The same Client has undertaken kinetic studies corresponding to the hydrolysis of aqueous acetic anhydride (to yield acetic acid) at 40 °C. They have found that this is a first-order, irreversible reaction, with a rate constant of 0.38 min ¹. The Client is interested in scaling-up their acetic anhydride process, and have proposed the following two alternatives (written in red). 2 Notes from Client • A CSTR thermostatted at 40 °C, of 1.8 L volume, with an input stream of aqueous acetic anhydride at a concentration of 0.187 M. • • • o This has actually been tested in our labs - for an entry volume flow rate of 0.5 L min-¹, we observed that 58.3% of the acetic anhydride was converted. A plug-flow reactor thermostatted at 40 °C, of the same volume as the CSTR, with the same volume flow rate. Notes from Team Leader How do the Client's experimental results with the CSTR compare with their batch reactor findings? In terms of productivity, which of the two options do you recommend? If the two alternatives were to have the same conversion, how would the flow rates differ? Does this change your recommendation?

The same Client has undertaken kinetic studies corresponding to the hydrolysis of aqueous acetic anhydride (to yield acetic acid) at 40 °C. They have found that this is a first-order, irreversible reaction, with a rate constant of 0.38 min ¹. The Client is interested in scaling-up their acetic anhydride process, and have proposed the following two alternatives (written in red). 2 Notes from Client • A CSTR thermostatted at 40 °C, of 1.8 L volume, with an input stream of aqueous acetic anhydride at a concentration of 0.187 M. • • • o This has actually been tested in our labs - for an entry volume flow rate of 0.5 L min-¹, we observed that 58.3% of the acetic anhydride was converted. A plug-flow reactor thermostatted at 40 °C, of the same volume as the CSTR, with the same volume flow rate. Notes from Team Leader How do the Client's experimental results with the CSTR compare with their batch reactor findings? In terms of productivity, which of the two options do you recommend? If the two alternatives were to have the same conversion, how would the flow rates differ? Does this change your recommendation?

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

see image

Transcribed Image Text:processing?

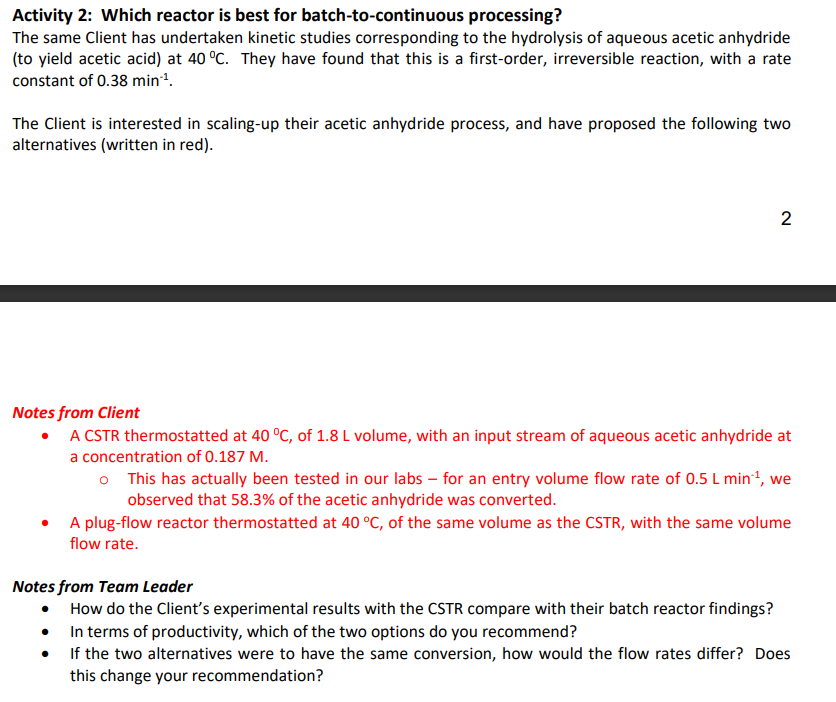

Activity 2: Which reactor is best for batch-to-continuous

The same Client has undertaken kinetic studies corresponding to the hydrolysis of aqueous acetic anhydride

(to yield acetic acid) at 40 °C. They have found that this is a first-order, irreversible reaction, with a rate

constant of 0.38 min ¹.

The Client is interested in scaling-up their acetic anhydride process, and have proposed the following two

alternatives (written in red).

2

Notes from Client

• A CSTR thermostatted at 40 °C, of 1.8 L volume, with an input stream of aqueous acetic anhydride at

a concentration of 0.187 M.

o This has actually been tested in our labs - for an entry volume flow rate of 0.5 L min-¹, we

observed that 58.3% of the acetic anhydride was converted.

A plug-flow reactor thermostatted at 40 °C, of the same volume as the CSTR, with the same volume

flow rate.

Notes from Team Leader

• How do the Client's experimental results with the CSTR compare with their batch reactor findings?

In terms of productivity, which of the two options do you recommend?

•

If the two alternatives were to have the same conversion, how would the flow rates differ? Does

this change your recommendation?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 4 steps

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The