QUESTION 14 A metal matrix composite consists of continuous silicon carbide fibres of radius 25 microns and volume fraction 0.35 embedded in a titanium matrix. The strength of the fibres is described by the Weibull parameters m=6, 00=2500 MPa and Lo=0.025 m. The titanium has a shear yield stress of Ty=165 MPa. Determine the ultimate tensile strength of the fibres, of", in MPa to zero decimal places.

QUESTION 14 A metal matrix composite consists of continuous silicon carbide fibres of radius 25 microns and volume fraction 0.35 embedded in a titanium matrix. The strength of the fibres is described by the Weibull parameters m=6, 00=2500 MPa and Lo=0.025 m. The titanium has a shear yield stress of Ty=165 MPa. Determine the ultimate tensile strength of the fibres, of", in MPa to zero decimal places.

Mechanics of Materials (MindTap Course List)

9th Edition

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Barry J. Goodno, James M. Gere

Chapter2: Axially Loaded Members

Section: Chapter Questions

Problem 2.5.1P: The rails of a railroad track are welded together at their ends (to form continuous rails and thus...

Related questions

Question

Q14

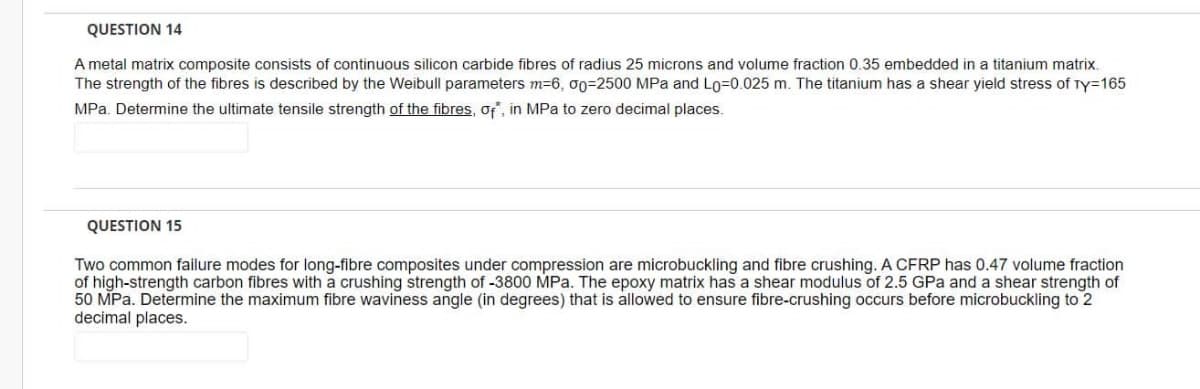

Transcribed Image Text:QUESTION 14

A metal matrix composite consists of continuous silicon carbide fibres of radius 25 microns and volume fraction 0.35 embedded in a titanium matrix.

The strength of the fibres is described by the Weibull parameters m=6, 00=2500 MPa and Lo=0.025 m. The titanium has a shear yield stress of Ty=165

MPa. Determine the ultimate tensile strength of the fibres, of", in MPa to zero decimal places.

QUESTION 15

Two common failure modes for long-fibre composites under compression are microbuckling and fibre crushing. A CFRP has 0.47 volume fraction

of high-strength carbon fibres with a crushing strength of -3800 MPa. The epoxy matrix has a shear modulus of 2.5 GPa and a shear strength of

50 MPa. Determine the maximum fibre waviness angle (in degrees) that is allowed to ensure fibre-crushing occurs before microbuckling to 2

decimal places.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning