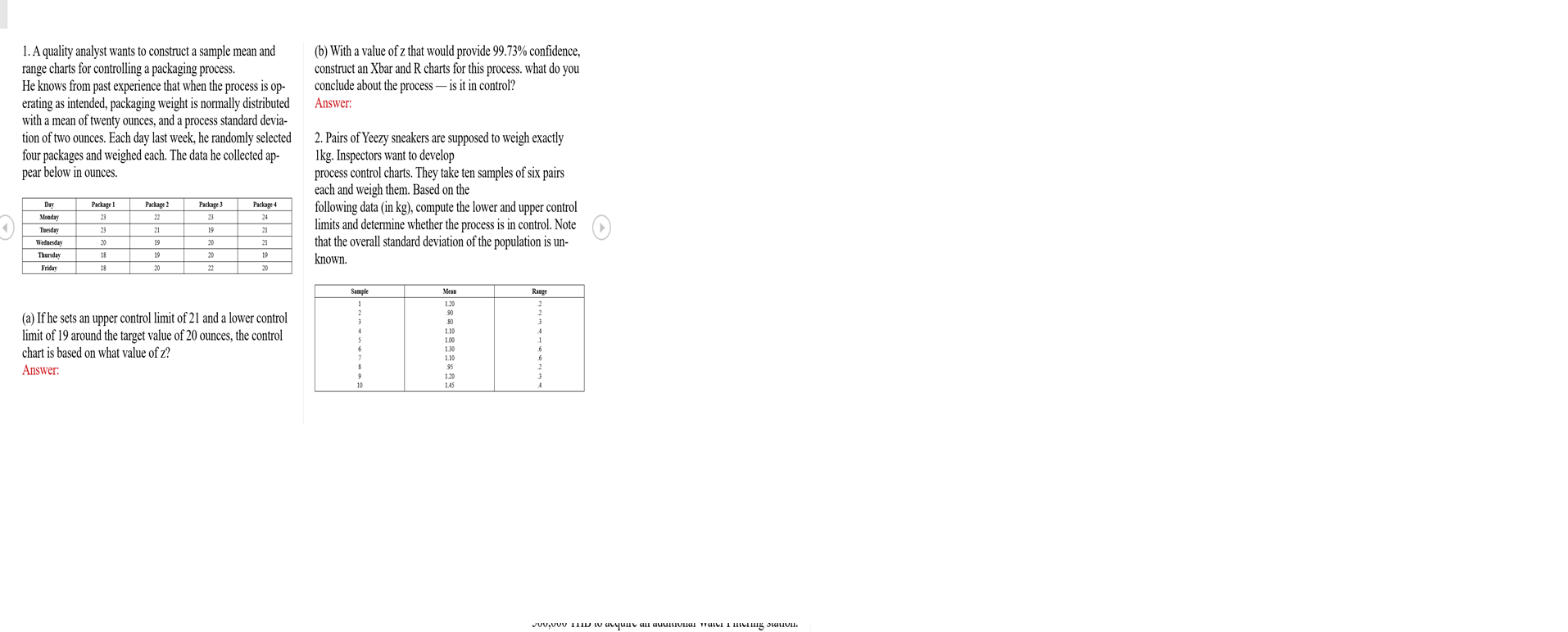

1. A quality analyst wants to construct a sample mean and range charts for controlling a packaging process. He knows from past experience that when the process is op- erating as intended, packaging weight is normally distributed with a mean of twenty ounces, and a process standard devia- tion of two ounces. Each day last week, he randomly selected 2. Pairs of Yeezy sneakers are supposed to weigh exactly four packages and weighed each. The data he collected ap- pear below in ounces. (b) With a value of z that would provide 99.73% confidence, construct an Xbar and R charts for this process. what do you conclude about the process – is it in control? Answer: Ikg. Inspectors want to develop process control charts. They take ten samples of six pairs each and weigh them. Based on the following data (in kg), compute the lower and upper control limits and determine whether the process is in control. Note that the overall standard deviation of the population is un- known. Day Package 1 Package 2 Package 3 Package 4 Moaday 23 22 23 24 Tuesday 23 21 19 21 Wedaesday 20 19 20 21 Thursday 18 19 20 19 Friday 18 20 22 20 Sample Mean Range 120 (a) If he sets an upper control limit of 21 and a lower control limit of 19 around the target value of 20 ounces, the control chart is based on what value of z? 90 80 1.10 1.00 130 10 Answer: 95 1.20 10 1.45

1. A quality analyst wants to construct a sample mean and range charts for controlling a packaging process. He knows from past experience that when the process is op- erating as intended, packaging weight is normally distributed with a mean of twenty ounces, and a process standard devia- tion of two ounces. Each day last week, he randomly selected 2. Pairs of Yeezy sneakers are supposed to weigh exactly four packages and weighed each. The data he collected ap- pear below in ounces. (b) With a value of z that would provide 99.73% confidence, construct an Xbar and R charts for this process. what do you conclude about the process – is it in control? Answer: Ikg. Inspectors want to develop process control charts. They take ten samples of six pairs each and weigh them. Based on the following data (in kg), compute the lower and upper control limits and determine whether the process is in control. Note that the overall standard deviation of the population is un- known. Day Package 1 Package 2 Package 3 Package 4 Moaday 23 22 23 24 Tuesday 23 21 19 21 Wedaesday 20 19 20 21 Thursday 18 19 20 19 Friday 18 20 22 20 Sample Mean Range 120 (a) If he sets an upper control limit of 21 and a lower control limit of 19 around the target value of 20 ounces, the control chart is based on what value of z? 90 80 1.10 1.00 130 10 Answer: 95 1.20 10 1.45

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter2: Introduction To Spreadsheet Modeling

Section: Chapter Questions

Problem 20P: Julie James is opening a lemonade stand. She believes the fixed cost per week of running the stand...

Related questions

Question

please help answer part a and b for question 1. Please answer question 2 as well.

Transcribed Image Text:1. A quality analyst wants to construct a sample mean and

range charts for controlling a packaging process.

He knows from past experience that when the process is op-

erating as intended, packaging weight is normally distributed

with a mean of twenty ounces, and a process standard devia-

tion of two ounces. Each day last week, he randomly selected 2. Pairs of Yeezy sneakers are supposed to weigh exactly

four packages and weighed each. The data he collected ap-

pear below in ounces.

(b) With a value of z that would provide 99.73% confidence,

construct an Xbar and R charts for this process. what do you

conclude about the process – is it in control?

Answer:

Ikg. Inspectors want to develop

process control charts. They take ten samples of six pairs

each and weigh them. Based on the

following data (in kg), compute the lower and upper control

limits and determine whether the process is in control. Note

that the overall standard deviation of the population is un-

known.

Day

Package 1

Package 2

Package 3

Package 4

Moaday

23

22

23

24

Tuesday

23

21

19

21

Wedaesday

20

19

20

21

Thursday

18

19

20

19

Friday

18

20

22

20

Sample

Mean

Range

120

(a) If he sets an upper control limit of 21 and a lower control

limit of 19 around the target value of 20 ounces, the control

chart is based on what value of z?

90

80

1.10

1.00

130

10

Answer:

95

1.20

10

1.45

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 5 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning

Production and Operations Analysis, Seventh Editi…

Operations Management

ISBN:

9781478623069

Author:

Steven Nahmias, Tava Lennon Olsen

Publisher:

Waveland Press, Inc.