8. Which best defines the gross requirements for a component items a) The forecast customer demand for the component. b) The amount of safety stock needed to buffer against uncertainty. c) The sum of gross requirements for all parents of the components. d) The total demand for the components derived from all immediate parents. 9. Which of the following statements about lot-sizing rules is true? a) The periodic order quantity (POQ) rule seeks to create inventory remnants. bl If the POO rule is used an item's lot size can very each time an order is placed

8. Which best defines the gross requirements for a component items a) The forecast customer demand for the component. b) The amount of safety stock needed to buffer against uncertainty. c) The sum of gross requirements for all parents of the components. d) The total demand for the components derived from all immediate parents. 9. Which of the following statements about lot-sizing rules is true? a) The periodic order quantity (POQ) rule seeks to create inventory remnants. bl If the POO rule is used an item's lot size can very each time an order is placed

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter2: Introduction To Spreadsheet Modeling

Section: Chapter Questions

Problem 20P: Julie James is opening a lemonade stand. She believes the fixed cost per week of running the stand...

Related questions

Question

Answer Theses MCQ question please correctly.

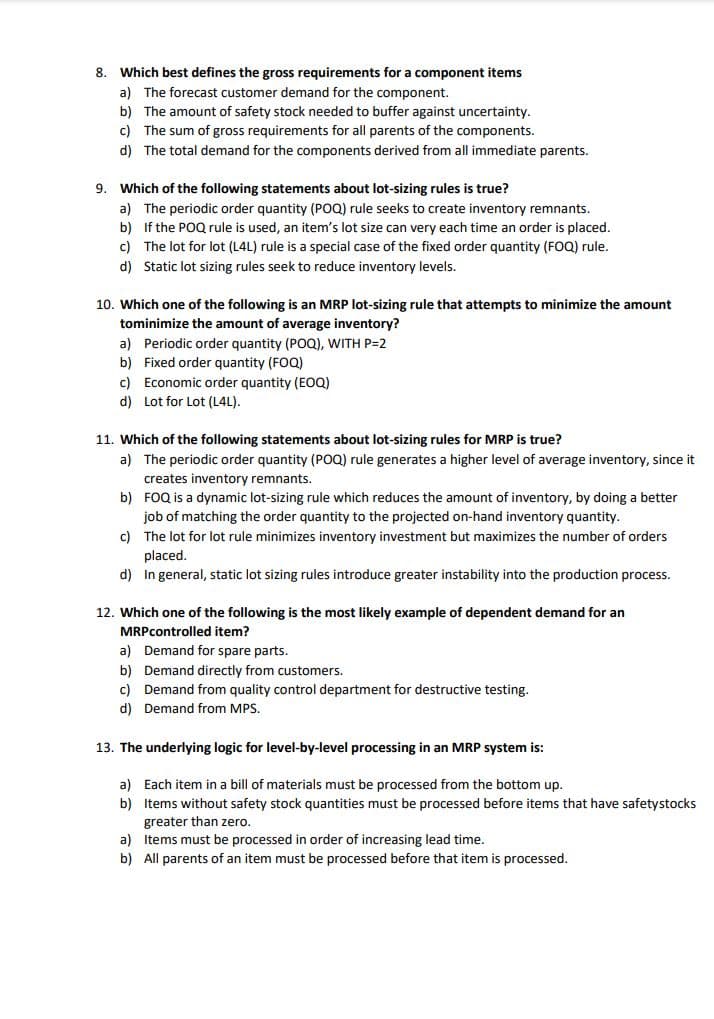

Transcribed Image Text:8. Which best defines the gross requirements for a component items

a) The forecast customer demand for the component.

b) The amount of safety stock needed to buffer against uncertainty.

c) The sum of gross requirements for all parents of the components.

d) The total demand for the components derived from all immediate parents.

9. Which of the following statements about lot-sizing rules is true?

a) The periodic order quantity (POQ) rule seeks to create inventory remnants.

b) If the POQ rule is used, an item's lot size can very each time an order is placed.

c) The lot for lot (L4L) rule is a special case of the fixed order quantity (FOQ) rule.

d) Static lot sizing rules seek to reduce inventory levels.

10. Which one of the following is an MRP lot-sizing rule that attempts to minimize the amount

tominimize the amount of average inventory?

a) Periodic order quantity (POQ), WITH P=2

b) Fixed order quantity (FOQ)

c) Economic order quantity (EOQ)

d) Lot for Lot (L4L).

11. Which of the following statements about lot-sizing rules for MRP is true?

a) The periodic order quantity (POQ) rule generates a higher level of average inventory, since it

creates inventory remnants.

b) FOQ is a dynamic lot-sizing rule which reduces the amount of inventory, by doing a better

job of matching the order quantity to the projected on-hand inventory quantity.

c) The lot for lot rule minimizes inventory investment but maximizes the number of orders

placed.

d) In general, static lot sizing rules introduce greater instability into the production process.

12. Which one of the following is the most likely example of dependent demand for an

MRPcontrolled item?

a) Demand for spare parts.

b) Demand directly from customers.

c) Demand from quality control department for destructive testing.

d) Demand from MPS.

13. The underlying logic for level-by-level processing in an MRP system is:

a) Each item in a bill of materials must be processed from the bottom up.

b) Items without safety stock quantities must be processed before items that have safetystocks

greater than zero.

a) Items must be processed in order of increasing lead time.

b) All parents of an item must be processed before that item is processed.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 4 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning

Production and Operations Analysis, Seventh Editi…

Operations Management

ISBN:

9781478623069

Author:

Steven Nahmias, Tava Lennon Olsen

Publisher:

Waveland Press, Inc.