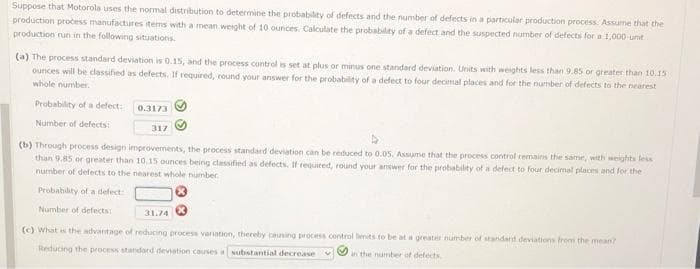

Suppose that Motorola uses the normal distribution to determine the probability of defects and the number of defects in a particular production process. Assume that the production process manufactures items with a mean weight of 10 ounces. Calculate the probability of a defect and the suspected number of defects for a 1,000-umit production run in the following situations. (a) The process standard deviation is 0.15, and the process control is set at plus or minus one standard deviation. Units with weights less than 9.85 or greater than 10.15 ounces will be dassified as defects. If required, round your answer for the probability of a defect to four decimal places and for the number of defects to the nearest whole number. Probability of a defect: 0.3173 Number of defects: 317 (b) Through process design improvements, the process standard deviation can be reduced to 0.05. Assume that the process control remains the same, with weights less than 9.85 or greater than 10,15 ounces being classified as defects. If required, round your answer for the probability of a defect to four decimal places and for the number of defects to the nearest whole number Probability of a defect Number of defects: 31.74 () What is the advantage of reducing process varation, thereby causing process control lenits to be at a greater number of standarnd deviations from the mean? Reducing the process standard deviation couses a substantial decrease in the number of defects

Suppose that Motorola uses the normal distribution to determine the probability of defects and the number of defects in a particular production process. Assume that the production process manufactures items with a mean weight of 10 ounces. Calculate the probability of a defect and the suspected number of defects for a 1,000-umit production run in the following situations. (a) The process standard deviation is 0.15, and the process control is set at plus or minus one standard deviation. Units with weights less than 9.85 or greater than 10.15 ounces will be dassified as defects. If required, round your answer for the probability of a defect to four decimal places and for the number of defects to the nearest whole number. Probability of a defect: 0.3173 Number of defects: 317 (b) Through process design improvements, the process standard deviation can be reduced to 0.05. Assume that the process control remains the same, with weights less than 9.85 or greater than 10,15 ounces being classified as defects. If required, round your answer for the probability of a defect to four decimal places and for the number of defects to the nearest whole number Probability of a defect Number of defects: 31.74 () What is the advantage of reducing process varation, thereby causing process control lenits to be at a greater number of standarnd deviations from the mean? Reducing the process standard deviation couses a substantial decrease in the number of defects

Operations Research : Applications and Algorithms

4th Edition

ISBN:9780534380588

Author:Wayne L. Winston

Publisher:Wayne L. Winston

Chapter16: Probabilistic Inventory Models

Section16.6: The Eoq With Uncertain Demand: The (r, Q) And (s, S) Models

Problem 1P

Related questions

Question

Transcribed Image Text:Suppose that Motorola uses the normal distribution to determine the probability of defects and the number of defects in a particular production process. Assume that the

production process manufactures items with a mean weight of 10 ounces. Calculate the probability of a defect and the suspected number of defects for a 1,000-umit

production run in the following situations.

(a) The process standard deviation is 0.15, and the process control is set at plus or minus one standard deviation. Units with weights less than 9.85 or greater than 10.15

ounces will be classified as defects. If required, round your answer for the probability of a defect to four decimal places and for the number of defects to the nearest

whole number.

Probability

of a defect:

0.3173

Number of defects:

317

(b) Through process design improvements, the process standard deviation can be reduced to 0.05. Assume that the process control remains the same, with weights less

than 9.85 or greater than 10,15 ounces being classified as defects. If required, round your answer for the probability of a defect to four decimal places and for the

number of defects to the nearest whole number

Probability of a defect

Number of defects

31.74

() What is the advantage of reducing process vanation, thereby causing process control lenits to be at a greater number of standarnd deviations from the mean?

Reducing the process standard deviation .couses a substantial decrease

in the number of defects

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 4 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, computer-science and related others by exploring similar questions and additional content below.Recommended textbooks for you

Operations Research : Applications and Algorithms

Computer Science

ISBN:

9780534380588

Author:

Wayne L. Winston

Publisher:

Brooks Cole

Operations Research : Applications and Algorithms

Computer Science

ISBN:

9780534380588

Author:

Wayne L. Winston

Publisher:

Brooks Cole