P11-4A The elementary, irreversible, organic liquid-phase reaction A+B C is carried out adiabatically in a flow reactor. An equal molar feed in A and B enters at 27°C, and the volumetric flow rate is 2 dm³/s and CA0 = 0.1 kmol/m³. Additional information: H(273 K)=-20 kcal/mol, Hg (273 K) = -15 kcal/mol, H(273 K)=-41 kcal/mol = CP CP = 15 cal/mol-K Cpc = 30 cal/mol K k = 0.01 dm³ mol s at 300 K E = 10,000 cal/mol PFR (a) Plot and then analyze the conversion and temperature as a function of PFR volume up to where X=0.85. Describe the trends. (b) What is the maximum inlet temperature one could have so that the boiling point of the liquid (550 K) would not be exceeded even for complete conversion? (c) Plot the heat that must be removed along the reactor (Q vs. V) to maintain isothermal operation.

P11-4A The elementary, irreversible, organic liquid-phase reaction A+B C is carried out adiabatically in a flow reactor. An equal molar feed in A and B enters at 27°C, and the volumetric flow rate is 2 dm³/s and CA0 = 0.1 kmol/m³. Additional information: H(273 K)=-20 kcal/mol, Hg (273 K) = -15 kcal/mol, H(273 K)=-41 kcal/mol = CP CP = 15 cal/mol-K Cpc = 30 cal/mol K k = 0.01 dm³ mol s at 300 K E = 10,000 cal/mol PFR (a) Plot and then analyze the conversion and temperature as a function of PFR volume up to where X=0.85. Describe the trends. (b) What is the maximum inlet temperature one could have so that the boiling point of the liquid (550 K) would not be exceeded even for complete conversion? (c) Plot the heat that must be removed along the reactor (Q vs. V) to maintain isothermal operation.

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

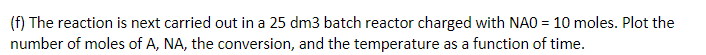

Transcribed Image Text:(f) The reaction is next carried out in a 25 dm3 batch reactor charged with NAO = 10 moles. Plot the

number of moles of A, NA, the conversion, and the temperature as a function of time.

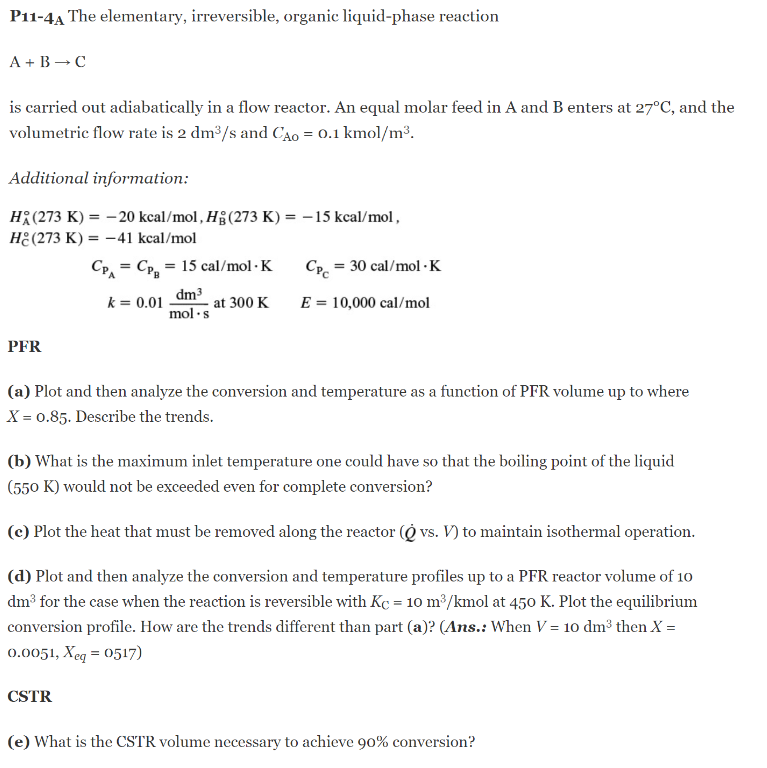

Transcribed Image Text:P11-4A The elementary, irreversible, organic liquid-phase reaction

A + B → C

is carried out adiabatically in a flow reactor. An equal molar feed in A and B enters at 27°C, and the

volumetric flow rate is 2 dm³/s and CÃO = 0.1 kmol/m³.

Additional information:

H(273 K) = -20 kcal/mol, Hg (273 K) = -15 kcal/mol,

He(273 K) = -41 kcal/mol

CPA = CP₂ = 15 cal/mol. K

k = 0.01

dm³

mol.s

at 300 K

PFR

Cpc = 30 cal/mol - K

E = 10,000 cal/mol

(a) Plot and then analyze the conversion and temperature as a function of PFR volume up to where

X = 0.85. Describe the trends.

(b) What is the maximum inlet temperature one could have so that the boiling point of the liquid

(550 K) would not be exceeded even for complete conversion?

(c) Plot the heat that must be removed along the reactor (O vs. V) to maintain isothermal operation.

(d) Plot and then analyze the conversion and temperature profiles up to a PFR reactor volume of 10

dm³ for the case when the reaction is reversible with Kc = 10 m³/kmol at 450 K. Plot the equilibrium

conversion profile. How are the trends different than part (a)? (Ans.: When V = 10 dm³ then X =

0.0051, Xeq = 0517)

CSTR

(e) What is the CSTR volume necessary to achieve 90% conversion?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps with 28 images

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The