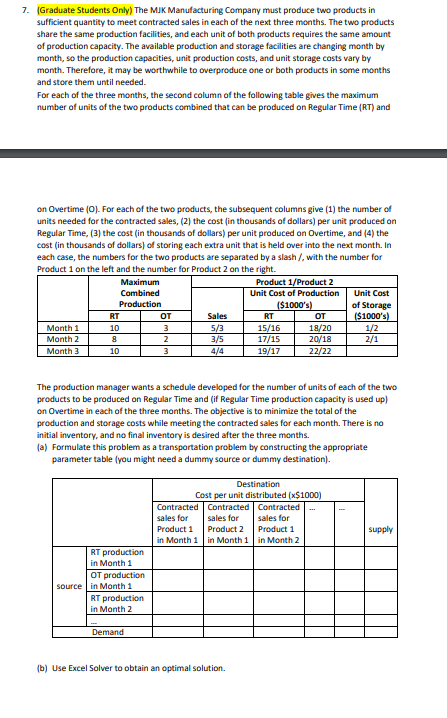

7. (Graduate Students Only) The MJK Manufacturing Company must produce two products in sufficient quantity to meet contracted sales in each of the next three months. The two products share the same production facilities, and each unit of both products requires the same amount of production capacity. The available production and storage facilities are changing month by month, so the production capacities, unit production costs, and unit storage costs vary by month. Therefore, it may be worthwhile to overproduce one or both products in some months and store them until needed. For each of the three months, the second column of the following table gives the maximum number of units of the two products combined that can be produced on Regular Time (RT) and on Overtime (O). For each of the two products, the subsequent columns give (1) the number of units needed for the contracted sales, (2) the cost (in thousands of dollars) per unit produced on Regular Time, (3) the cost (in thousands of dollars) per unit produced on Overtime, and (4) the cost (in thousands of dollars) of storing each extra unit that is held over into the next month. In each case, the numbers for the two products are separated by a slash/, with the number for Product 1 on the left and the number for Product 2 on the right. Month 1 Month 2 Month 3 Maximum Combined Production RT 10 8 10 RT production in Month 1 OT production source in Month 1 RT production in Month 2 OT 3 2 3 Demand The production manager wants a schedule developed for the number of units of each of the two products to be produced on Regular Time and (if Regular Time production capacity is used up) on Overtime in each of the three months. The objective is to minimize the total of the production and storage costs while meeting the contracted sales for each month. There is no initial inventory, and no final inventory is desired after the three months. (a) Formulate this problem as a transportation problem by constructing the appropriate parameter table (you might need a dummy source or dummy destination). Sales 5/3 3/5 Contracted sales for Product 1 in Month 1 Product 1/Product2 Unit Cost of Production ($1000's) Destination Cost per unit distributed (x$1000) Contracted sales for Product 2 RT 15/16 17/15 19/17 Contracted sales for Product 1 in Month 1 in Month 2 (b) Use Excel Solver to obtain an optimal solution. от 18/20 20/18 22/22 Unit Cost of Storage ($1000's) 1/2 2/1 supply

7. (Graduate Students Only) The MJK Manufacturing Company must produce two products in sufficient quantity to meet contracted sales in each of the next three months. The two products share the same production facilities, and each unit of both products requires the same amount of production capacity. The available production and storage facilities are changing month by month, so the production capacities, unit production costs, and unit storage costs vary by month. Therefore, it may be worthwhile to overproduce one or both products in some months and store them until needed. For each of the three months, the second column of the following table gives the maximum number of units of the two products combined that can be produced on Regular Time (RT) and on Overtime (O). For each of the two products, the subsequent columns give (1) the number of units needed for the contracted sales, (2) the cost (in thousands of dollars) per unit produced on Regular Time, (3) the cost (in thousands of dollars) per unit produced on Overtime, and (4) the cost (in thousands of dollars) of storing each extra unit that is held over into the next month. In each case, the numbers for the two products are separated by a slash/, with the number for Product 1 on the left and the number for Product 2 on the right. Month 1 Month 2 Month 3 Maximum Combined Production RT 10 8 10 RT production in Month 1 OT production source in Month 1 RT production in Month 2 OT 3 2 3 Demand The production manager wants a schedule developed for the number of units of each of the two products to be produced on Regular Time and (if Regular Time production capacity is used up) on Overtime in each of the three months. The objective is to minimize the total of the production and storage costs while meeting the contracted sales for each month. There is no initial inventory, and no final inventory is desired after the three months. (a) Formulate this problem as a transportation problem by constructing the appropriate parameter table (you might need a dummy source or dummy destination). Sales 5/3 3/5 Contracted sales for Product 1 in Month 1 Product 1/Product2 Unit Cost of Production ($1000's) Destination Cost per unit distributed (x$1000) Contracted sales for Product 2 RT 15/16 17/15 19/17 Contracted sales for Product 1 in Month 1 in Month 2 (b) Use Excel Solver to obtain an optimal solution. от 18/20 20/18 22/22 Unit Cost of Storage ($1000's) 1/2 2/1 supply

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter7: Nonlinear Optimization Models

Section: Chapter Questions

Problem 56P

Related questions

Question

Transcribed Image Text:7. (Graduate Students Only) The MJK Manufacturing Company must produce two products in

sufficient quantity to meet contracted sales in each of the next three months. The two products

share the same production facilities, and each unit of both products requires the same amount

of production capacity. The available production and storage facilities are changing month by

month, so the production capacities, unit production costs, and unit storage costs vary by

month. Therefore, it may be worthwhile to overproduce one or both products in some months

and store them until needed.

For each of the three months, the second column of the following table gives the maximum

number of units of the two products combined that can be produced on Regular Time (RT) and

on Overtime (O). For each of the two products, the subsequent columns give (1) the number of

units needed for the contracted sales, (2) the cost (in thousands of dollars) per unit produced on

Regular Time, (3) the cost (in thousands of dollars) per unit produced on Overtime, and (4) the

cost (in thousands of dollars) of storing each extra unit that is held over into the next month. In

each case, the numbers for the two products are separated by a slash /, with the number for

Product 1 on the left and the number for Product 2 on the right.

Product 1/Product 2

Unit Cost of Production

($1000's)

Month 1

Month 2

Month 3

Maximum

Combined

Production

RT

10

8

10

RT production

in Month 1

OT production

source in Month 1

RT production

in Month 2

OT

3

2

3

Demand

The production manager wants a schedule developed for the number of units of each of the two

products to be produced on Regular Time and (if Regular Time production capacity is used up)

on Overtime in each of the three months. The objective is to minimize the total of the

production and storage costs while meeting the contracted sales for each month. There is no

initial inventory, and no final inventory is desired after the three months.

(a) Formulate this problem as a transportation problem by constructing the appropriate

parameter table (you might need a dummy source or dummy destination).

Sales

5/3

3/5

4/4

Contracted

sales for

Product 1

in Month 1

RT

15/16

17/15

19/17

Destination

Cost per unit distributed (x$1000)

от

18/20

20/18

22/22

Contracted Contracted

sales for

sales for

Product 1

Product 2

in Month 1

in Month 2

(b) Use Excel Solver to obtain an optimal solution.

Unit Cost

of Storage

($1000's)

1/2

2/1

supply

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps with 4 images

Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,