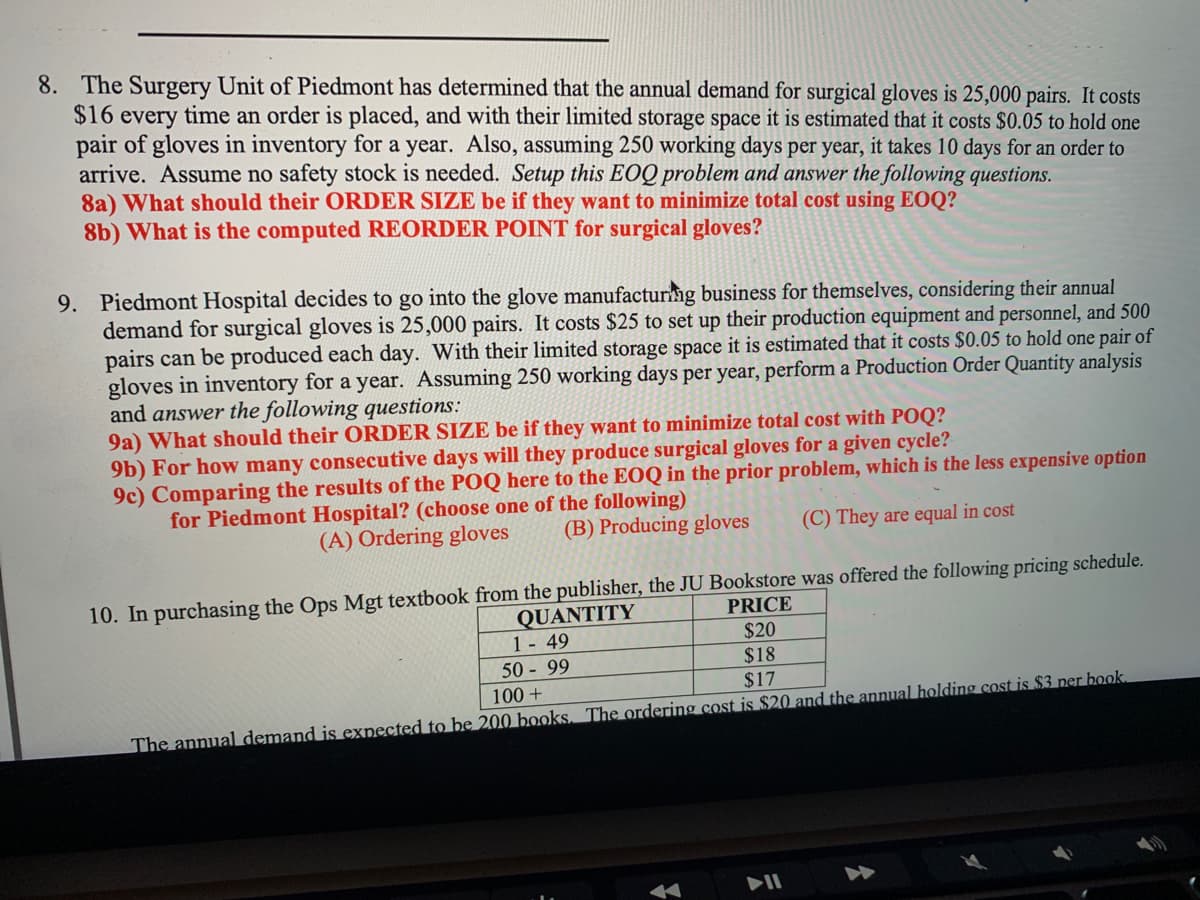

8. The Surgery Unit of Piedmont has determined that the annual demand for surgical gloves is 25,000 pairs. It costs $16 every time an order is placed, and with their limited storage space it is estimated that it costs $0.05 to hold one pair of gloves in inventory for a year. Also, assuming 250 working days per year, it takes 10 days for an order to arrive. Assume no safety stock is needed. Setup this EOQ problem and answer the following questions. 8a) What should their ORDER SIZE be if they want to minimize total cost using EOQ? 8b) What is the computed REORDER POINT for surgical gloves? 9. Piedmont Hospital decides to go into the glove manufacturing business for themselves, considering their annual demand for surgical gloves is 25,000 pairs. It costs $25 to set up their production equipment and personnel, and 500 pairs can be produced each day. With their limited storage space it is estimated that it costs $0.05 to hold one pair of gloves in inventory for a year. Assuming 250 working days per year, perform a Production Order Quantity analysis and answer the following questions: 9a) What should their ORDER SIZE be if they want to minimize total cost with POQ? 9b) For how many consecutive days will they produce surgical gloves for a given cycle? 9c) Comparing the results of the POQ here to the EOQ in the prior problem, which is the less expensive option for Piedmont Hospital? (choose one of the following) (A) Ordering gloves (B) Producing gloves (C) They are equal in cost 10. In purchasing the Ops Mgt textbook from the publisher, the JU Bookstore was offered the following pricing schedule. QUANTITY PRICE $20 $18 $17 The annual demand is expected to be 200 books. The ordering cost is $20 and the annual holding cost is $3 per book. 1 - 49 50-99 100+

8. The Surgery Unit of Piedmont has determined that the annual demand for surgical gloves is 25,000 pairs. It costs $16 every time an order is placed, and with their limited storage space it is estimated that it costs $0.05 to hold one pair of gloves in inventory for a year. Also, assuming 250 working days per year, it takes 10 days for an order to arrive. Assume no safety stock is needed. Setup this EOQ problem and answer the following questions. 8a) What should their ORDER SIZE be if they want to minimize total cost using EOQ? 8b) What is the computed REORDER POINT for surgical gloves? 9. Piedmont Hospital decides to go into the glove manufacturing business for themselves, considering their annual demand for surgical gloves is 25,000 pairs. It costs $25 to set up their production equipment and personnel, and 500 pairs can be produced each day. With their limited storage space it is estimated that it costs $0.05 to hold one pair of gloves in inventory for a year. Assuming 250 working days per year, perform a Production Order Quantity analysis and answer the following questions: 9a) What should their ORDER SIZE be if they want to minimize total cost with POQ? 9b) For how many consecutive days will they produce surgical gloves for a given cycle? 9c) Comparing the results of the POQ here to the EOQ in the prior problem, which is the less expensive option for Piedmont Hospital? (choose one of the following) (A) Ordering gloves (B) Producing gloves (C) They are equal in cost 10. In purchasing the Ops Mgt textbook from the publisher, the JU Bookstore was offered the following pricing schedule. QUANTITY PRICE $20 $18 $17 The annual demand is expected to be 200 books. The ordering cost is $20 and the annual holding cost is $3 per book. 1 - 49 50-99 100+

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter2: Introduction To Spreadsheet Modeling

Section: Chapter Questions

Problem 20P: Julie James is opening a lemonade stand. She believes the fixed cost per week of running the stand...

Related questions

Question

Question 8-9 questions in red

Transcribed Image Text:8. The Surgery Unit of Piedmont has determined that the annual demand for surgical gloves is 25,000 pairs. It costs

$16 every time an order is placed, and with their limited storage space it is estimated that it costs $0.05 to hold one

pair of gloves in inventory for a year. Also, assuming 250 working days per year, it takes 10 days for an order to

arrive. Assume no safety stock is needed. Setup this EOQ problem and answer the following questions.

8a) What should their ORDER SIZE be if they want to minimize total cost using EOQ?

8b) What is the computed REORDER POINT for surgical gloves?

9. Piedmont Hospital decides to go into the glove manufacturing business for themselves, considering their annual

demand for surgical gloves is 25,000 pairs. It costs $25 to set up their production equipment and personnel, and 500

pairs can be produced each day. With their limited storage space it is estimated that it costs $0.05 to hold one pair of

gloves in inventory for a year. Assuming 250 working days per year, perform a Production Order Quantity analysis

and answer the following questions:

9a) What should their ORDER SIZE be if they want to minimize total cost with POQ?

9b) For how many consecutive days will they produce surgical gloves for a given cycle?

9c) Comparing the results of the POQ here to the EOQ in the prior problem, which is the less expensive option

for Piedmont Hospital? (choose one of the following)

(A) Ordering gloves

(B) Producing gloves

(C) They are equal in cost

10. In purchasing the Ops Mgt textbook from the publisher, the JU Bookstore was offered the following pricing schedule.

QUANTITY

PRICE

$20

1 - 49

50-99

100+

$18

$17

The annual demand is expected to be 200 books. The ordering cost is $20 and the annual holding cost is $3 per book.

PII

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 3 steps

Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning

Production and Operations Analysis, Seventh Editi…

Operations Management

ISBN:

9781478623069

Author:

Steven Nahmias, Tava Lennon Olsen

Publisher:

Waveland Press, Inc.