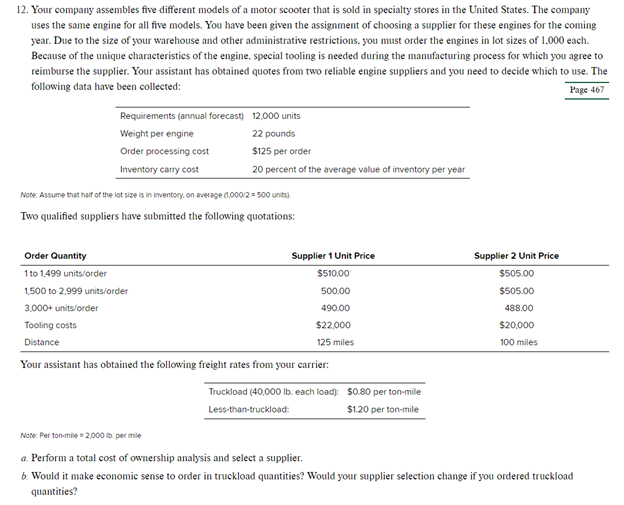

12. Your company assembles five different models of a motor scooter that is sold in specialty stores in the United States. The company uses the same engine for all five models. You have been given the assignment of choosing a supplier for these engines for the coming year. Due to the size of your warehouse and other administrative restrictions, you must order the engines in lot sizes of 1,000 each. Because of the unique characteristics of the engine, special tooling is needed during the manufacturing process for which you agree to reimburse the supplier. Your assistant has obtained quotes from two reliable engine suppliers and you need to decide which to use. The following data have been collected: Page 467 Requirements (annual forecast) 12,000 units 22 pounds $125 per order 20 percent of the average value of inventory per year Weight per engine Order processing cost Inventory carry cost Note: Assume that half of the lot size is in inventory, on average (1,000/2500 units) Two qualified suppliers have submitted the following quotations: Supplier 1 Unit Price $510.00 500.00 Order Quantity 1 to 1,499 units/order 1,500 to 2,999 units/order 3,000+ units/order Tooling costs Distance Your assistant has obtained the following freight rates from your carrier: Truckload (40,000 lb. each load); Less-than-truckload: 490.00 $22,000 125 miles $0.80 per ton-mile $1.20 per ton-mile Supplier 2 Unit Price $505.00 $505.00 488.00 $20,000 100 miles Note: Perton-mile 2,000 lb. per mile a. Perform a total cost of ownership analysis and select a supplier. b. Would it make economic sense to order in truckload quantities? Would your supplier selection change if you ordered truckload quantities?

12. Your company assembles five different models of a motor scooter that is sold in specialty stores in the United States. The company uses the same engine for all five models. You have been given the assignment of choosing a supplier for these engines for the coming year. Due to the size of your warehouse and other administrative restrictions, you must order the engines in lot sizes of 1,000 each. Because of the unique characteristics of the engine, special tooling is needed during the manufacturing process for which you agree to reimburse the supplier. Your assistant has obtained quotes from two reliable engine suppliers and you need to decide which to use. The following data have been collected: Page 467 Requirements (annual forecast) 12,000 units 22 pounds $125 per order 20 percent of the average value of inventory per year Weight per engine Order processing cost Inventory carry cost Note: Assume that half of the lot size is in inventory, on average (1,000/2500 units) Two qualified suppliers have submitted the following quotations: Supplier 1 Unit Price $510.00 500.00 Order Quantity 1 to 1,499 units/order 1,500 to 2,999 units/order 3,000+ units/order Tooling costs Distance Your assistant has obtained the following freight rates from your carrier: Truckload (40,000 lb. each load); Less-than-truckload: 490.00 $22,000 125 miles $0.80 per ton-mile $1.20 per ton-mile Supplier 2 Unit Price $505.00 $505.00 488.00 $20,000 100 miles Note: Perton-mile 2,000 lb. per mile a. Perform a total cost of ownership analysis and select a supplier. b. Would it make economic sense to order in truckload quantities? Would your supplier selection change if you ordered truckload quantities?

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter3: Introduction To Optimization Modeling

Section3.8: A Multiperiod Production Model

Problem 22P

Related questions

Question

100%

Can you assist me with homework chapter 16 question 12. I am having a difficult time understanding. Thank you

Transcribed Image Text:12. Your company assembles five different models of a motor scooter that is sold in specialty stores in the United States. The company

uses the same engine for all five models. You have been given the assignment of choosing a supplier for these engines for the coming

year. Due to the size of your warehouse and other administrative restrictions, you must order the engines in lot sizes of 1,000 each.

Because of the unique characteristics of the engine, special tooling is needed during the manufacturing process for which you agree to

reimburse the supplier. Your assistant has obtained quotes from two reliable engine suppliers and you need to decide which to use. The

following data have been collected:

Page 467

Requirements (annual forecast) 12,000 units

Weight per engine

22 pounds

Order processing cost

$125 per order

Inventory carry cost

20 percent of the average value of inventory per year

Note: Assume that half of the lot size is in inventory, on average (1,000/2 = 500 units).

Two qualified suppliers have submitted the following quotations:

Order Quantity

Supplier 1 Unit Price

1 to 1,499 units/order

$510.00

1,500 to 2,999 units/order

500.00

3,000+ units/order

490.00

Tooling costs

$22,000

Distance

125 miles

Your assistant has obtained the following freight rates from your carrier:

Truckload (40,000 lb. each load):

Less-than-truckload:

Note: Perton-mile 2,000 lb. per mile

$0.80 per ton-mile

$1.20 per ton-mile

Supplier 2 Unit Price

$505.00

$505.00

488.00

$20,000

100 miles

a. Perform a total cost of ownership analysis and select a supplier.

6. Would it make economic sense to order in truckload quantities? Would your supplier selection change if you ordered truckload

quantities?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps with 4 images

Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,