What if Fisher Company had 10 additional machine hours (cutting) with all other resources held constant? What is the new optimal mix? What is the associated total contribution margin? Round the units of A and B to two decimal places, and round intermediate calculations and your final answer to the nearest dollar.

What if Fisher Company had 10 additional machine hours (cutting) with all other resources held constant? What is the new optimal mix? What is the associated total contribution margin? Round the units of A and B to two decimal places, and round intermediate calculations and your final answer to the nearest dollar.

Operations Research : Applications and Algorithms

4th Edition

ISBN:9780534380588

Author:Wayne L. Winston

Publisher:Wayne L. Winston

Chapter4: The Simplex Algorithm And Goal Programming

Section4.16: Multiattribute Decision Making In The Absence Of Uncertainty: Goal Programming

Problem 3P

Related questions

Question

What if Fisher Company had 10 additional machine hours (cutting) with all other resources held constant? What is the new optimal mix?

What is the associated total contribution margin? Round the units of A and B to two decimal places, and round intermediate calculations and your final answer to the nearest dollar.

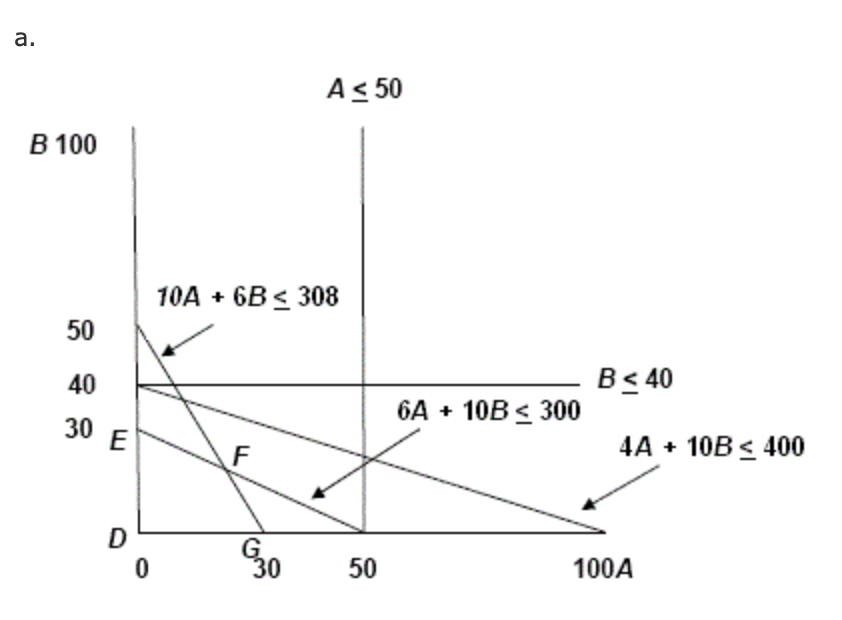

Transcribed Image Text:а.

A< 50

В 100

10A + 6B < 308

50

40

B< 40

6A + 10B < 300

30

E

4A + 10B < 400

F

50

100A

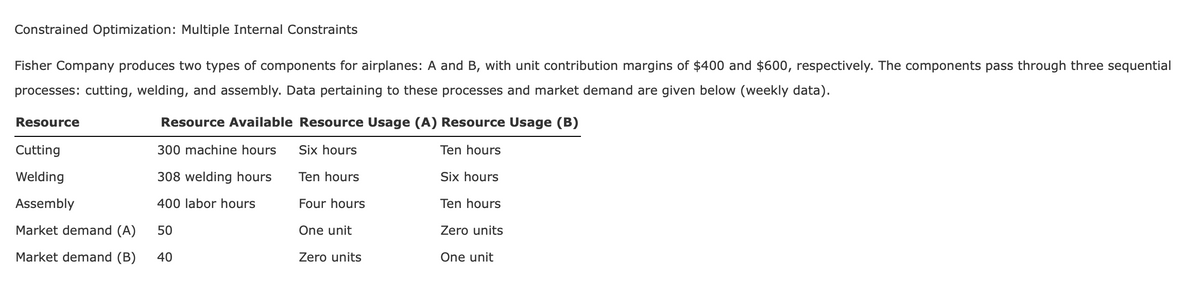

Transcribed Image Text:Constrained Optimization: Multiple Internal Constraints

Fisher Company produces two types of components for airplanes: A and B, with unit contribution margins of $400 and $600, respectively. The components pass through three sequential

processes: cutting, welding, and assembly. Data pertaining to these processes and market demand are given below (weekly data).

Resource

Resource Available Resource Usage (A) Resource Usage (B)

Cutting

300 machine hours

Six hours

Ten hours

Welding

308 welding hours

Ten hours

Six hours

Assembly

400 labor hours

Four hours

Ten hours

Market demand (A)

50

One unit

Zero units

Market demand (B)

40

Zero units

One unit

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, computer-science and related others by exploring similar questions and additional content below.Recommended textbooks for you

Operations Research : Applications and Algorithms

Computer Science

ISBN:

9780534380588

Author:

Wayne L. Winston

Publisher:

Brooks Cole

Operations Research : Applications and Algorithms

Computer Science

ISBN:

9780534380588

Author:

Wayne L. Winston

Publisher:

Brooks Cole