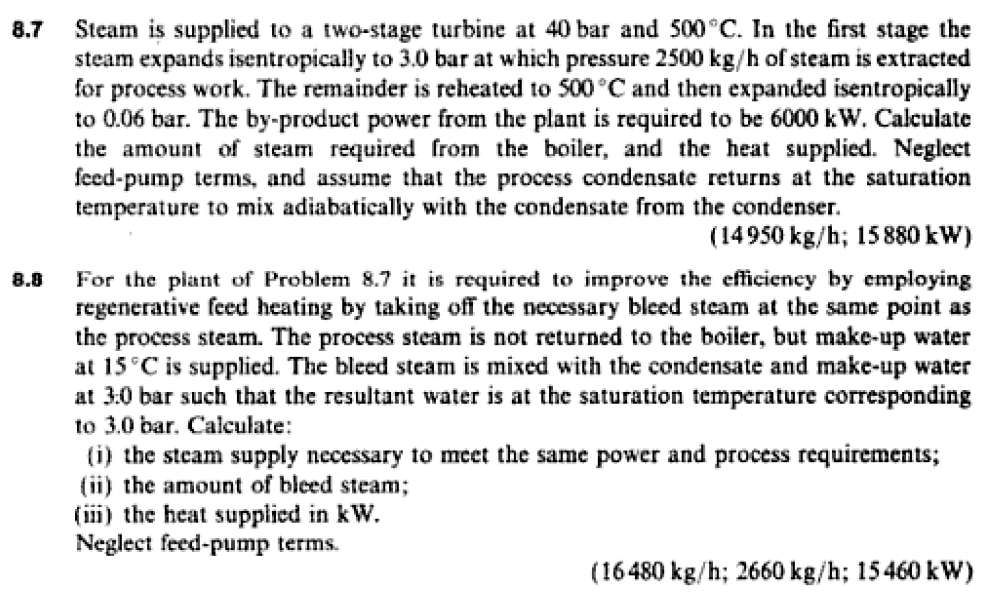

Steam is supplied to a two-stage turbine at 40 bar and 500°C. In the first stage the steam expands isentropically to 3.0 bar at which pressure 2500 kg/h of steam is extracted for process work. The remainder is reheated to 500 °C and then expanded isentropically to 0.06 bar. The by-product power from the plant is required to be 6000 kW. Calculate the amount of steam required from the boiler, and the heat supplied. Neglect feed-pump terms, and assume that the process condensate returns at the saturation temperature to mix adiabatically with the condensate from the condenser.

Steam is supplied to a two-stage turbine at 40 bar and 500°C. In the first stage the steam expands isentropically to 3.0 bar at which pressure 2500 kg/h of steam is extracted for process work. The remainder is reheated to 500 °C and then expanded isentropically to 0.06 bar. The by-product power from the plant is required to be 6000 kW. Calculate the amount of steam required from the boiler, and the heat supplied. Neglect feed-pump terms, and assume that the process condensate returns at the saturation temperature to mix adiabatically with the condensate from the condenser.

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

solve both of the questions in the picture

Transcribed Image Text:Steam is supplied to a two-stage turbine at 40 bar and 500°C. In the first stage the

steam expands isentropically to 3.0 bar at which pressure 2500 kg/h of steam is extracted

for process work. The remainder is reheated to 500°C and then expanded isentropically

to 0.06 bar. The by-product power from the plant is required to be 6000 kW. Calculate

the amount of steam required from the boiler, and the heat supplied. Neglect

feed-pump terms, and assume that the process condensate returns at the saturation

temperature to mix adiabatically with the condensate from the condenser.

8.7

(14950 kg/h; 15880 kW)

For the piant of Problem 8.7 it is required to improve the efficiency by employing

regenerative feed heating by taking off the necessary bleed steam at the same point as

the process steam. The process steam is not returned to the boiler, but make-up water

at 15°C is supplied. The bleed steam is mixed with the condensate and make-up water

at 3:0 bar such that the resultant water is at the saturation temperature corresponding

to 3.0 bar. Calculate:

(i) the steam supply necessary to meet the same power and process requirements;

(ii) the amount of bleed steam;

(iii) the heat supplied in kW.

Neglect feed-pump terms.

8.8

(16480 kg/h; 2660 kg/h; 15460 kW)

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 3 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY