvs /2, you can iteratively solve for h

Evaluate the enhanced geometry by calculating:

1. The geometry of the enhanced surface, Sm, ro and d.

2. ho/ho,p and L/Lp, for the same UA where subscript "p" refers to the plain tube.

For calculation of L/UA, neglect the wall resistance and use the Petuknov

equation for the tube-side heat transfer coefficient.

3. V/V, (the tube material volume ratio).

4. Draw conclusions.

Neglect the ammonia vapor density compared to its liquid density. Assume that

the sea water properties can be approximated by water properties at the same

temperature.

Ans: hb,o=9,078, h₁ = 1,322 Btu/hr-ft2-°F, L = 11.3 ft, Sopt = 0.01263 in.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 3 steps with 5 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Refrigeration and Air Conditioning Technology (Mi…

Mechanical Engineering

ISBN:

9781305578296

Author:

John Tomczyk, Eugene Silberstein, Bill Whitman, Bill Johnson

Publisher:

Cengage Learning

Refrigeration and Air Conditioning Technology (Mi…

Mechanical Engineering

ISBN:

9781305578296

Author:

John Tomczyk, Eugene Silberstein, Bill Whitman, Bill Johnson

Publisher:

Cengage Learning