d Angela Pasaic spent e Southwest. While at the ey made use of their co Opened their plant in Ne Ouse to make a clay deriv

d Angela Pasaic spent e Southwest. While at the ey made use of their co Opened their plant in Ne Ouse to make a clay deriv

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter2: Introduction To Spreadsheet Modeling

Section: Chapter Questions

Problem 20P: Julie James is opening a lemonade stand. She believes the fixed cost per week of running the stand...

Related questions

Question

Create a step-by-step excel, using the solver engine to generate the decision variable

solution. Generate an ANSWER REPORT and a SENSITIVITY REPORT. I WILL UPVOTE. THANK YOU

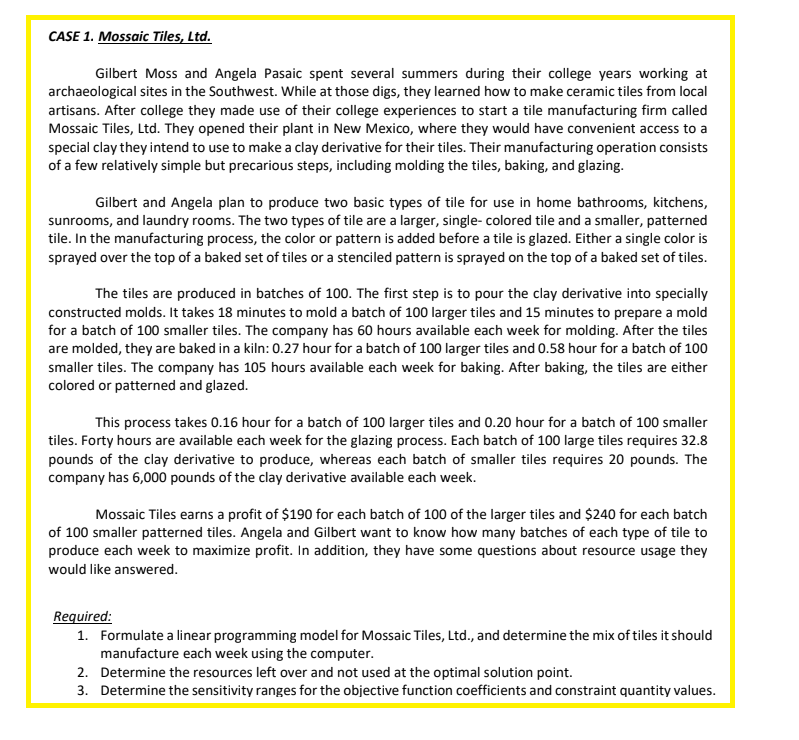

Transcribed Image Text:CASE 1. Mossaic Tiles, Ltd.

Gilbert Moss and Angela Pasaic spent several summers during their college years working at

archaeological sites in the Southwest. While at those digs, they learned how to make ceramic tiles from local

artisans. After college they made use of their college experiences to start a tile manufacturing firm called

Mossaic Tiles, Ltd. They opened their plant in New Mexico, where they would have convenient access to a

special clay they intend to use to make a clay derivative for their tiles. Their manufacturing operation consists

of a few relatively simple but precarious steps, including molding the tiles, baking, and glazing.

Gilbert and Angela plan to produce two basic types of tile for use in home bathrooms, kitchens,

sunrooms, and laundry rooms. The two types of tile are a larger, single-colored tile and a smaller, patterned

tile. In the manufacturing process, the color or pattern is added before a tile is glazed. Either a single color is

sprayed over the top of a baked set of tiles or a stenciled pattern is sprayed on the top of a baked set of tiles.

The tiles are produced in batches of 100. The first step is to pour the clay derivative into specially

constructed molds. It takes 18 minutes to mold a batch of 100 larger tiles and 15 minutes to prepare a mold

for a batch of 100 smaller tiles. The company has 60 hours available each week for molding. After the tiles

are molded, they are baked in a kiln: 0.27 hour for a batch of 100 larger tiles and 0.58 hour for a batch of 100

smaller tiles. The company has 105 hours available each week for baking. After baking, the tiles are either

colored or patterned and glazed.

This process takes 0.16 hour for a batch of 100 larger tiles and 0.20 hour for a batch of 100 smaller

tiles. Forty hours are available each week for the glazing process. Each batch of 100 large tiles requires 32.8

pounds of the clay derivative to produce, whereas each batch of smaller tiles requires 20 pounds. The

company has 6,000 pounds of the clay derivative available each week.

Mossaic Tiles earns a profit of $190 for each batch of 100 of the larger tiles and $240 for each batch

of 100 smaller patterned tiles. Angela and Gilbert want to know how many batches of each type of tile to

produce each week to maximize profit. In addition, they have some questions about resource usage they

would like answered.

Required:

1. Formulate a linear programming model for Mossaic Tiles, Ltd., and determine the mix of tiles it should

manufacture each week using the computer.

2. Determine the resources left over and not used at the optimal solution point.

3. Determine the sensitivity ranges for the objective function coefficients and constraint quantity values.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 4 steps with 8 images

Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning

Production and Operations Analysis, Seventh Editi…

Operations Management

ISBN:

9781478623069

Author:

Steven Nahmias, Tava Lennon Olsen

Publisher:

Waveland Press, Inc.