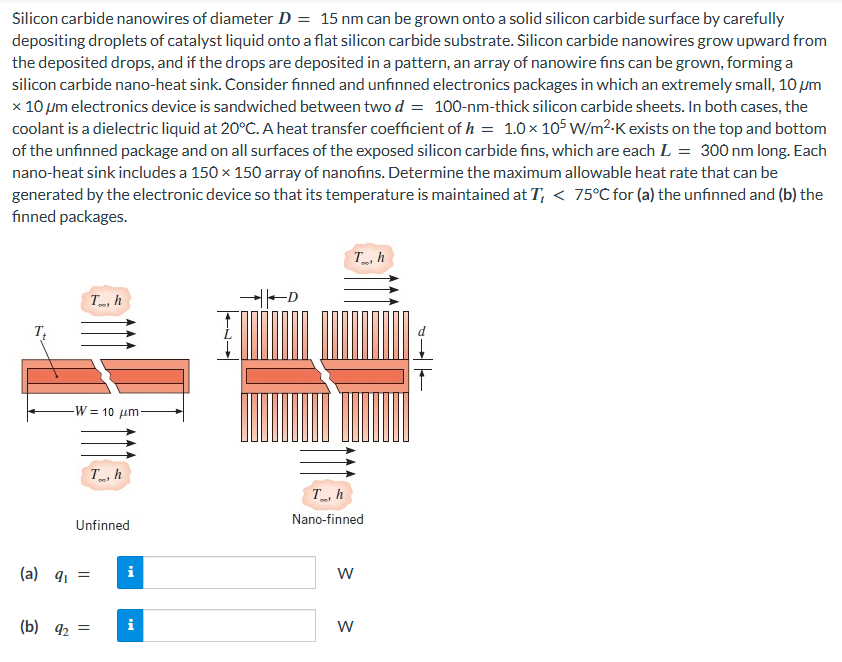

Silicon carbide nanowires of diameter D = 15 nm can be grown onto a solid silicon carbide surface by carefully depositing droplets of catalyst liquid onto a flat silicon carbide substrate. Silicon carbide nanowires grow upward from the deposited drops, and if the drops are deposited in a pattern, an array of nanowire fins can be grown, forming a silicon carbide nano-heat sink. Consider finned and unfinned electronics packages in which an extremely small, 10 μm x 10 μm electronics device is sandwiched between two d = 100-nm-thick silicon carbide sheets. In both cases, the coolant is a dielectric liquid at 20°C. A heat transfer coefficient of h = 1.0 × 105 W/m²-K exists on the top and bottom of the unfinned package and on all surfaces of the exposed silicon carbide fins, which are each L = 300 nm long. Each nano-heat sink includes a 150 × 150 array of nanofins. Determine the maximum allowable heat rate that can be generated by the electronic device so that its temperature is maintained at T, < 75°C for (a) the unfinned and (b) the finned packages.

Silicon carbide nanowires of diameter D = 15 nm can be grown onto a solid silicon carbide surface by carefully depositing droplets of catalyst liquid onto a flat silicon carbide substrate. Silicon carbide nanowires grow upward from the deposited drops, and if the drops are deposited in a pattern, an array of nanowire fins can be grown, forming a silicon carbide nano-heat sink. Consider finned and unfinned electronics packages in which an extremely small, 10 μm x 10 μm electronics device is sandwiched between two d = 100-nm-thick silicon carbide sheets. In both cases, the coolant is a dielectric liquid at 20°C. A heat transfer coefficient of h = 1.0 × 105 W/m²-K exists on the top and bottom of the unfinned package and on all surfaces of the exposed silicon carbide fins, which are each L = 300 nm long. Each nano-heat sink includes a 150 × 150 array of nanofins. Determine the maximum allowable heat rate that can be generated by the electronic device so that its temperature is maintained at T, < 75°C for (a) the unfinned and (b) the finned packages.

Principles of Heat Transfer (Activate Learning with these NEW titles from Engineering!)

8th Edition

ISBN:9781305387102

Author:Kreith, Frank; Manglik, Raj M.

Publisher:Kreith, Frank; Manglik, Raj M.

Chapter4: Numerical Analysis Of Heat Conduction

Section: Chapter Questions

Problem 4.54P

Related questions

Question

silicon carbide (T ≈ 300 K): k = 490 W/m⋅K .

Transcribed Image Text:Silicon carbide nanowires of diameter D = 15 nm can be grown onto a solid silicon carbide surface by carefully

depositing droplets of catalyst liquid onto a flat silicon carbide substrate. Silicon carbide nanowires grow upward from

the deposited drops, and if the drops are deposited in a pattern, an array of nanowire fins can be grown, forming a

silicon carbide nano-heat sink. Consider finned and unfinned electronics packages in which an extremely small, 10 μm

x 10 μm electronics device is sandwiched between two d = 100-nm-thick silicon carbide sheets. In both cases, the

coolant is a dielectric liquid at 20°C. A heat transfer coefficient of h = 1.0 × 105 W/m²-K exists on the top and bottom

of the unfinned package and on all surfaces of the exposed silicon carbide fins, which are each L = 300 nm long. Each

nano-heat sink includes a 150 × 150 array of nanofins. Determine the maximum allowable heat rate that can be

generated by the electronic device so that its temperature is maintained at T, < 75°C for (a) the unfinned and (b) the

finned packages.

To, h

-W= 10 μm-

Th

Unfinned

(a) q₁ =

(b) 9₂ =

i

i

Th

Th

Nano-finned

W

W

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Principles of Heat Transfer (Activate Learning wi…

Mechanical Engineering

ISBN:

9781305387102

Author:

Kreith, Frank; Manglik, Raj M.

Publisher:

Cengage Learning

Principles of Heat Transfer (Activate Learning wi…

Mechanical Engineering

ISBN:

9781305387102

Author:

Kreith, Frank; Manglik, Raj M.

Publisher:

Cengage Learning