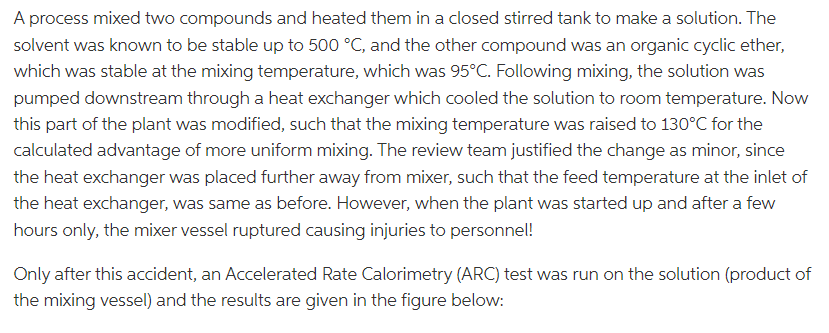

A process mixed two compounds and heated them in a closed stirred tank to make a solution. The solvent was known to be stable up to 500 °C, and the other compound was an organic cyclic ether, which was stable at the mixing temperature, which was 95°C. Following mixing, the solution was pumped downstream through a heat exchanger which cooled the solution to room temperature. Now this part of the plant was modified, such that the mixing temperature was raised to 130°C for the calculated advantage of more uniform mixing. The review team justified the change as minor, since the heat exchanger was placed further away from mixer, such that the feed temperature at the inlet of the heat exchanger, was same as before. However, when the plant was started up and after a few hours only, the mixer vessel ruptured causing injuries to personnel! Only after this accident, an Accelerated Rate Calorimetry (ARC) test was run on the solution (product of the mixing vessel) and the results are given in the figure below:

A process mixed two compounds and heated them in a closed stirred tank to make a solution. The solvent was known to be stable up to 500 °C, and the other compound was an organic cyclic ether, which was stable at the mixing temperature, which was 95°C. Following mixing, the solution was pumped downstream through a heat exchanger which cooled the solution to room temperature. Now this part of the plant was modified, such that the mixing temperature was raised to 130°C for the calculated advantage of more uniform mixing. The review team justified the change as minor, since the heat exchanger was placed further away from mixer, such that the feed temperature at the inlet of the heat exchanger, was same as before. However, when the plant was started up and after a few hours only, the mixer vessel ruptured causing injuries to personnel! Only after this accident, an Accelerated Rate Calorimetry (ARC) test was run on the solution (product of the mixing vessel) and the results are given in the figure below:

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

Transcribed Image Text:A process mixed two compounds and heated them in a closed stirred tank to make a solution. The

solvent was known to be stable up to 500 °C, and the other compound was an organic cyclic ether,

which was stable at the mixing temperature, which was 95°C. Following mixing, the solution was

pumped downstream through a heat exchanger which cooled the solution to room temperature. Now

this part of the plant was modified, such that the mixing temperature was raised to 130°C for the

calculated advantage of more uniform mixing. The review team justified the change as minor, since

the heat exchanger was placed further away from mixer, such that the feed temperature at the inlet of

the heat exchanger, was same as before. However, when the plant was started up and after a few

hours only, the mixer vessel ruptured causing injuries to personnel!

Only after this accident, an Accelerated Rate Calorimetry (ARC) test was run on the solution (product of

the mixing vessel) and the results are given in the figure below:

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The