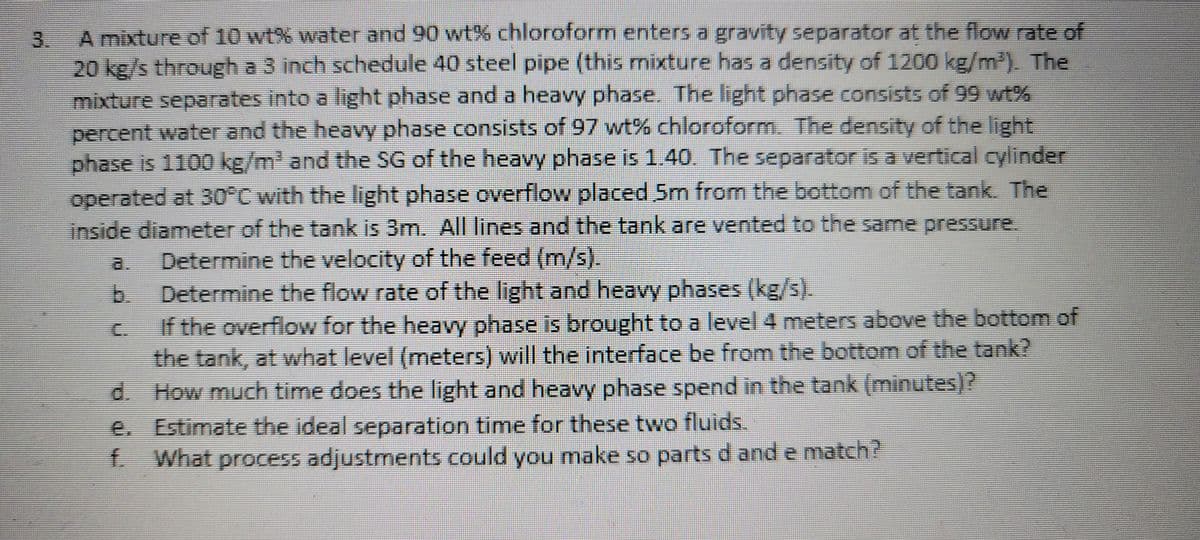

A mixture of 10 wt% water and 90 wt% chloroform enters a gravity separator at the flow rate of 20 kg/s through a 3 inch schedule 40 steel pipe (this mixture has a density of 1200 kg/m³). The mixture separates into a light phase and a heavy phase. The light phase consists of 99 wt% percent water and the heavy phase consists of 97 wt% chloroform. The density of the light phase is 1100 kg/m³ and the SG of the heavy phase is 1.40. The separator is a vertical cylinder operated at 30°C with the light phase overflow placed 5m from the bottom of the tank. The inside diameter of the tank is 3m. All lines and the tank are vented to the same pressure. Determine the velocity of the feed (m/s). Determine the flow rate of the light and heavy phases (kg/s). a. b. C. If the overflow for the heavy phase is brought to a level 4 meters above the bottom of the tank at what level (meters) will the interface be from the bottom of the tank?

A mixture of 10 wt% water and 90 wt% chloroform enters a gravity separator at the flow rate of 20 kg/s through a 3 inch schedule 40 steel pipe (this mixture has a density of 1200 kg/m³). The mixture separates into a light phase and a heavy phase. The light phase consists of 99 wt% percent water and the heavy phase consists of 97 wt% chloroform. The density of the light phase is 1100 kg/m³ and the SG of the heavy phase is 1.40. The separator is a vertical cylinder operated at 30°C with the light phase overflow placed 5m from the bottom of the tank. The inside diameter of the tank is 3m. All lines and the tank are vented to the same pressure. Determine the velocity of the feed (m/s). Determine the flow rate of the light and heavy phases (kg/s). a. b. C. If the overflow for the heavy phase is brought to a level 4 meters above the bottom of the tank at what level (meters) will the interface be from the bottom of the tank?

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

C please!!!!

Transcribed Image Text:A mixture of 10 wt% water and 90 wt% chloroform enters a gravity separator at the flow rate of

20 kg/s through a 3 inch schedule 40 steel pipe (this mixture has a density of 1200 kg/m³). The

mixture separates into a light phase and a heavy phase. The light phase consists of 99 wt%

percent water and the heavy phase consists of 97 wt% chloroform. The density of the light

phase is 1100 kg/m³ and the SG of the heavy phase is 1.40. The separator is a vertical cylinder

operated at 30°C with the light phase overflow placed 5m from the bottom of the tank. The

inside diameter of the tank is 3m. All lines and the tank are vented to the same pressure.

Determine the velocity of the feed (m/s).

Determine the flow rate of the light and heavy phases (kg/s).

If the overflow for the heavy phase is brought to a level 4 meters above the bottom of

the tank, at what level (meters) will the interface be from the bottom of the tank?

d.

How much time does the light and heavy phase spend in the tank (minutes)?

e.

Estimate the ideal separation time for these two fluids.

f What process adjustments could you make so parts d and e match?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 4 steps with 4 images

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The