Q1: In shape rolling, the final product is deformed into a countered cross-section like: (a) I-beam, L-beam, rails, H-beam and U-channel, (b) tubes, (c) screws, (d) gears (e) airfoil sections (f) bars and rods Q2: In two-high mill rolling (reversing type), the disadvantage is: (a) Compression force, (b) large roll diameter, (c) significant angular momentum, (d) large draft Q3: In four-high mill rolling, the roll force, torque and power are reduced due to: (a) Reduced contact length by lower radius of rolls, (b) large contact length, (c) low friction, (d) low draft Q4: In tandem rolling mill, the problem of synchronizing the roll speeds at each stand is a significant one because: (a) exit velocity of w.p. is increased after each rolling step, (b) increase the roll force, (c) exit velocity of w.p. is decreased, (d) increased draft

Q1: In shape rolling, the final product is deformed into a countered cross-section like: (a) I-beam, L-beam, rails, H-beam and U-channel, (b) tubes, (c) screws, (d) gears (e) airfoil sections (f) bars and rods Q2: In two-high mill rolling (reversing type), the disadvantage is: (a) Compression force, (b) large roll diameter, (c) significant angular momentum, (d) large draft Q3: In four-high mill rolling, the roll force, torque and power are reduced due to: (a) Reduced contact length by lower radius of rolls, (b) large contact length, (c) low friction, (d) low draft Q4: In tandem rolling mill, the problem of synchronizing the roll speeds at each stand is a significant one because: (a) exit velocity of w.p. is increased after each rolling step, (b) increase the roll force, (c) exit velocity of w.p. is decreased, (d) increased draft

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

Answer the following questions:

Transcribed Image Text:2:10

HW-3.pdf

Solutions of HW-3

1 of 3 owing questions:

75

Done

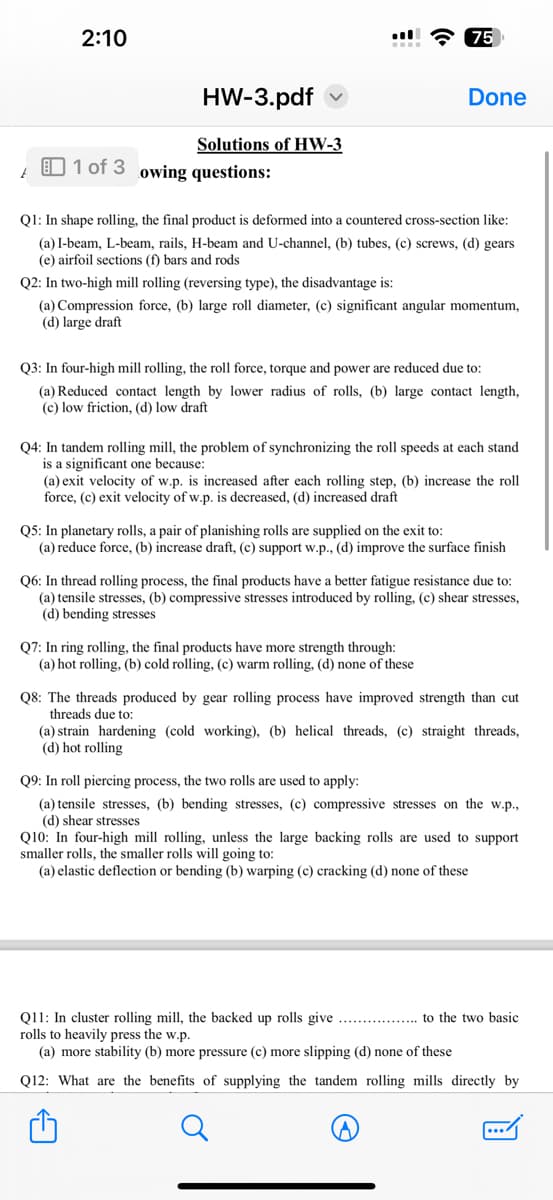

Q1: In shape rolling, the final product is deformed into a countered cross-section like:

(a) I-beam, L-beam, rails, H-beam and U-channel, (b) tubes, (c) screws, (d) gears

(e) airfoil sections (f) bars and rods

Q2: In two-high mill rolling (reversing type), the disadvantage is:

(a) Compression force, (b) large roll diameter, (c) significant angular momentum,

(d) large draft

Q3: In four-high mill rolling, the roll force, torque and power are reduced due to:

(a) Reduced contact length by lower radius of rolls, (b) large contact length,

(c) low friction, (d) low draft

Q4: In tandem rolling mill, the problem of synchronizing the roll speeds at each stand

is a significant one because:

(a) exit velocity of w.p. is increased after each rolling step, (b) increase the roll

force, (c) exit velocity of w.p. is decreased, (d) increased draft

Q5: In planetary rolls, a pair of planishing rolls are supplied on the exit to:

(a) reduce force, (b) increase draft, (c) support w.p., (d) improve the surface finish

Q7: In ring rolling, the final products have more strength through:

(a) hot rolling, (b) cold rolling, (c) warm rolling, (d) none of these

Q6: In thread rolling process, the final products have a better fatigue resistance due to:

(a) tensile stresses, (b) compressive stresses introduced by rolling, (c) shear stresses,

(d) bending stresses

Q8: The threads produced by gear rolling process have improved strength than cut

threads due to:

(a) strain hardening (cold working), (b) helical threads, (c) straight threads,

(d) hot rolling

Q9: In roll piercing process, the two rolls are used to apply:

(a) tensile stresses, (b) bending stresses, (c) compressive stresses on the w.p.,

(d) shear stresses

Q10: In four-high mill rolling, unless the large backing rolls are used to support

smaller rolls, the smaller rolls will going to:

(a) elastic deflection or bending (b) warping (c) cracking (d) none of these

Q11: In cluster rolling mill, the backed up rolls give

rolls to heavily press the w.p.

(a) more stability (b) more pressure (c) more slipping (d) none of these

Q12: What are the benefits of supplying the tandem rolling mills directly by

to the two basic

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY