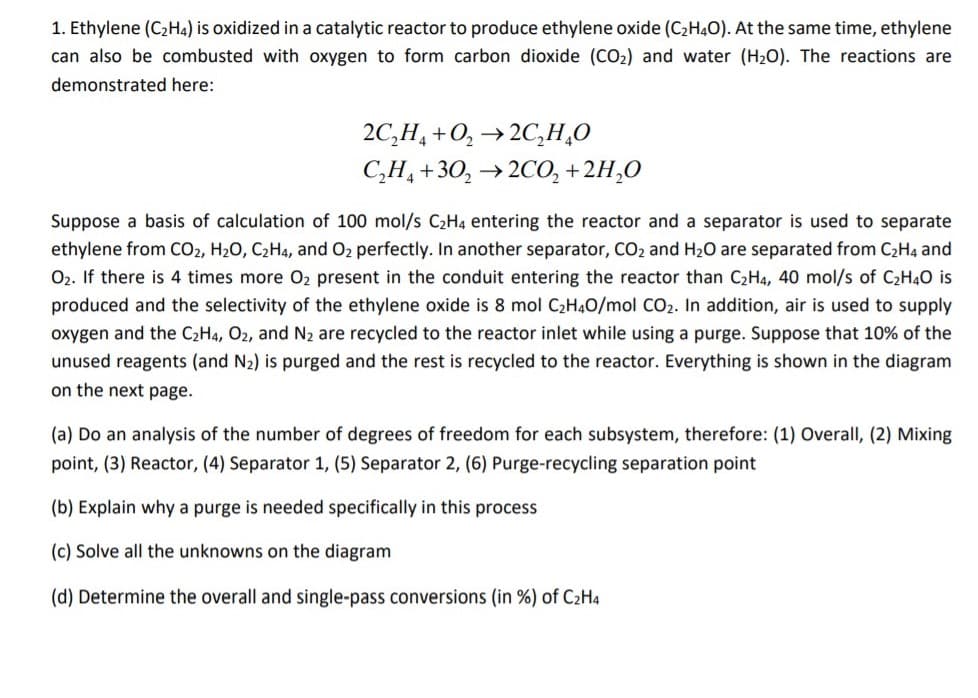

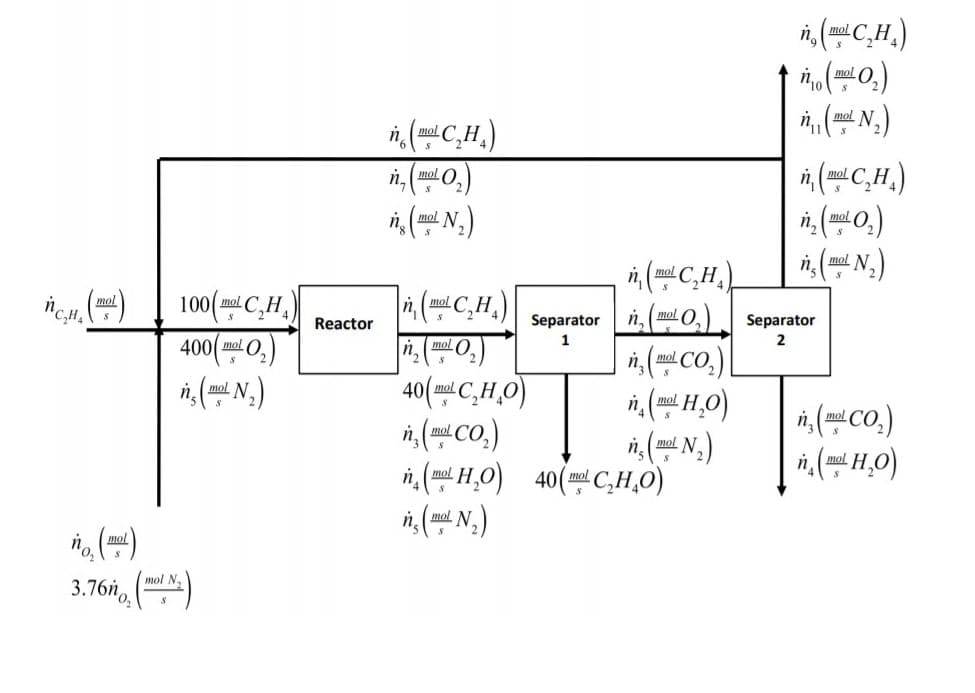

1. Ethylene (C2H4) is oxidized in a catalytic reactor to produce ethylene oxide (C2HẠO). At the same time, ethylene can also be combusted with oxygen to form carbon dioxide (CO2) and water (H2O). The reactions are demonstrated here: 2C,H, +0, →2C,H¸O C,H, +30, →2CO, + 2H,O Suppose a basis of calculation of 100 mol/s C2H4 entering the reactor and a separator is used to separate ethylene from CO2, H20, C2H4, and O2 perfectly. In another separator, CO2 and H2O are separated from C2H4 and O2. If there is 4 times more O2 present in the conduit entering the reactor than C2H4, 40 mol/s of C2H40 is produced and the selectivity of the ethylene oxide is 8 mol C2H4O/mol CO2. In addition, air is used to supply oxygen and the C2H4, O2, and N2 are recycled to the reactor inlet while using a purge. Suppose that 10% of the unused reagents (and N2) is purged and the rest is recycled to the reactor. Everything is shown in the diagram on the next page. (a) Do an analysis of the number of degrees of freedom for each subsystem, therefore: (1) Overall, (2) Mixing point, (3) Reactor, (4) Separator 1, (5) Separator 2, (6) Purge-recycling separation point (b) Explain why a purge is needed specifically in this process (c) Solve all the unknowns on the diagram (d) Determine the overall and single-pass conversions (in %) of C2H4

1. Ethylene (C2H4) is oxidized in a catalytic reactor to produce ethylene oxide (C2HẠO). At the same time, ethylene can also be combusted with oxygen to form carbon dioxide (CO2) and water (H2O). The reactions are demonstrated here: 2C,H, +0, →2C,H¸O C,H, +30, →2CO, + 2H,O Suppose a basis of calculation of 100 mol/s C2H4 entering the reactor and a separator is used to separate ethylene from CO2, H20, C2H4, and O2 perfectly. In another separator, CO2 and H2O are separated from C2H4 and O2. If there is 4 times more O2 present in the conduit entering the reactor than C2H4, 40 mol/s of C2H40 is produced and the selectivity of the ethylene oxide is 8 mol C2H4O/mol CO2. In addition, air is used to supply oxygen and the C2H4, O2, and N2 are recycled to the reactor inlet while using a purge. Suppose that 10% of the unused reagents (and N2) is purged and the rest is recycled to the reactor. Everything is shown in the diagram on the next page. (a) Do an analysis of the number of degrees of freedom for each subsystem, therefore: (1) Overall, (2) Mixing point, (3) Reactor, (4) Separator 1, (5) Separator 2, (6) Purge-recycling separation point (b) Explain why a purge is needed specifically in this process (c) Solve all the unknowns on the diagram (d) Determine the overall and single-pass conversions (in %) of C2H4

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

Question Attached Below!

Transcribed Image Text:1. Ethylene (C2H4) is oxidized in a catalytic reactor to produce ethylene oxide (C2H4O). At the same time, ethylene

can also be combusted with oxygen to form carbon dioxide (CO2) and water (H20). The reactions are

demonstrated here:

2C,H, +0, →2C,H¸0

С,Н, +30, > 2СО, + 2H,0

Suppose a basis of calculation of 100 mol/s C2H4 entering the reactor and a separator is used to separate

ethylene from CO2, H20, C2H4, and O2 perfectly. In another separator, CO2 and H2O are separated from C2H4 and

02. If there is 4 times more 02 present in the conduit entering the reactor than C2H4, 40 mol/s of C2H40 is

produced and the selectivity of the ethylene oxide is 8 mol C2H40/mol CO2. In addition, air is used to supply

oxygen and the C2H4, O2, and N2 are recycled to the reactor inlet while using a purge. Suppose that 10% of the

unused reagents (and N2) is purged and the rest is recycled to the reactor. Everything is shown in the diagram

on the next page.

(a) Do an analysis of the number of degrees of freedom for each subsystem, therefore: (1) Overall, (2) Mixing

point, (3) Reactor, (4) Separator 1, (5) Separator 2, (6) Purge-recycling separation point

(b) Explain why a purge is needed specifically in this process

(c) Solve all the unknowns on the diagram

(d) Determine the overall and single-pass conversions (in %) of C2H4

Transcribed Image Text:mol

(N.)

n, (0.)

mol

mol

mol N

i, (C,H,)

i, (C,H.)

100(ml C,H,

400(m 0,)

mol

mol C

Separator n, (mol O,

Separator

Reactor

n.mol O

i, (mal CO.)

40(m C,H,0)

n,( CO.)

n, (mil H,O) 40(mC,H,0)

n. mol N

i, (Co.)

mol N

()

3.76h, ()

mol N.

Expert Solution

Trending now

This is a popular solution!

Step by step

Solved in 9 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, chemical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The