This exercise contains only parts a and b. a) For the given data, the x = hours (round your response to three decimal places). For the given data, mean range = hours (round your response to two decimal places). With z=3, the control limits for the mean chart are:

This exercise contains only parts a and b. a) For the given data, the x = hours (round your response to three decimal places). For the given data, mean range = hours (round your response to two decimal places). With z=3, the control limits for the mean chart are:

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter2: Introduction To Spreadsheet Modeling

Section: Chapter Questions

Problem 20P: Julie James is opening a lemonade stand. She believes the fixed cost per week of running the stand...

Related questions

Question

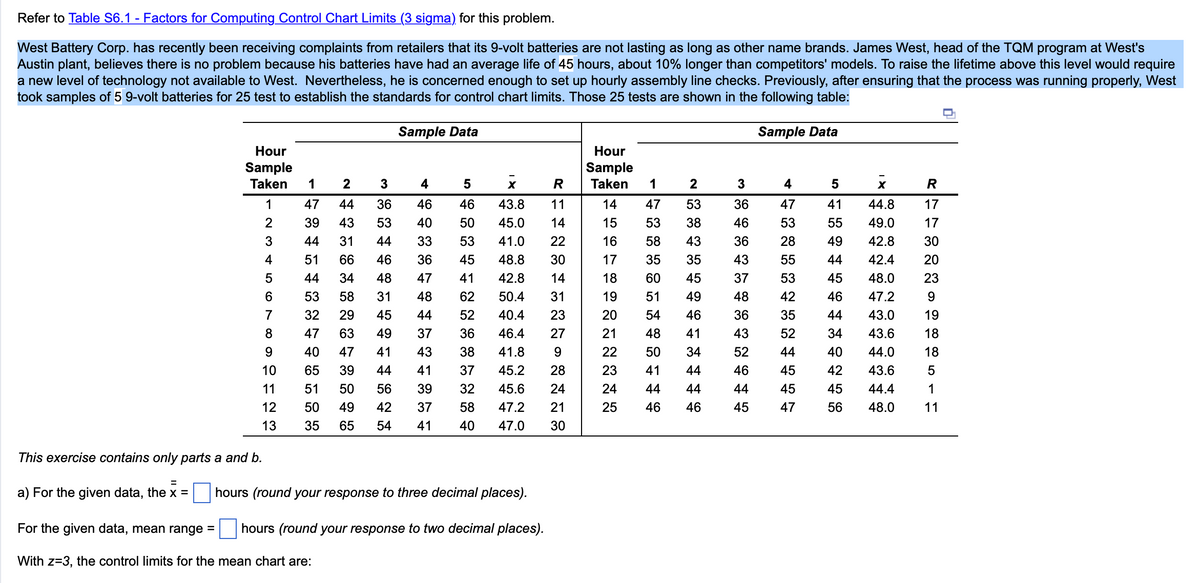

Transcribed Image Text:Refer to Table S6.1 - Factors for Computing Control Chart Limits (3 sigma) for this problem.

West Battery Corp. has recently been receiving complaints from retailers that its 9-volt batteries are not lasting as long as other name brands. James West, head of the TQM program at West's

Austin plant, believes there is no problem because his batteries have had an average life of 45 hours, about 10% longer than competitors' models. To raise the lifetime above this level would require

a new level of technology not available to West. Nevertheless, he is concerned enough to set up hourly assembly line checks. Previously, after ensuring that the process was running properly, West

took samples of 5 9-volt batteries for 25 test to establish the standards for control chart limits. Those 25 tests are shown in the following table:

Sample Data

Sample Data

Hour

Sample

Taken 1 2

This exercise contains only parts a and b.

=

a) For the given data, the x =

1

2

3

4

5

6

7

8

9

10

11

12

13

3

4

5

X

R

47 44

36

46

46 43.8

11

39 43 53

40

50

14

45.0

41.0

44 31

44

33

53

51

66

46

36

45

44 34 48

47

41

53 58

31

48

62

32

29

45 44

52

47

63

49

22

48.8 30

42.8 14

50.4 31

40.4 23

46.4

41.8

45.2

45.6

58 47.2

41 40 47.0

37

36

27

40 47

41

43 38

9

28

65

39 44

41 37

51 50 56

39

32

24

50 49 42

37

21

35

65 54

30

hours (round your response to three decimal places).

hours (round your response to two decimal places).

For the given data, mean range =

With z=3, the control limits for the mean chart are:

Hour

Sample

Taken 1

2

47

53

53

38

16

58 43

17

35

35

18 60

45

19 51 49

20

54

46

41

14 15

222222

21

23

24

25

86444

50 34

44

44

46

41

3

36

46

36

43

37

48

36

43

52

46

44

45

4

47

53

28

55

53

42

35

52

44

45

45

47

5

X

R

41

44.8

17

55

17

49.0

42.8

49

30

44 42.4

20

45 48.0 23

46

44

47.2

43.0

43.6

9

19

18

34

40 44.0

18

42

43.6

45

44.4

5

1

11

56

48.0

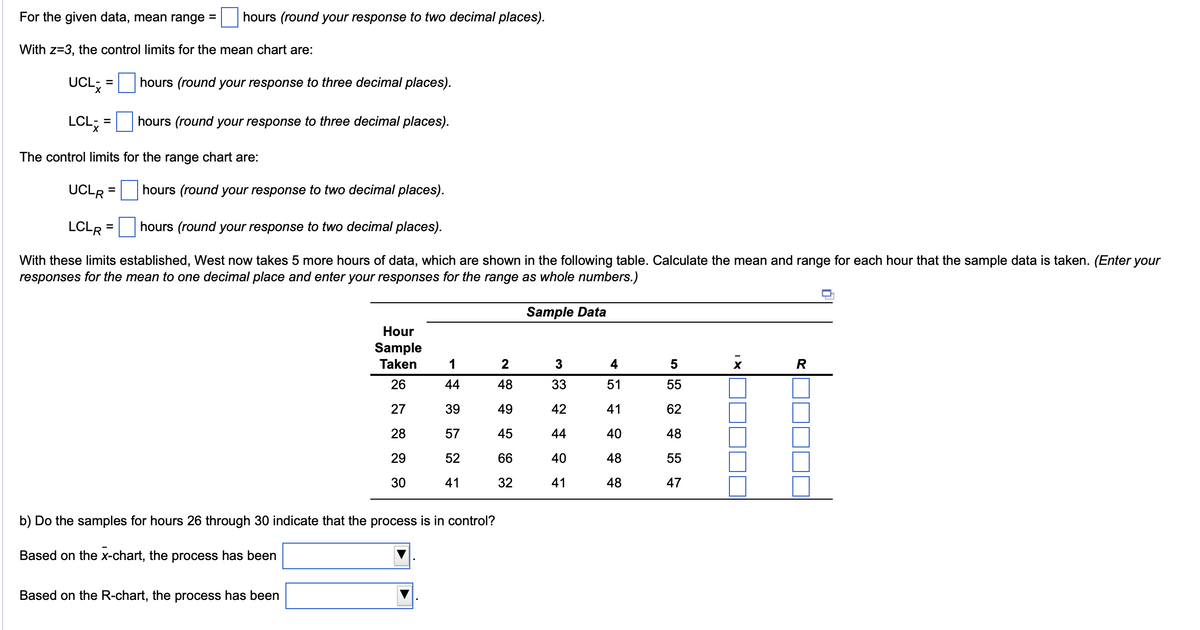

Transcribed Image Text:For the given data, mean range =

With z=3, the control limits for the mean chart are:

UCLX

UCLR

LCL X

The control limits for the range chart are:

LCLR

hours (round your response to two decimal places).

= hours (round your response to three decimal places).

=

hours (round your response to three decimal places).

hours (round your response to two decimal places).

= hours (round your response to two decimal places).

With these limits established, West now takes 5 more hours of data, which are shown in the following table. Calculate the mean and range for each hour that the sample data is taken. (Enter your

responses for the mean to one decimal place and enter your responses for the range as whole numbers.)

Sample Data

Hour

Sample

Taken

26

27

28

29

30

Based on the R-chart, the process has been

1

44

39

57

52

41

b) Do the samples for hours 26 through 30 indicate that the process is in control?

Based on the x-chart, the process has been

2

48

49

45

66

32

± 8 ☆ ww

33

42

44

40

41

4

51

41

40

48

48

5

55

62

48

55

47

X

R

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps with 2 images

Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning

Production and Operations Analysis, Seventh Editi…

Operations Management

ISBN:

9781478623069

Author:

Steven Nahmias, Tava Lennon Olsen

Publisher:

Waveland Press, Inc.